Waxing Polishing Machine M17

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 500 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Waxing Polishing Machine M17

1. 2.0HP power

2. Wax removal

3. Polishing of cement floor

4. Floor scrubber

Hard Floor Scrubbing, Stripping, Buffing, Spraying Cleaning, Carpet Shampooing, Waxing Polishing Machine M17H

swing buffer machine comes with everything you need to strip and refinish a waxed and finished hard floor: scrubbing, stripping, buffing, spray cleaning, and extends carpet shampooing due to equipped with Dry-Powered shampoo brushes.

Usages of Waxing Polishing Machine M17

Wax removal

Deep or maintenance cleaning

Dry & damp carpet cleaning

Polishing of cement floor foundries

Features of Waxing Polishing Machine M17

Ergonomic design, all controls in hand, adjustable handle height and smooth operation

Reinforced HDPE structure with a mineral fibre resists to acids and alkaline

Advantages of Waxing Polishing Machine M17

Poly functional machine

Superior gloss great cleaning performance

Quick operation, highly controlled water discharge, quick drying & short traffic interruption during damp carpet cleaning

Highly noiseless machine for full range of environments, as hotel, restaurant, office, school, hospital

Accessories of Waxing Polishing Machine M17

Water tank, Pad driver, Floor brush, Carpet shampoo brush

Technical data of Waxing Polishing Machine M17

M17H | |

Voltage | 220V |

Power | 2.0HP |

Rotate Speed | 150RPM |

Stripping Pad Diameter | 17" |

Weight | 52KG |

Power Cord Length | 12M |

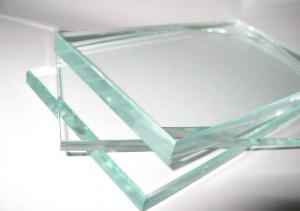

- Q: What is the raw material of glass products?

- Ordinary glass raw materials are soda ash (sodium carbonate), limestone (calcium carbonate) and silica, after a high temperature reaction, the products are mainly sodium silicate, calcium silicate and silica

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- According to the degree of finish is divided into yaguangyoumianzhuan and light glazed tiles. At present, the ground material with more matte glazed tiles.The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series). Vitreous tile belongs to all ceramic product. Its abrasion resistance and flexural strength are very high, the water absorption rate (tile water absorption rate is less than 1 per thousand). Before the tiles mainly used for flooring, tiles, as a wall material is mainly used for high-grade Gaestgiveriet Hotel, office space, but now, with the living standard and the improvement of consumption level, the home use tiles for the kitchen wall materials are more and more family.

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- The elemental substance of fluorine is F2, which is a pale yellow [1], highly poisonous gas. Fluorine gas corrosion is very strong, very active chemical properties, is one of the most oxidizing substances, and even some inert gases can react under certain conditions [2]. Fluoride is a special plastic, rubber and freezers (freon-12) key elements in. Because of the special chemical properties of fluorine, fluorine chemistry plays an important role in the development of chemistry.

- Q: The benefits of natural thin wood planks

- Sheet material means a flat rectangular building material plate with a width of more than 2 times its thickness, usually made of flat rectangular building material, used as a wall, ceiling, or floor member. Also refers to the forging, rolling or casting of the metal plate, divided into thin plate, medium plate, thick plate, thick plate, usually made of standard size flat rectangular building material board.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Environmental protection standards, with the domestic high-end glass development needs, coconut shell materials are gradually replaced by its excellent performance after falling green traditionChemical mildew proof isolating material.Applicability: (1) glass against mildew; II. Glass anti scratch;Other special applicability:Solid desiccant; plant cultivation raw material, animal feed, etc.; colloid filling material; catalyst carrier; impurity and harmful gas dispel;

- Q: The difference between glass wool, rock wool, mineral wool

- Glass wool belongs to a kind of glass fiber, it is a kind of man-made inorganic fiber. Glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: What kind of material is made of automobile glass?

- Ordinary glass breaks can be irregular chunks

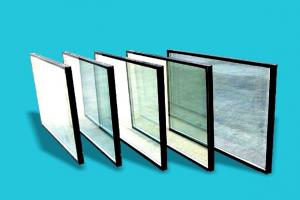

- Q: How to identify and select high quality insulating glass?

- The raw materials of the latter two kinds of insulating glass are glass, aluminium strip, insert angle, butyl glue, double component polysulfide glue or silicone rubber, drying agent and compound sealant.Jieyang Hongguang glass is a special glass, customer service very detailed answer.

- Q: What kind of raw material does glass form? What is the general smelting process?

- It is a kind of quartz sand ore like ore, of course, a variety of quartz ore

- Q: What kind of film is toughened glass film?

- PP materialPP protective film material is first appeared in the market, the chemical name is polypropylene, no adsorption capacity, generally use glue to stick, tear after the glue will leave marks on the screen, the screen for a long time will be corrosion. This material has been basically eliminated by the vast number of protective membrane manufacturers, but some roadside stalls are still selling, we should pay attention to!

1. Manufacturer Overview

| Location | Anhui,China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered . |

| Product Price Range | |

Send your message to us

Waxing Polishing Machine M17

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 500 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords