White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

PU Conveyor Belt

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

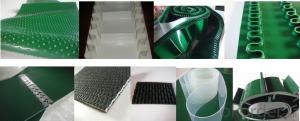

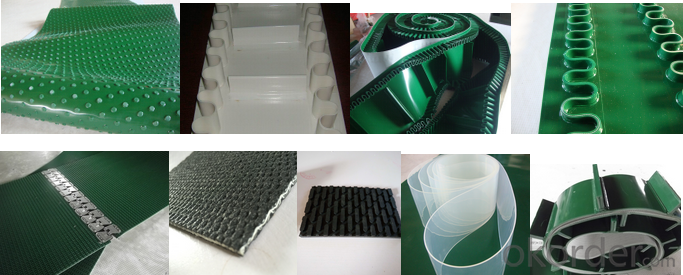

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Just contact us freely if you need any PVC/PU conveyor belt,thank you!

- Q: Are olive nets compatible with mechanical olive harvesters?

- Yes, olive nets are compatible with mechanical olive harvesters. These nets are used to collect the olives that are mechanically shaken from the tree branches during the harvesting process. The nets are spread beneath the trees, allowing the olives to fall onto the nets, making it easier to collect and transport them efficiently.

- Q: What is the most effective way to reduce the environmental pollution caused by plastic bags?

- First, take the paper instead of plastic. At present, our country also has the practice of producing disposable tableware with cane and straw as raw materials, but it is still in the experimental stage.Two, biodegradable plastics are adopted.

- Q: How does an olive net affect the tree health and growth?

- An olive net can have both positive and negative impacts on the health and growth of an olive tree. On one hand, the net provides protection from birds and other animals that may feed on the olives, reducing crop losses and potential damage. This can promote better fruit production and overall tree health. On the other hand, the net can limit airflow and sunlight penetration, potentially leading to increased humidity and reduced photosynthesis. These factors can negatively impact the tree's growth and make it more susceptible to diseases. Therefore, proper management and periodic removal of the olive net are crucial to maintain a balance between protection and the tree's overall health and growth.

- Q: Do olive nets affect the nutritional value of the olives?

- No, olive nets do not affect the nutritional value of the olives.

- Q: Can olive nets be used for olive trees in regions with high bird populations?

- Yes, olive nets can be used for olive trees in regions with high bird populations. Olive nets are specifically designed to protect olive crops from bird damage by creating a physical barrier. They are commonly used in areas where bird populations are high to prevent birds from accessing and feeding on the olives.

- Q: The use of various plastic materials

- AS (SAN) acrylic styrene transparent adhesiveAS is acrylonitrile (A), styrene (S) copolymer, weather resistant medium, not by the high humidity environment, ability, general oil, detergent and mild alcohol, poor fatigue resistance, not easy to crack due to stress, material quality high transparency, good liquidity in ABS.Suitable plastic products: tray, cups, cutlery, toothbrush, refrigerator cabinet, knob, lighting accessories, accessories, instrument mirror, packing box, stationery

- Q: Can olive nets be used in combination with pruning?

- Yes, olive nets can be used in combination with pruning. Pruning helps maintain the shape and health of olive trees, and using nets during the pruning process can help collect the pruned branches and leaves, making cleanup easier. Additionally, olive nets can also be used during the harvest season to catch the falling olives, ensuring that none are lost and facilitating the collection process.

- Q: How does an olive net affect the overall fruit flavor in the olive grove?

- An olive net can have a positive impact on the overall fruit flavor in an olive grove. By placing the netting over the trees, it helps protect the olives from direct sunlight and excessive heat, which can lead to uneven ripening and a decrease in flavor quality. The netting also acts as a barrier, preventing birds and other animals from accessing the fruit, thus reducing the risk of damage or loss. As a result, the olives can fully develop their flavors, resulting in a more consistent and enhanced taste in the olive grove.

- Q: EVA plastic products poisonous?

- EVA plastic products are non-toxic.Ethylene vinyl acetate copolymer, referred to as EVA. Ethylene vinyl acetate (VA) content in 5%-40%, and polyethylene (PE) compared to EVA due to the molecular chain of the vinyl acetate monomer, thereby reducing the high crystallinity, improved toughness, impact resistance, filler compatibility and heat sealing performance, is widely used in foam material, functional films, packaging mold, hot melt adhesive, wire and cable and toys and other fields.

- Q: Are olive nets safe for beneficial insects?

- Yes, olive nets can be safe for beneficial insects. These nets are designed to protect the olives from pests and birds without causing harm to beneficial insects. The mesh size of the nets is typically small enough to prevent insects from getting trapped or tangled, allowing them to freely navigate and carry out their pollination or pest control activities. Additionally, some olive nets are made of materials that are specifically designed to be insect-friendly, allowing them to easily crawl or fly through the netting.

Send your message to us

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords