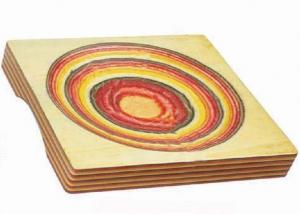

Removable White Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 Pieces watt

- Supply Capability:

- 100 Pieces per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Swing Board :

The area you can write on Swing Board is 1.5 times when compared with the conventional white board.

1. The area you can write on Swing Board is 1.5 times when compared with the conventional white board.

2. You can write and draw on the 6 pages of Swing Board.

3. The revolution of the panels (front - back) is quick and smooth.

4. The letters written on the surfaces of Swing Board do not turn upside down because the panels revolve horizontally.

5. You can use it at the arbitrary angles from 0 to straight angle.

6. You can use it at the corner part of the chamber when Swing Board is opened at 90 angle.

7. Swing Board is foldaway, so it can be set compactly.

8. Swing Board is easy to carry.

9. Product size (mm)

1). When opened in maximum : 1800w x 1800h

2). When closed : 900w x 1800h

3). Board size : 900w x 900h

10. Attachments : 2 marker pens (red, black), 1 eraser, 6 magnets.

Price : USD $1850 / 1product

The price is our recommended user price in Japan.

- Q: What kind of welding rod used for HRB500 steel bars?

- What kind of welding rod used for HRB500 steel bars?Answer: if there is no design requirements, according to the electric arc welding joint form, please refer to "JGJ18-2012" Specification for welding and acceptance of article 3.0.3 of the:

- Q: One millimeter thick iron direct current welding machine welding 3.2 electrode, need much current?

- 1, 3.2 electrode obviously thicker; should use less than 2.5 diameter of small welding rod;2 、 welding electrode and current matching empirical parametersWelding rod diameter 1.6, 2, 2.5, 3.2, 4, 5, 5.8Current (A) ranged from 25~4040 to 6050~80100 to 130160~210200 to 270260~300This is the experience of welding current, welding, horizontal welding, overhead welding welding current should be smaller than usual 10% ~ 20%.Exp is the confirmation at the time of the experiment. Therefore, before the formal welding, the welding sample should be taken, and the welding current should be obtained to get a solid and beautiful bead.

- Q: 400A DC inverter welding machine, suitable for long welding electrode

- Mainly depends on your welding machine load rate of 45%, then the current is about 180A, 60% of the current is about 240A, with experience that is 3.2

- Q: What brand of welding rod or welding wire for Q345B material?

- Q345 steel is made of E50 type electrode (GB-T5118). For low strength steel and high strength steel, welding rod should be used to match low strength steel.The welding wire is not 506. This brand is ER50-6 copper plated solid welding wire.The tensile strength of the welding wire belongs to the E50 series, and the strength of the electrode with E5003 E5015 E5016 has been constant.Q345B belongs to low alloy steel. Aka: 16Mn.ER50-6 wire, coinciding with Q345 (B) strength, has been. You can use it safely.The tensile strength of ER50-6 welds is higher than that of E5015 E5016 welding electrodes. Solid two seam welding with minimum hydrogen content.

- Q: Can ordinary 422 electrode welding pig iron?

- No welding, it will crack, like the 2012 blockbuster film in the same terrible crack.

- Q: Mainly the advantages and disadvantages of J502 welding rod performance, as well as the development status at home and abroad,

- Titanium calcium electrode belongs to J422 (E4303). It has good process, stable arc, beautiful welding seam, but low impact toughness and strength. It is not suitable for welding with high structural performance requirement.J507 low hydrogen type basic welding rod, basically contrary to J422. The process is bad, the arc is unstable, only the direct reverse welding and short arc welding can be used. However, because of the strong hydrogen removal ability, hydrogen cracking and defects are not produced, and the impact toughness is high, which is suitable for welding with high structural performance requirements.

- Q: What is the J422 electrode core material

- The J421Z electrode is composed of two parts, core and coating composition. The electrode is coating in metal welding core (coating), uniform centripetal pressure applied to core.The electrode of different types, different cores. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal. The core components directly affect the composition and properties of the weld metal, so the harmful elements in the welding core to as little as possible. For welding of carbon steel and low alloy steel welding core, are mostly made of low carbon steel as the core, and adding manganese, silicon, chromium, nickel and other components (see wire national standard GB1300 - 77). The reason of low carbon is a low carbon steel wire plastic, wire drawing is relatively easy, on the other hand can reduce the CO content of reducing gas, reduce spatter or porosity and increased weld metal solidification temperature, favorable for overhead welding. The addition of other alloy elements mainly guarantees the comprehensive mechanical properties of the weld, and also has some effect on the welding process performance and the removal of impurities.

- Q: Hand welding electrodes 3.2 and 4 which are more commonly used?

- Electrode core diameter, that is to say, 3.2 of the electrode core is 3.2 millimeters in diameter, and 4 is 4 millimeters in diameter.The diameter of the welding rod is large, and the current should be larger when welding. High current, high efficiency, can be used in relatively thick plate welding. On the contrary, relatively thin plate welding, should choose a smaller diameter welding rod.Electrodes commonly used in three specifications, 3.2, 4, 5. Civil J422 and J506 more commonly used, industrial use of J507, J427 more. But the civilian use of 3.2 diameter more.

- Q: What kind of welding rod should be used for welding cast iron? 506?

- With 506 is OK, with gas welding is also possible.

- Q: What is bubble welding? What's the difference between a common electrode and an ordinary one?

- Now, there are still two people suspected of welding costs?Do not know that science and technology is the primary productive force?!Said the first two welding material, welding wire electrode 8 dollars a kilogram, 6 yuan a kilo, looks cheap electrode.You have to see how much of the filler metal left in the weld after welding is equal to the price.1, the outside of the electrode coating, and finally the welding slag and protective gas, does not belong to the filler metal.2, each electrode has a welding rod head, at least 5 centimeters, have to throw away, does not belong to the filler metal.3, welding rod splash, splash of metal, does not belong to the filler metal.In addition, other costs, welding rod to dry, need oven, heat preservation barrel, heating electricity, throw away the welding rod.Let's talk about the same welding power, welding, welding heat input two is small, costs less power, more power inverter welder.What's more about efficiency and speed?.1, do not bake electrode, save time, minus a manual.2, do not change electrode, also need not from new arc, save time3, do not knock the welding slag off at least a coolie.4, for welding speed, two welding is three times of welding rod. (on this one, a welder can top three, you have to calculate how much money, artificial!)

1. Manufacturer Overview

| Location | |

| Year Established | 1947 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Removable White Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 Pieces watt

- Supply Capability:

- 100 Pieces per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords