Wide Aluminum Roof Coil - Color Coating Aluminum Coil 3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminum Coil 3003 for Decoration

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coating Aluminum Coil 3003 for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil 3003 for Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

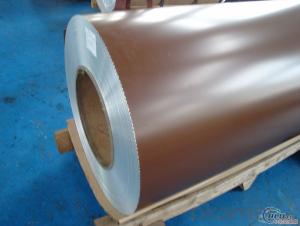

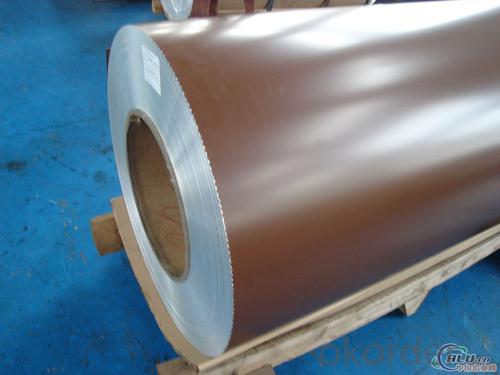

5. Image of Color Coating Aluminum Coil 3003 for Decoration

6. Package and shipping of Color Coating Aluminum Coil 3003 for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any limitations to the minimum coil width of aluminum coils?

- Yes, there are limitations to the minimum coil width of aluminum coils. These limitations depend on various factors such as the type and thickness of the aluminum, the specific manufacturing process, and the equipment used. Generally, the minimum coil width is determined by the capabilities of the rolling mills or slitters used in the production process. These machines have certain minimum width settings that cannot be exceeded. Additionally, extremely narrow coil widths may pose challenges in terms of handling, transportation, and processing.

- Q: What’s the production standard of aluminum coil?

- GB/T3880-2006 mechanical standard GB/T3190-1996 chemical standard

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Aluminum coils usually have restrictions on their thickness. The specific restrictions vary depending on the intended use and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired end product. Applications that require flexibility, such as foils or flexible packaging materials, often prefer thinner coils. Conversely, industries like construction or automotive, where strength and durability are crucial, commonly use thicker coils. Availability and cost of raw materials may also limit the thickness of aluminum coils. Manufacturers must adhere to these restrictions to guarantee the quality and performance of the final product.

- Q: Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- Yes, you can use two sensors to measure thickness, either contact sensor or laser sensor

- Q: Hey! I have an Aluminum MacBook (2.4 GHz Core 2 Duo, 9400m graphics processor), and I'm wondering whether it's worth updating to the new 2011 13 MacBook Pro. I'm mainly looking for two things: 1. What would be the difference between the 2.4 GHz Core 2 Duo, and the 2.3 GHz i5, and 2. What would be the difference between the 9400m and the HD 3000 Graphics?Thanks! :)

- The macpro is the better machine, but for most people the difference would be negligible. your aluminum is still MORE than good enough for almost all people. What are you using it for? If you're into CAD, by all means upgrade. But if you're just surfing the net, save your money. HD3000 is actually worse graphics, but the rest of the machine is better EDIT: AGAIN, it depends on what you are using it for!!! Despite using additional details, you never once discussed how it is to be used. If you read the post, it says, for most people the difference would be negligible. IF your needs are resource intensive, you might need to replace it. If your needs are not resource intensive, you can save your money. For example, I don't need to buy a new car every year, I usually make it last 5-6 years. But my computing requirements are high enough where I replace my laptops every two years and desktops alternating years so I always have a machine that is less than a year old. MOST people squeeze 4 or more years out of a computer. If you are a general ed, humanities or undeclared your aluminum would suit you just fine thgouh your lower 2 years even though it is older. You could then get a new computer for your upper division. If you were a engineering or architecture student, I'd upgrade after first year courses, If you're in business or engineering, get a PC, if you're in architecture, journalism, music or design get a mac. Any other major, it really doesn't matter. Good luck in school!

- Q: How are aluminum coils tested for thickness and flatness?

- Aluminum coils are tested for thickness and flatness using various methods to ensure they meet the required specifications. One common method is the non-destructive eddy current testing, which involves passing an alternating current through a coil and measuring the changes in the magnetic field caused by eddy currents induced in the aluminum. These changes can be used to determine the thickness of the coil. In addition to eddy current testing, ultrasonic testing is also employed to measure the thickness of aluminum coils. Ultrasonic waves are sent through the coil, and the time it takes for the waves to bounce back is measured to determine the thickness. This method is highly accurate and can identify any variations in thickness across the entire coil. To assess the flatness of aluminum coils, a straight edge or a laser beam is often used. The coil is placed on a flat surface, and the straight edge or laser beam is placed across the surface of the coil. Any deviations from a perfectly flat surface can be easily identified by observing the gaps or irregularities between the coil and the straight edge or laser beam. In some cases, advanced technologies like laser profilometry can be used to create a three-dimensional map of the surface of the coil, allowing for a comprehensive analysis of its flatness. This method provides highly detailed information about any variations in flatness across the coil's surface. Overall, aluminum coils undergo rigorous testing procedures to ensure their thickness and flatness meet the required standards. These tests are vital in maintaining the quality and reliability of aluminum coils, especially in applications where precision and consistency are of utmost importance.

- Q: How are aluminum coils used in the production of architectural structures?

- Aluminum coils are used in the production of architectural structures as they provide a lightweight and durable material for various applications. These coils can be formed into different shapes and sizes to create components like siding, roofing, and window frames. The versatility and corrosion resistance of aluminum make it an ideal choice for architectural projects, ensuring long-lasting and aesthetically pleasing structures.

- Q: metals an aluminum can is made of, cast aluminum, 6160 aluminum, sheet aluminum

- the aluminum is alloyed with various metals to change the characteristics of the aluminum the link below shows a table showing the various chemical/metals added to aluminum to make different alloys

- Q: This question asks for the distinctions between a single-layer aluminum coil and a multilayer aluminum coil, focusing on their structure and potential applications.

- <p>A single-layer aluminum coil consists of a single sheet of aluminum wound into a roll, while a multilayer aluminum coil is made up of multiple sheets of aluminum stacked and wound together. Single-layer coils are simpler in structure and are often used for applications requiring less complexity, such as basic insulation or simple wrapping. Multilayer coils, on the other hand, offer increased strength and can provide better insulation properties due to the multiple layers. They are also used in applications where space is limited, as they can be more compact. Additionally, multilayer coils can be tailored for specific heat transfer or electrical conductivity needs by varying the thickness and composition of the layers.</p>

- Q: Can aluminum coils be painted or coated?

- Absolutely! It is entirely possible to paint or apply a coating to aluminum coils. Aluminum, being a remarkably adaptable material, can be adorned with a diverse range of finishes to elevate its aesthetic appeal and safeguard it against corrosion. The typical procedure for painting or coating aluminum coils entails cleansing and prepping the surface, administering a primer, and subsequently applying the desired paint or coating. The selection of paint or coating relies on the desired outcome and the specific purpose of the aluminum coil.

Send your message to us

Wide Aluminum Roof Coil - Color Coating Aluminum Coil 3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords