Welding Electrodes Factory Supply Directly E 6013 BS 639 E4322R21

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Welding Rod Descrition

CLASSIFICATION : AWS/SFA-5.1: E 6013 , BS 639 E4322R21,IS-814: ER 4222,DIN 1913 E 4322R322

APPROVAL: BIS, DNV, IRS

CHARACTERISTICS : The electrode is characterized by smooth and stable arc, low spatter, easy slag detachability, fine rippled bead appearance, weld deposit possesses good chemical and mechanical properties.

APPLICATION :

1) Suitable for tank & vessels.

2) General fabrication.

3) Vehicles.

4) Railway wagons and machinery.

5) Ship building construction, light structural steel works

6) Storage tanks etc.

RE-DRY CONDITION : Re-Dry the electrode at 120°C for 30-60 minutes, for best results.

2.Main Features of Welding Rod

• All-position electrode for the welding of mild steel.

• Excellent choice for sheet metal lap and fillet welds

• Easy slag removal. low smoke.

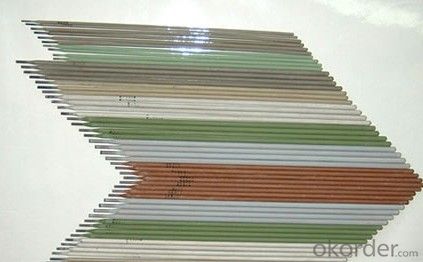

3.Welding Rod Images

4.Welding Rod Specification

Mechanical Properties of Deposited Metal

Test Item | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) | KV2(J) |

Guarantee Value | ≥420 | ≥330 | ≥17 | -(normal temperature) | -(0℃) |

Reference Current (AC, DC)

Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

Length(mm) | 300 | 300(350) | 350 | 400 | 400 |

Welding Current (A) | 40~70 | 55~95 | 80~130 | 120~180 | 160~230 |

V-up, OH | 35~60 | 45~90 | 60~120 | 100~160 | 120~200 |

5.FAQ

Q:Are you factory?

A:Yes, we are factory not shell company. So we can promise good prices and best quality. Welcome you to visit our factory.

Q: What's the delivery time?

A: For products in stock, we can ship it within 7 days after receiving your payment. For custom order, within 24 tons, production time is 20-30 days after confirmed every details.

Q: What about the warranty?

A: We are very confident in our products, and we pack them very well to make sure the goods in well protection.

- Q: One millimeter thick iron direct current welding machine welding 3.2 electrode, need much current?

- 1, 3.2 electrode obviously thicker; should use less than 2.5 diameter of small welding rod;2 、 welding electrode and current matching empirical parametersWelding rod diameter 1.6, 2, 2.5, 3.2, 4, 5, 5.8Current (A) ranged from 25~4040 to 6050~80100 to 130160~210200 to 270260~300This is the experience of welding current, welding, horizontal welding, overhead welding welding current should be smaller than usual 10% ~ 20%.Exp is the confirmation at the time of the experiment. Therefore, before the formal welding, the welding sample should be taken, and the welding current should be obtained to get a solid and beautiful bead.

- Q: 400A DC inverter welding machine, suitable for long welding electrode

- Diameter 4 electrode.Inverter welding machine load rate is generally 60%, 60%, load rate of about 250 or above. Electrode selection current formula is the diameter of the welding rod x (33-55) times = welding current.220 the maximum electrode current is about 4. Current output of welding machine.

- Q: What type of welding rod is needed for the construction of three grade steel bars used in construction?

- Three grade steel is welded with J502 (E5002) structural steel electrode, and AC DC welder can.Three rebar: the new standard name for HRB400 steel, three steel for the old, as a kind of hot rolled ribbed bar. In construction, three - grade rebar is called the past.The steel manufacturers in China are mainly distributed in the north and northeast, North China, Tang Gang, such as Shougang steel, bearing steel, Shanxi steel, Baoding iron and steel Zhongyang Puri, northeast regions such as northern Taiwan, Fushun Steel resistant, etc., these two regions accounted for more than 50% of the total output of thread steel.The difference between round bar and round bar is that the surface has longitudinal ribs and transverse ribs, usually with two longitudinal ribs and transverse ribs uniformly distributed along the length direction. The rebar is a kind of small section steel, mainly used for the skeleton of reinforced concrete construction members. In use, some mechanical strength, bending deformation property and welding performance are required. The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q: Welding specification whether welding rod needs experiment

- Enterprises need: welding rod, welding flux, welding wire must be dry, heat preservation treatment, and need to do some process evaluation, can determine whether the welding rod suitable for such welding, process evaluation is more important.

- Q: How do you know it's a white steel electrode?

- White steel electrode, stainless steel electrode is generally refers to many kinds of stainless steel, such as 30403-30408, 32310S, 31603, 31608, 1CR13 and so on, using different types of electrode, stainless steel electrode used in general are: 102, 022, 132, 042, 002, 132 different types of.

- Q: What does "E7016" mean? What should I pay attention to when welding? Can I weld the pressure vessel (pressure 1Mpa)?

- E stands for welding rod, 70 represents tensile strength of weld metal, 700MPa is 1, welding rod is suitable for all position welding, and 16 is low hydrogen direct current.

- Q: When welding electrode, how to move the electrode, can you point it in detail?

- What is the welding rod welding electrode Nie - composite motion: 1, which the feed movement of butt welding electrode2, the electrode moves along the center of the weld3, the repeated movement of the welding rod on the transverse direction of the weld or other ways of moving the strip

- Q: How to calculate the amount of electrode used in pipe welding?

- The number of welds can be multiplied by the amount of each opening. The dosage of the cut can be calculated by the quota method or the volume method. Generally, a ton of steel has an average number of electrodes.Carbon steel, stainless steel or alloy steel products are joined together with other products by welding electrodes when they are in production or construction. The seam of the welding rod between the product and the product is called the welding seam. Also called weld seam.

- Q: Which prawns can help give an answer, all kinds of stainless steel electrode guarantee period is how long, this has specific standards can be found? Thank youThe best hope for friends to answer, you can attach the standard name.

- Stainless steel welding rod shelf life, good preservation for two years, do not damp. Stainless steel electrode can be divided into chromium stainless steel electrode and chromium nickel stainless steel electrode, these two kinds of welding rod in accordance with national standards, according to the national standard GB/T983-1995 examination. Chromium stainless steel has certain corrosion resistance (oxidizing acid, organic acid, cavitation erosion), heat resistance and corrosion resistance. It is usually chosen as power station, chemical, petroleum and other equipment materials. But chromium stainless steel generally weldability is poor, should pay attention to welding process, heat treatment conditions and choose the appropriate welding rod. Chromium nickel stainless steel electrode has good corrosion resistance and oxidation resistance. It is widely used in chemical, chemical fertilizer, petroleum and medical machinery manufacturing. In order to prevent intergranular corrosion due to heating, the welding current should not be too large, less than 20% of the carbon steel electrode, the arc should not be too long, the inter layer is cold, and the narrow welding bead is suitable.

- Q: Why do welding electrodes need heating?

- The moisture in the skin of the drying agent prevents the welding from producing hydrogen pores when the water is heated.

Send your message to us

Welding Electrodes Factory Supply Directly E 6013 BS 639 E4322R21

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords