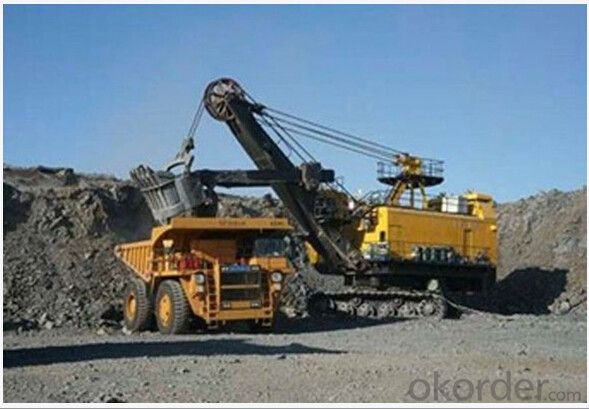

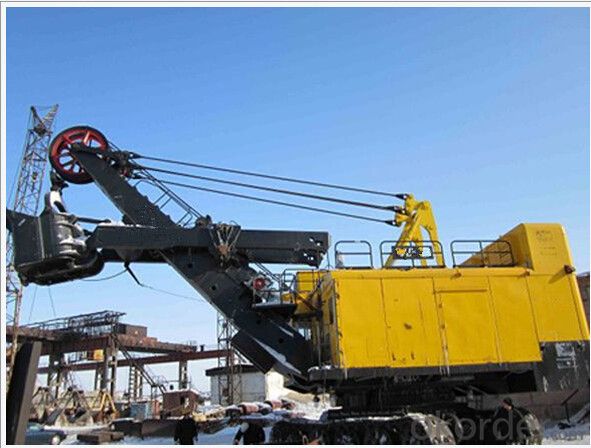

WK-10C Mining Excavator for mining on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WK-10C excavators are suitable for 10 million MT mining use, to be used in combination with 80-154 MT dumpers or 100 MT dumping trains.

Product specifications:

•Gear-rack crowding, powerful penetration, high efficiency;

•AC IGBT drive.

Technical Spec. of WK-10C | |||

Dipper (standard) | 12m³ | Hoist motor, rated power | 2x315kW/690VAC |

Dipper capacity | 8m³ -16m³ | Digging radius (max) | 18.90m |

Hoist speed | 1.50m /s | Height of cut (max) | 13.53m |

Crowd speed | 0.58m /s | Dumping radius (max) | 16.25m |

Propel speed | 0.96km/h | Dumping height (max)-door open | 8.60m |

Max. hoist force | 1110kN | Depth of cut | 2.20m |

Max. crowd force | 541kN | Working weight | 490t |

Max. gradeability | 13° | Theoretical productivity | 1490m³ /h |

We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: Can I use excavator substrate for my leopard gecko?

- No I wouldn't. The substrate i recommend is reptile carpet. Its easy to wash....... comfortable....... and Light and easy! And your Leopard gecko cant be harmed by it. But Excavator substrate is cool. They can burrow in it but what if you want to get your leopard gecko out but you cant because he is in the burrow? Or if he gets stuck. These are questions you want to think about it. Really i dont have anything against that substrate........soooooo I guess it would be fine to use. But in my opinion i would use Reptile carpet. I hope my answer helped you! IF you have any questions feel free to contact me!

- Q: what machines, or devices or ANYTHING uses hydraulics or pneumatics? i need at least 5!

- A back hoe (or any heavy equipment) uses hydraulics. Most jack hammers use pneumatics

- Q: I saw a photo of vacant lots in a very poor downtown neighborhood of Gary, Indiana, where huge buildings that had once housed big department stores (with full basements) had been torn down. I'm curious about how this is done, especially on the cheap: Is debris (bricks, plaster, etc.) from torn-down buildings ever buried to fill the hole, or is there nothing but dirt under these fields and parking lots? Kind of a silly question -- but I can't imagine where an impoverished city would get tons of dirt from, and I'm wondering if they simply pulled the buildings down and covered everything with dirt -- if that's ever done.

- Actually a very good question. When the use an excavator to demolish these buildings or even a wrecking ball or explosives, they normally clear out all demolition debris from the building. Its considered trash and not allowed to remain at the site. Generally they will also remove the foundation. With the foundation removed the site has more value for future use. The demolition debris most often goes to the dump. Some companies do recycle industrial buildings for the metals and concrete. The only time you can't is when the materials are contaminated. On occasion, I know of businesses that have torn down a buiding, but left the slab behind. Generally you will expect to find that the ground under the building is contaminated, By leaving the concrete, less rainwater will penetrate the ground. This slows the amount of polution in the ground water. Debris is never used to fill the building (at least not legally). Really if you think of it, they are deconstructing the building. Its pretty much the opposite of building it. The biggest difference with construction you are careful that your finished work looks nice. Demolition on the other hand you only care that the site looks pristine when you leave. On a final note, I saw a program about people who make a living removing antique fixtures, windows, knobs, doors, etc. from old buildings to be resold for restoration or speciality work. They will do this prior to a renovation. Some fixtures from old home are buildings can be very valuable.

- Q: i have three questions.the first situation is:person A plays somethingperson B plays an instant in RESPOND to person A's creatureQEUSTION : can person A play a SORCERY in RESPOND to person B's instant?the second question:what is the difference between the LEGEND rule and the PLANESWALKER rule?the third situation:person A plays halimar excavatorperson A then plays a jwari to put it in as a halimarperson B responds to the jwari and plays path to exile(halimar removed)person A plays another jwari in response to path to exilemy assumption is that the last jwari played will come in as a halimar, then the one on the field will be removed due to path to exile. then the first jwari played will come in as a halimar since there is a jwari(halimar) on the field.is this correct since the text of jwari says come in to play as any ally on the battle field? (not targeting any allies on the battlefield)

- First question: No. Until the entire stack resolves, only an instant could be played to respond to player B's response. Second: legend rule destroys permanents with the same name. The planeswalker rule destroys planeswalkers with the same sub-type. For example, Chandra nalaar and Chandra ablaze share the same subtype (planeswalker - CHANDRA). Third: A's first jwari will come into play as a halimar. If B responds to it by exiling halimar, the first jwari will still come in as a copy of halimar. Player A cannot respond to path by playing a creature unless he or she plays the creature after the stack with path resolves. If there is a jwari that copied halimar on the field and A plays another jwari, he or she can copy the jwari to become a second halimar because the first jwari is a copy of an ally, thus it takes on the creature type ally

- Q: Kato 450 excavator multiple

- Kato 450 operating weight (kg):11600 (1) model: MITSUBISHI Mitsubishi 4D31T (2) bucket rod digging force (kN):53.9 (3) bucket digging force (kN):75.5 (4) origin: Japan (5) bucket capacity (square):0.22-0.55

- Q: Hitachi 120 excavator size?

- Basic parameterWhole machine quality (Kg):12200Standard bucket capacity (M3):0.52Rated power (HP/KW):63main performanceWalking speed (Km/h):5.5/3.4Slew rate (RPM):13.7Bucket digging force (Kg):99Standard track width (mm):500Bucket digging force (Kg):65EngineModel: ISUZU CC-4BG1TCRated speed (RPM):1950Working rangeMaximum mining depth (mm):5570Maximum unloading height (mm):6160Maximum radius of excavation (mm):8270Fuel tank volume (L):250Digging machine sizeFull length (mm):7610Full width (mm):2500Full height (mm):2680

- Q: We aren't looking for any fancy fence or tile or lights or a diving board (in fact we don't want lights or a diving board, and we were going to use a manual cover). So we would like to know how much all this would cost initially and how much it would cost to install. I live in Naperville IL., and help would be appreciated, thanks.

- bypass on your community actual sources brokers and they commonly have listings of condo homes. inspect their on-line web pages to verify in the journey that they have got an favourite condo charges on there on your area. look in community newspapers or nationwide newspaper for actual sources classified ads on your area.

- Q: Im doin a CERT 3 in civil Construction and I Gain a Excavator TicketSkid Steer TicketBackhoe TicketI have HR licence White Card Traffic Controlle Ticket and cant Get a Job How I Gain experience When I cant Get a Go ???

- Join the Operating Engineers Union. google it.

- Q: I don't want to dig the entire area (15-18 foot circle) with just a shovel. I can't afford a bobcat, so will a tiller or something like that be good to rent for the day from an equipment rental place? My yard slopes some, so I have to dig up a couple of feet on one side to make it level.

- It would be best and economical to rent a bobcat for a day for about 400-450.00 a day and level off your land to insure that the pool would be level. Or contact your local Landscaper and Design Team and they ususally will have a bobcat ..But they Will CHarge Outrageously. Or Why wont you let the pool people do it for you..They probably will have to contract out..But it will be done professionaly. Unfortunately There are some things that We as Homeowners Must never try to tackle. good luck =}

- Q: excavator tooth point is vulnerable to break,what can I do?

- the teeth of the excavator are replaceable. They make stronger teeth for different applications. Get some good rock teeth, instead of the flat bottom ones you probably have on now.

Send your message to us

WK-10C Mining Excavator for mining on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords