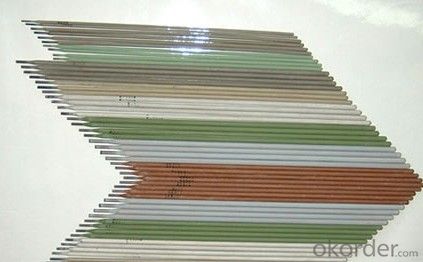

ER 308 stainless steel welding welded wire bare stick rod TIG

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1) Grade:ER304, ER304L, ER307, ER307Si, ER308, ER308L, ER308LSi, ER310, ER316, ER316L, ER316LSi, ER347, ER347Si, ER309, ER309L, ER430, ER420, etc

2) Standard: GB, SUS, AWS, JIS, DIN, BS970

3) Diameter: 0.6-5.0mm

4) Packing: in coil, bundle or spool, then in carton or as your request

300kg/spool 25kg/spool 20kg/spool 15kg/spool 5kg/spool 12.5kg/spool 1kg/spool

Tig argon arc welding wire packing in drums 1m/line 5Kg/drum 10kg/drum

5) Application: MIG, TIG, and submerged arc wires for welding a wide variety of stainless steels

Chemical Composition:

| Chemical Composition Requirements | AWS A5.9/A5.9M:2006 | ||||||||||

| AWS Classificationd | UNS Numberf | C | Cr | Ni | Mo | Mn | Si | P | S | N | Cu |

| ER209 | S20980 | 0.05 | 20.5–24.0 | 9.5–12.0 | 1.5–3.0 | 4.0–7.0 | 0.90 | 0.03 | 0.03 | 0.10–0.30 | 0.75 |

| ER218 | S21880 | 0.10 | 16.0–18.0 | 8.0–9.0 | 0.75 | 7.0–9.0 | 3.5–4.5 | 0.03 | 0.03 | 0.08–0.18 | 0.75 |

| ER219 | S21980 | 0.05 | 19.0–21.5 | 5.5–7.0 | 0.75 | 8.0–10.0 | 1.00 | 0.03 | 0.03 | 0.10–0.30 | 0.75 |

| ER240 | S24080 | 0.05 | 17.0–19.0 | 4.0–6.0 | 0.75 | 10.5–13.5 | 1.00 | 0.03 | 0.03 | 0.10–0.30 | 0.75 |

| ER307 | S30780 | 0.04–0.14 | 19.5–22.0 | 8.0–10.7 | 0.5–1.5 | 3.30–4.75 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER308 | S30880 | 0.08 | 19.5–22.0 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER308Si | S30881 | 0.08 | 19.5–22.0 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER308H | S30880 | 0.04–0.08 | 19.5–22.0 | 9.0–11.0 | 0.50 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER308L | S30883 | 0.03 | 19.5–22.0 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER308LSi | S30888 | 0.03 | 19.5–22.0 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER308Mo | S30882 | 0.08 | 18.0–21.0 | 9.0–12.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER308LMo | S30886 | 0.04 | 18.0–21.0 | 9.0–12.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER309 | S30980 | 0.12 | 23.0–25.0 | 12.0–14.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER309Si | S30981 | 0.12 | 23.0–25.0 | 12.0–14.0 | 0.75 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER309L | S30983 | 0.03 | 23.0–25.0 | 12.0–14.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER309LSi | S30988 | 0.03 | 23.0–25.0 | 12.0–14.0 | 0.75 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER309Mo | S30982 | 0.12 | 23.0–25.0 | 12.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER309LMo | S30986 | 0.03 | 23.0–25.0 | 12.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER310 | S31080 | 0.08–0.15 | 25.0–28.0 | 20.0–22.5 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER312 | S31380 | 0.15 | 28.0–32.0 | 8.0–10.5 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER316 | S31680 | 0.08 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER316Si | S31681 | 0.08 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER316H | S31680 | 0.04–0.08 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER316L | S31683 | 0.03 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER316LSi | S31688 | 0.03 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER316LMn | S31682 | 0.03 | 19.0–22.0 | 15.0–18.0 | 2.5–3.5 | 5.0–9.0 | 0.30–0.65 | 0.03 | 0.03 | 0.10–0.20 | 0.75 |

| ER317 | S31780 | 0.08 | 18.5–20.5 | 13.0–15.0 | 3.0–4.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER317L | S31783 | 0.03 | 18.5–20.5 | 13.0–15.0 | 3.0–4.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER318 | S31980 | 0.08 | 18.0–20.0 | 11.0–14.0 | 2.0–3.0 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER320 | N08021 | 0.07 | 19.0–21.0 | 32.0–36.0 | 2.0–3.0 | 2.5 | 0.60 | 0.03 | 0.03 | — | 3.0–4.0 |

| ER320LR | N08022 | 0.025 | 19.0–21.0 | 32.0–36.0 | 2.0–3.0 | 1.5–2.0 | 0.15 | 0.015 | 0.02 | — | 3.0–4.0 |

| ER321 | S32180 | 0.08 | 18.5–20.5 | 9.0–10.5 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER330 | N08331 | 0.18–0.25 | 15.0–17.0 | 34.0–37.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER347 | S34780 | 0.08 | 19.0–21.5 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER347Si | S34788 | 0.08 | 19.0–21.5 | 9.0–11.0 | 0.75 | 1.0–2.5 | 0.65–1.00 | 0.03 | 0.03 | — | 0.75 |

| ER383 | N08028 | 0.025 | 26.5–28.5 | 30.0–33.0 | 3.2–4.2 | 1.0–2.5 | 0.5 | 0.02 | 0.03 | — | 0.70–1.50 |

| ER385 | N08904 | 0.025 | 19.5–21.5 | 24.0–26.0 | 4.2–5.2 | 1.0–2.5 | 0.5 | 0.02 | 0.03 | — | 1.2–2.0 |

| ER409 | S40900 | 0.08 | 10.5–13.5 | 0.6 | 0.5 | 0.8 | 0.8 | 0.03 | 0.03 | — | 0.75 |

| ER409Nbi | S40940 | 0.08 | 10.5–13.5 | 0.6 | 0.5 | 0.8 | 1 | 0.04 | 0.03 | — | 0.75 |

| ER410 | S41080 | 0.12 | 11.5–13.5 | 0.6 | 0.75 | 0.6 | 0.5 | 0.03 | 0.03 | — | 0.75 |

| ER410NiMo | S41086 | 0.06 | 11.0–12.5 | 4.0–5.0 | 0.4–0.7 | 0.6 | 0.5 | 0.03 | 0.03 | — | 0.75 |

| ER420 | S42080 | 0.25–0.40 | 12.0–14.0 | 0.6 | 0.75 | 0.6 | 0.5 | 0.03 | 0.03 | — | 0.75 |

| ER430 | S43080 | 0.10 | 15.5–17.0 | 0.6 | 0.75 | 0.6 | 0.5 | 0.03 | 0.03 | — | 0.75 |

| ER439 | S43035 | 0.04 | 17.0–19.0 | 0.6 | 0.5 | 0.8 | 0.8 | 0.03 | 0.03 | –– | 0.75 |

| ER446LMo | S44687 | 0.015 | 25.0–27.5 | g | 0.75–1.50 | 0.4 | 0.4 | 0.02 | 0.02 | 0.015 | g |

| ER630 | S17480 | 0.05 | 16.00–16.75 | 4.5–5.0 | 0.75 | 0.25–0.75 | 0.75 | 0.03 | 0.03 | — | 3.25–4.00 |

| ER19–10H | S30480 | 0.04–0.08 | 18.5–20.0 | 9.0–11.0 | 0.25 | 1.0–2.0 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER16–8–2 | S16880 | 0.10 | 14.5–16.5 | 7.5–9.5 | 1.0–2.0 | 1.0–2.0 | 0.30–0.65 | 0.03 | 0.03 | — | 0.75 |

| ER2209 | S39209 | 0.03 | 21.5–23.5 | 7.5–9.5 | 2.5–3.5 | 0.50–2.00 | 0.90 | 0.03 | 0.03 | 0.08–0.20 | 0.75 |

| ER2553 | S39553 | 0.04 | 24.0–27.0 | 4.5–6.5 | 2.9–3.9 | 1.5 | 1.0 | 0.04 | 0.03 | 0.10–0.25 | 1.5–2.5 |

| ER2594 | S32750 | 0.03 | 24.0–27.0 | 8.0–10.5 | 2.5–4.5 | 2.5 | 1.0 | 0.03 | 0.02 | 0.20–0.30 | 1.5 |

| ER33–31 | R20033 | 0.015 | 31.0–35.0 | 30.0–33.0 | 0.5–2.0 | 2.00 | 0.50 | 0.02 | 0.01 | 0.35–0.60 | 0.3–1.2 |

| ER3556 | R30556 | 0.05–0.15 | 21.0–23.0 | 19.0–22.5 | 2.5–4.0 | 0.50–2.00 | 0.20–0.80 | 0.04 | 0.015 | 0.10–0.30 | — |

- Q: Air conditioning copper pipe welding problems, how to weld well, and what electrode to use?

- Is the use of copper wire, welding, brazing is the longest, with the copper wire, with borax flux do. The gas heating tube to cherry red, under the solder wire, a coating will flow into, good welding.

- Q: Electric welding machine welding, welding rod old stick metal, welding rod burning red, very scary

- 1, this is because you are novice unskilled operation caused,2, teach you two kinds of arc welding method:1) scratch: this method is easier to control, but it is easy to damage the surface of weldment. The welding rod shall be aligned with the weldment at first, then the electrode will be lightly scratched on the surface of the weldment as a match. The arc will be ignited, and then the electrode will be improved by about 2-4mm, and it will be stably ignited.2) direct method: the end of the electrode aligned welding parts, and then bend the wrist, so that the electrode slightly touched the weldment, and then quickly put the electrode about 2-4mm, arc ignition, wrist flat, so that the arc to maintain stable combustion. The method does not scratch the surface of the weldment and is not limited by the size and shape of the weldment surface, so it is widely used in production. But this method is not easy to master, the welder must have higher proficiency in operation.3) starting welding: after the arc is ignited, the arc will be lengthened a little longer, the butt welding parts should be preheated as necessary and appropriate, then the arc should be pressed properly and transferred to the normal welding procedure.3, usually practice more, do not worry, I believe you will succeed.

- Q: Where to buy electrodes, how to buy online, welding rod is always not assured

- Mechanical and electrical market to buy it, each region has the corresponding welding rod manufacturer's general sales agent, go to the market to buy it, our company has a procurement, is to buy Wire online, and then cheated, pay attention to good.

- Q: Don't long winded, concise, thank you!

- The common electrode: in the welding process, it is also the weld metal fill electrode, its edge welding edge melting, and to fill in the weld.Tungsten electrodes: non melting electrodes for manual argon arc welding. Or plasma melting non melting electrodes.

- Q: Welding rod heat preservation barrel should be clamped in the welding machine

- The wire end can be used with the insertion of the electrode insulation barrel insulation barrel, the other end two clips are respectively clamped in a quick connector holder, on the ground. The above is nonsense, since you ask, I estimate you are far away from the welding operation machine, can not be used with a wire insulation barrel. There are two solutions: 1. the insulation barrel comes with wire clip extension cord is cut off; 2. comes with a wire end clamp bare wire in wire, welding tongs plastic handle truncated, the wire clip in the wire holder. In short, to form the current loop can be.

- Q: What welding rod steel

- They are malleable iron:The form of carbon: the presence of a group of flocculent graphite (white iron is heated to 930 degrees, cooled slowly and annealed for a long time)Features: it has higher tensile strength and better plasticity, but it can not be forged. It is necessary to cast thin-walled parts with complex shape and impact load. Such as: wheel hub, brake, crankshaft, camshaft, connecting rod, piston ring, universal jointWelding electrode:Copper iron cast iron electrode (Z607, Z612) high vanadium electrode (Z116, Z117) oxidation of cast iron electrode (Z110) sometimes ordinary low carbon steel electrode such as E4315 (J427), E5015 (J507) after welding processing: pure nickel EZNi-1 (Z308), EZNiFe (Z408), nickel (nickel and copper EZNiCu Z508).

- Q: How do you make holes in the steel plate with the welding rod?

- 1, the following general 10MM board directly to the plate electrode for an empty blow through, must further expand air through the air, need more air electrode with air to air around the suitable size, but the steel bottom board should be suspended, is conducive to the burning capacity of molten iron flow, general space only with electrode blowing, too small to empty is not blowing to using electric drill.2, the electrode (coveredelectrode), is the metal coating in the welding core (coating), uniform centripetal pressure applied to core. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal. The electrode consists of two cores and coating composition. The different cores are also different. The core components directly affect the composition and properties of the weld metal, so the harmful elements in the welding core to as little as possible.

- Q: Why is the welding of important structure using alkaline electrode?

- Alkaline is a low hydrogen electrode, which can control the hydrogen content in the weld, avoid hydrogen embrittlement and lead to structural failure. Hydrogen embrittlement is the sudden breaking of the weld force

- Q: What brand of carbon steel electrode is the best?

- Ordinary carbon steel electrodes are similar, the strength requirements are not very high, the welding rod does not have the best, all in line with national standards, but to see the welding technology is good.

- Q: What's the model of lap welding for two grade steel bars?

- You should first look at what is the project of the Ministry of communications and the Ministry of water resources, the other I know better, the Ministry of construction and the Ministry of Railways is not clear, each industry standard is not the same, so you have to figure out is what industry.If it is the Ministry of communications project, two steel bar can use E43 electrode, but the Ministry of water resources can not, need to use E50. These are found on the corresponding construction codes for reinforced concrete

Send your message to us

ER 308 stainless steel welding welded wire bare stick rod TIG

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords