Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1. Specifications for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1).Strength: 20x20kn/m--600x600kn/m, such as :60/30, 60/60, 80/30, 120/30, 150/30, 200/30 etc.

2).Polyester Geogrid coated with PVC, Bitumen, SBR

3).Elongation:10% and 13%

4).Width: 1--6m

5).Packing:50m or100m/roll,

6).PE film outside, plstic tube inside.also can be made according clinet's need.

2. Application for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1)Roadbed reinforcement of road and railway, crack prevention, increase of roadbed strength;

2)Reinforcement and stabilization of riverside, embankment and side slope;

3)Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increase of stability and loading capacity of fundus;

4)Reinforcement of the surface of road and bridge

3. Technical Data for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | |

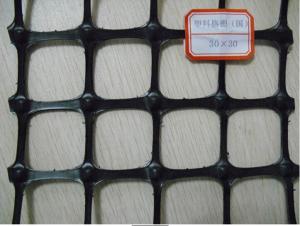

4. Some Photos for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

- Q:Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids are a type of geosynthetic material that can provide structural stability and improve the overall strength of embankments. They are commonly used to distribute loads, reduce lateral spreading, and prevent soil erosion. When used in conjunction with proper engineering techniques, geogrids can effectively reinforce embankments on collapsible soils and mitigate potential issues related to soil collapse.

- Q:Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids are commonly used in retaining walls to enhance stability and improve the overall performance of the structure. They provide reinforcement and prevent soil erosion, which is crucial for the durability and longevity of residential retaining walls.

- Q:How do geogrids enhance the stability of railway track embankments?

- Geogrids enhance the stability of railway track embankments by providing additional reinforcement and preventing soil erosion. They improve load distribution, increase bearing capacity, and reduce settlement, ultimately ensuring the long-term stability of the embankment.

- Q:How much is a glass fiber mesh

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, high tensile strength, elasticity, tensile strength and elongation between alkali resistant glass fiber mesh elastic limit, so the glass fiber mesh cloth price range is large, with "Jining wellav" WL-0812 series products the price, floating in the price range of $0.32--5

- Q:How do geogrids improve the performance of geosynthetic encased columns?

- Geogrids improve the performance of geosynthetic encased columns by enhancing their load-bearing capacity, increasing their stability, and reducing settlement. Geogrids act as reinforcing elements within the column, distributing the applied loads more efficiently and preventing lateral spreading. This reinforcement enhances the overall strength and stiffness of the column, enabling it to support heavier loads and resist deformation, settling, and lateral movement. Additionally, geogrids improve the long-term performance of the columns by reducing the potential for differential settlement, ensuring more uniform load distribution, and increasing the overall durability and longevity of the structure.

- Q:How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They distribute the applied loads more evenly, reduce soil movement and prevent the occurrence of sliding or failure. Additionally, geogrids increase the bearing capacity of the soil, enhance drainage, and improve overall durability and longevity of the retaining structures.

- Q:Can geogrids be used in floating parking lot construction?

- Yes, geogrids can be used in floating parking lot construction. Geogrids are commonly used in various civil engineering applications, including building parking lots. They help reinforce the ground and distribute loads, making them ideal for stabilizing the soil beneath floating parking lots.

- Q:Do geogrids provide reinforcement to geosynthetic clay liners in landfill caps?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in landfill caps. Geogrids are often used in combination with geosynthetic clay liners to enhance their tensile strength and overall stability. The geogrids help distribute loads and prevent excessive deformation, improving the performance and longevity of the landfill caps.

- Q:Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are high-strength, durable materials that can effectively stabilize and reinforce soil or rock structures. They can be used to create stable walls, slopes, or liners in tailings containment areas, helping to prevent erosion, control flow, and enhance the overall stability of the containment system.

- Q:What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes. These factors include the type and stability of the soil, the slope angle and height, the expected loads and stresses, the environmental conditions, and the required design life of the reinforcement system. The geogrid material and its strength, stiffness, and durability characteristics are also important considerations. Additionally, factors such as installation methods, cost, and availability of geogrids may influence the design and selection process. Overall, a thorough understanding of the site conditions and project requirements is essential in order to choose the most appropriate geogrid for slope reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords