Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Welding Rod Description:

E6010 This electrode is used for all position welding using DCRP.

produces a deep penetrating weld and works well on dirty,rusted, or painted metals

E6011 This electrode has the same characteristics of the E6010, but can be used with AC and DC currents.

E6013 This electrode can be used with AC and DC currents.

produces a medium penetrating weld with a superior weld bead appearance.

E7018 This electrode is known as a low hydrogen electrode and can be used with AC or DC.

The coating on the electrode has a low moisture content that reduces the introduction of hydrogen into the weld. lectrode can produce welds of ray quality with medium penetration.

(Note, this electrode must be kept dry. If it gets wet, it must be dried in a rod oven before use.)

2.Main Features of Welding Rod:

1): Durable, strict quality management and control.

2): High precision machining equipments guarantee good quality.

3): Smooth surface. No defects. Continuous skill improvements.

4): Quick delivery, competitive Chinese price. Low MOQ.

5): Our Company is specialized in machining service on precise mechanical parts; we are producing high precision parts for military enterprise

6): We have design team to develop new skill and new products to meet requirements of markets.

7): Good service, when customers have problems during use, we will surely try our best to solve them.

8): High professional employees have good emergency-dealing ability during production.

9): Surface treatment can be nickel, galvanized and painted, or based on the requirements of customers.

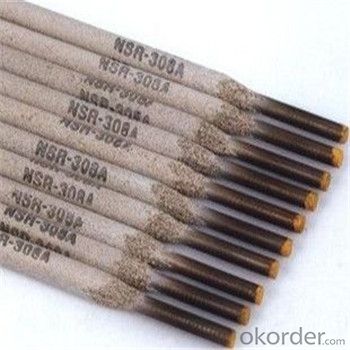

3. Welding Rod Images

4. Welding Rod Specification

Chemical Composition | C | Mn | Si | S | P |

Guarantee Value | ≤0.12 | 0.3-0.6 | ≤0.35 | ≤0.035 | ≤0.040 |

Mechanical Properties of Deposited Metal

Test Item | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) | KV2(J) |

Guarantee Value | ≥420 | ≥330 | ≥17 | -(normal temperature) | -(0℃) |

Reference Current (AC, DC)

Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

Length(mm) | 300 | 300(350) | 350 | 400 | 400 |

Welding Current (A) | 40~70 | 55~95 | 80~130 | 120~180 | 160~230 |

V-up, OH | 35~60 | 45~90 | 60~120 | 100~160 | 120~200 |

5.FAQ

Q: How do you ship the Welding Rod?

A: Usually by sea.

Q: Are you a manufacturer?

A: Yes, we have been in providing the professional products in Welding Rod over 10 years.

Q: Can I get the sample?

A: Yes, free samples are prepared for your test.

- Q: What type of welding rod is used for welding 16MnD?

- Using J507RH welding rod.DC reverse connection.Preheat about 100 degrees before welding.When the plate thickness is less than or equal to 20mm, the V type groove is opened and the U groove is used when the plate thickness is greater than 20mm.Current: Phi 3,2 welding rod A=130-150, Phi 4 electrode A=180-200, Phi 5 electrode A=230-250.Conditional, should be done after welding stress treatment.

- Q: What wire and electrode are used for the welding of 0Cr18Ni10Ti stainless steel pipes? Thank you

- 1, 0Cr18Ni10Ti stainless steel pipe welding using H0Cr20Ni10Ti welding wire, welding rod using A132 or A137.2, if welding with electrodes, I suggest the use of A137 welding, because of its crack resistance performance than A132 much better.

- Q: When 507560 electrodes are used at the same time, which electrode should be selected?

- 507 506 welding preferred 506. No 560 electrodes, this specification, model, brand.Brand: J506, model: E5016 belongs to low hydrogen and potassium alloy structural steel welding rod. AC welder (no-load voltage is not lower than 70V, machine load rate of not less than 60% of rated output current, welding welding not less than 300 Amperes) DC welder (reverse connection wire clamp is connected with the cathode electrode holder is connected with the anode -, +) polarity electrode. Good welding process. Non Q345 class boilers, containers, pipes and other special components; first choice should be J506 welding rod.Brand: J507, model: E5015 belongs to low hydrogen sodium type low alloy structural steel welding rod. The electrode does not contain arc stabilizer. Only reverse polarity welding shall be used. Suitable for welding Q345R, container, steel and other precision parts. Compared with J506, the deposited metal has lower porosity, slag inclusion, crack and so on. It shall not be used without DC welder.

- Q: Can ordinary electrode be used for welding cast iron?

- No way! Cast iron electrodes must be used! Ordinary welding rod welding porosity is too much, not solid.

- Q: Is the electrode electrically conductive?

- Because there is wire electrode conductive, synthesis of various substances, covered up, welding machine output two AC machine is not divided into wire, welding wire, welding machine DC cathode to anode grounding wire, two output voltage will be encountered after the ignition, the electrode is electrically conductive. The electrode was encountered after the ignition, melting body, outside of the medicine is to protect the melted wire, prevent the pores, electrode head with no welding electrode holder, if the flux is not conductive to clip, also cannot be welded

- Q: What kind of welding rod is used for welding rail and ordinary steel?

- With J506 electrode, but only in welding before welding on 60 degrees of groove; after welding, welding parts with dry lime insulation until the weldment in the lime natural cooling.

- Q: Why should the electrode be dry?

- Some of the electrode coating will absorb moisture, the skin will contain moisture in the welding process, water will be decomposed into hydrogen overflow, part of it will stay in the weld to form hydrogen pores.

- Q: 302 which kind of electrode should be used for welding stainless steel with iron?

- 302 stainless steel watch to cast iron or wrought iron welding.If with iron welding, WE777 welding rod can be used for iron and stainless steel welding, cold welding welding processIf it can be used for wrought iron, steel, including stainless steel and carbon steel, alloy steel and alloy electrode WE600 dissimilar steel welding.

- Q: Why should the electrode be baked before use?

- I don't want to tell you anything that is very theoretical and very textbook. Our project is very wet in the south, so the steel production base often does.The main reason for baking the electrode is (or to prevent) the welding rod from being wetted.Welding rod after wetting, in the welding of workers will indirectly cause more slag, more bubbles, the current is not good control, burn the main tendons, and the strength of the steel bar connection will not meet the design requirements.That's all.

Send your message to us

Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords