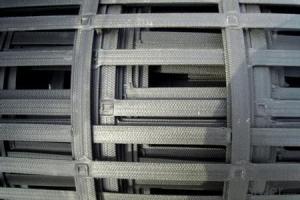

Woven Polyester Geogrids - Embellish Two-Way Plastic Geogrid Products Forever

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass grille

Fiberglass grille

Products overview:

Shandong yongrun glass fiber grating is using high quality enhanced non-alkali glass fiber yarn, using foreign advanced the warp knitting woven into base material, USES the warp knitting oriented structure, make full use of fabric, yarn strength improve its mechanical properties, make its have good tensile strength, tensile strength and resistance to creep properties, and through high quality modified drain green coating processing and into the plane of the network materials. Following the principle, key to highlight similar compatible with the composite performance of asphalt mixture, and full protection of the glass fiber base material, greatly improves a base material wear resistance and shearing ability, so as to be used for road, crack resistance and enhance rut highway diseases occurring, the end of the asphalt pavement is difficult to enhance of difficult problems. Product features: The product has high strength, low extension, high temperature resistant, high modulus, light weight, good toughness, corrosion resistance, long life and other characteristics, which can be widely used in the old cement road surface, airport runway repair, DAMS, the bank slope protection, enhance bridge road engineering, can deal with to pavement enhancement, reinforcing, prevent pavement rut fatigue crack, hot cold crack and the following reflection adjustable crack, and the load stress can be scattered, prolong the service life of road surface, high tensile strength low elongation ratio, no long-term creep, physical chemistry stability is good, good thermal stability, resist fatigue cracking, high temperature resistant rut, resistance to low temperature shrinkage, delay reduce reflection crack.

Product application:

1. The old asphalt concrete pavements, the reinforcement of asphalt surface, prevention and cure disease enhancement.

2. Cement concrete road surface reconstruction compound, restrain the plate surface contraction caused crack reflection.

3. Road to engineering, prevention and control of extension of old and new band and the uneven settlement and cause a crack.

4. Soft soil base reinforcement treatment, beneficial to the soft soil water chromatography, and effectively suppress the consolidation settlement, uniform stress distribution, enhance the overall strength of roadbed.

5. New roads and a half the shrinkage crack, produce steel reinforcement to prevent the crack reflection and strengthen basic caused cracks road.

Packing specification:

GSB30-30-GSB150-150

- Q: Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce road bases and improve their load-bearing capacity. They can effectively distribute the load and prevent the formation of ruts and potholes, making them suitable for temporary haul roads during construction projects.

- Q: Can geogrids be used in temporary erosion control applications?

- Yes, geogrids can be used in temporary erosion control applications. Geogrids are versatile and effective in stabilizing soil and preventing erosion, making them suitable for temporary erosion control measures such as construction sites, temporary access roads, and stockpile areas.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and manufacturer. However, most geogrids range in thickness from 0.5 to 3 millimeters.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are typically resistant to high temperatures. They are designed to withstand extreme weather conditions, including high temperatures, without significant degradation or loss of performance.

- Q: What is the market price of the geotechnical grid in 2017

- (1) the first accurate release of subgrade slope line, in order to ensure the roadbed width of each side of the widened 0.5m, soil drying good leveling by 25T after vibroll pressure two times, then 50T shock pressure of four times, how much is the uneven supply market price? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong local earthwork grid with artificial coordination.

- Q: GSL50 what is the meaning of Geogrid

- GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and increasing the tensile strength of the soil. They are placed within the soil to distribute the stress and prevent sliding or collapse, effectively stabilizing the slope and minimizing erosion.

- Q: What are the factors that affect the design of geogrid installations?

- There are several factors that can influence the design of geogrid installations. These include soil type and characteristics, slope stability, anticipated loads and traffic, climate and environmental conditions, project requirements and specifications, and available construction equipment and techniques. Each of these factors must be carefully considered to ensure the successful design and implementation of geogrid installations.

Send your message to us

Woven Polyester Geogrids - Embellish Two-Way Plastic Geogrid Products Forever

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords