Goodman Aluminum Coils - Color Coating Aluminum Coil 1050 3003 for Curtain Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

Name | 3003 Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

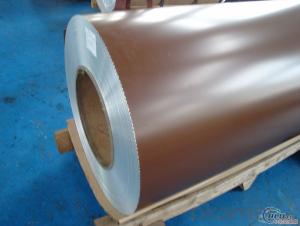

5. Image of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

6. Package and shipping of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils play a key role in enhancing the energy efficiency of appliances. The use of aluminum in coil form allows for efficient heat transfer, which is essential for appliances that require cooling or heating mechanisms. Firstly, aluminum coils have excellent thermal conductivity. This means that they can quickly absorb and dissipate heat, resulting in more efficient cooling or heating processes. This is especially important in appliances such as refrigerators, air conditioners, and heat pumps, where effective heat transfer is crucial for maintaining the desired temperature. Moreover, aluminum coils are lightweight yet durable, making them an ideal choice for energy-efficient appliances. The lightweight nature of aluminum reduces the overall weight of the appliance, which leads to lower energy consumption during transportation and installation. Additionally, the durability of aluminum ensures a longer lifespan for the appliance, reducing the need for frequent maintenance or replacement. Furthermore, aluminum is highly resistant to corrosion, which is a common issue in appliances that involve contact with water or moisture. By using aluminum coils, manufacturers can ensure the longevity and reliability of the appliance, thus contributing to energy efficiency by reducing the need for repairs or replacements. Lastly, aluminum is a highly recyclable material. Using aluminum coils in appliances promotes sustainability and reduces the environmental impact. By choosing energy-efficient appliances that incorporate aluminum coils, consumers can support the circular economy and contribute to a more sustainable future. In conclusion, aluminum coils greatly contribute to the energy efficiency of appliances. Their excellent thermal conductivity, lightweight yet durable nature, corrosion resistance, and recyclability make them an ideal choice for enhancing the performance and sustainability of energy-efficient appliances.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum has a certain level of elasticity and ductility, which allows it to be bent or shaped to a certain extent. However, excessive bending or shaping can lead to cracking, deformation, or even breakage of the aluminum coils. Additionally, the thickness and temper of the aluminum coils can also affect their ability to be bent or shaped. Therefore, it is important to consider these limitations when working with aluminum coils to ensure their structural integrity is maintained.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: How are aluminum coils formed into different shapes and profiles?

- Aluminum coils are formed into different shapes and profiles through a process known as aluminum coil slitting and forming. This involves passing the coil through a series of rollers and dies that apply pressure and force to shape the metal into the desired form. The specific shape and profile are determined by the design of the rollers and dies used in the process.

- Q: What are the different surface treatments available for aluminum coils?

- There are several surface treatments available for aluminum coils, each with its own benefits and applications. Some of the common surface treatments include: 1. Mill Finish: This is the standard untreated surface of aluminum coils. It has a dull appearance and is suitable for applications where aesthetics are not a priority, such as industrial or structural uses. 2. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum coils. This treatment enhances the corrosion resistance, durability, and appearance of the coils. Anodized aluminum coils are commonly used in architectural applications, such as building exteriors or window frames. 3. Paint Coating: Aluminum coils can be coated with various paints to improve their appearance, protect against corrosion, and provide additional functionality such as heat reflection or insulation. Paint coatings can be applied in different thicknesses and finishes, ranging from standard coatings for general use to specialized coatings for specific applications like automotive or aerospace industries. 4. Brushed Finish: This treatment involves brushing the surface of aluminum coils with abrasive materials to create a textured finish. Brushed aluminum coils have a distinct pattern and are often used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or improve their functionality. The embossing process alters the surface of the coils, creating a raised or recessed design. Embossed aluminum coils are commonly used in architectural, automotive, or packaging applications. 6. Laminating: Aluminum coils can be laminated with various materials, such as films or foils, to provide additional protection, insulation, or decorative effects. This treatment can enhance the appearance, durability, or functionality of the coils, depending on the type of laminating material used. These are just a few examples of the surface treatments available for aluminum coils. The choice of treatment depends on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, or functionality. It is important to select the appropriate surface treatment to ensure the desired performance and longevity of the aluminum coils in their intended use.

- Q: Can aluminum coils be used for automotive heat shields?

- Automotive heat shields can indeed utilize aluminum coils. Aluminum, known for its outstanding thermal conductivity and high melting point, is frequently employed as a heat shield material. Its lightweight nature and remarkable resistance to corrosion make it particularly well-suited for automotive purposes. By effortlessly molding aluminum coils into the desired configuration, effective heat insulation can be attained, safeguarding delicate components from the engine or exhaust system's excessive heat. Moreover, aluminum is cost-efficient and easily accessible, contributing to its widespread preference as an automotive heat shield material.

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: Are aluminum coils suitable for insulation purposes?

- Indeed, aluminum coils are well-suited for insulation purposes due to their exceptional heat and electricity conductivity. This quality makes them a perfect selection for insulation applications. Aluminum coils find utility in a wide range of uses such as HVAC systems, refrigeration units, and electrical wiring. Typically, these coils are coated with an insulating material like polyurethane foam or fiberglass to augment their insulation capabilities. The amalgamation of aluminum and insulation works wonders in impeding the transfer of heat or cold, thereby providing superb thermal insulation. Moreover, aluminum is lightweight, sturdy, and resistant to corrosion, rendering it a dependable choice for long-lasting insulation requirements.

- Q: 94 f150. have the stock wheels which are weathered and dull. whats a good way to bring the shine back? some of the original coating is there ,most is gone. tried mothers aluminum wheel polish,does nothing. is it wise to use a wire wheel in a drill to get down to just the aluminum? the wheels are those with the center plastic cap with holes around the outer edge.thanks for any info

- Get a couple of those Mothers power balls .If the clear coat is coming off Then dirt is embedded in the rim The best way is to have them polished by a pro .If thats not the route you want to go ,the power ball is about the only thing that can help you out and for much cheaper than having a pro do it .Not to mention doing it by hand just sucks .But it would take two at least to do all 4 wheels Then the polish will do what its advertised to do or use any polish you want You will need to at least remove the wheel off the truck for the best results If you strip the rims or use acidic cleaners to remove the remaining clear coat It may take more materials Like polish ,Pads,or the power ball thing Cause it will leave a raw aluminum surface which usually requires more time and labor to polish out DON'T WIRE WHEEL THE RIMS OKAY YOU WILL SCRATCH THEM SO DEEP YOU WILL RUIN THEM NO ABRASIVE MATERIALS ARE TO BE USED ON A ALUMINUM RIM NOT EVEN A WIRE WHEEL OF ANY TYPE OR MATERIAL SHOULD BE USED ON THE RIM what you'll do is make them uglier Cause pitting strip the surface leaving a porous and uneven surface Which corrosion likes to form on .Thats the worst and the wrong way to clean aluminum and even steel sometimes depending on what it is But NEVER aluminum

Send your message to us

Goodman Aluminum Coils - Color Coating Aluminum Coil 1050 3003 for Curtain Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords