Wafer Check Valve_Duo Check Valve-PN10/PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | bubble bag+ paper case+ wooden box, OR per custoers' requiremen |

| Delivery Detail: | 7days, 15days, 30 days, according to customers' requirement |

Specifications

1.wafer check valve

2. approved by CE and ISO9001

3. meet ANSI,DIN,BS,etc

4. manufacturer supply

5. OEM valve accept

wafer type ,Duo check valve

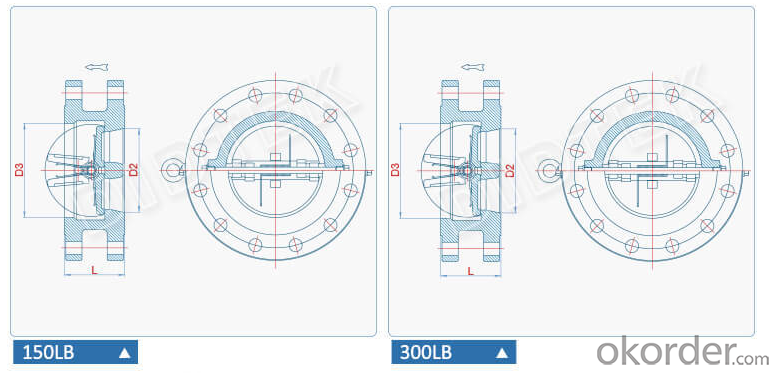

The standard of wafer type, duo check valve

1. Design standard conform to: MSS SP-67, API609, EN593

2. Connection flange conform to: DIN PN10/16/25, ANSI B16.1, BS4504, ISO PN10/16,

JIS B2212/2213, BS 10 Table D, BS 10 Table E

3.Top flange conform to: ISO 5211

4.Face to face conform to: API609, ISO5752 series 20, BS5155

5.Test standard conform to: API598

The design characters of wafer type duo check valve

Check valve is used for preventing the back flow of medium in pipelines and equipments. It will open and close automatically by the pressure of medium. When the medium is back-going, valve disc will close automatically to avoid accidents.

1. Tightly sealed, without leakage under the water pressure testing.

2. Economical, light weight, compact design-significantly lighter and less expensive than comparable swing check valves.

3. Easy to install and maintain.

The perfomance of wafer type, Duo check valve

1. Nominal Diameter: DN40-DN1200

2. Nominal Pressure PN (MPa): 1.0, 1.6, 2.0, 2.5

3. Testing pressure (water) Ps (MPa)

4. Body seat: 1.5 times rated pressure

5. Seat test: 1.1 times rated pressure

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the structure of the check valve of the screw air compressor?

- Work process: air pre filter, and then through the air filter and the air inlet controller into the mixing chamber and the compression screw lubricating oil, continuous linear by asymmetric rotor two, compression. The compressed oil and gas mixture enters the tank and the separation system for three levels of separation (centrifugal, self weight, and fine separation). The separated compressed air is discharged after the cooler is cooled, and a reliable pressure switch system controls the exhaust pressure. When the machine is running, the screw compressor run oil system by pressure difference automatic circulation, without pump. When starting, the minimum pressure valve is closed to ensure the minimum pressure required for the lubrication oil circulation. In addition to lubrication, the oil also acts as sealing, cooling and reducing noise. High efficiency oil and gas separator and high efficiency cooler ensure high quality compressed air.

- Q: The difference between swing check valve and lift check valve

- Swing check valve, swing check the valve to the disc valve seat around the channel axis for rotation, because the valve channel into a streamlined, flow resistance than the small valve lift check, suitable for large caliber occasions in low flow and no flow frequently change, but should not be used for the pulsating flow, the sealing performance is less than lift. Swing check valve is divided into single, double, and most types of three, the three forms mainly by the valve bore points, the purpose is to prevent the media to stop flow or reverse flow, weakening the hydraulic impact.

- Q: Can the check valves fit two in one tube? One up, the other down

- A water pipe is used for launching, and the two check valves that you install are reverse, and the water is blocked by one of the check valves on either side

- Q: What is the function of the check valve on the air compressor?

- Check valve is also called one-way valve, air will not go in only, can protect the air compressor host, if the air compressor main machine does not stop, you can not check valveIf it starts frequently, it must be loadedCheck valve bad consequences: motor overload, burn the host top off

- Q: The difference between the plunger type check valve and the lift check valve

- The two elastic seals are separated by a collar and secured to the sealing ring around the plunger by the load exerted by the valve cover nut on the valve cover. Elastic ring can be replaced, you can use a variety of materials, the valve is mainly used for "open" or "off", but with a special form of plunger or special ring can also be used to adjust flow.

- Q: How to use the check valve when the size of the pressure?

- 1) check valve: generally applicable to clean medium, should not be used for containing solid particles and viscosity medium.2), for the low pressure below DN50mm check valve, check valve should be selected on the clip, vertical lift check valve; for DN is greater than 200mm, less than 1200mm in the low pressure check valve, should use micro slow close check valve, water hammer eliminating buffer device with valve and check valve; for the low pressure DN is greater than 50mm, less than 2000mm should use check valve, butterfly valve and swing check valve.3), micro slow close check valve for easy to produce water hammer piping on the micro resistance slow closing system can well eliminate the media generated when the water hit counter, but limited by the temperature and pressure, generally used in low temperature pipe.4) for the closing of the water shock or small impact of the water pipeline, it is appropriate to use micro resistance slow closing check valve and buffer butterfly check valve.

- Q: The difference between slow closed valve and open the valve

- The difference is mainly that the opening and closing of the slow closing check valve depend on the external and external forces to perform the slow opening and closing (usually hydraulic cylinder or pneumatic cylinder). The swing check valve is opened and closed by the pressure of the pipe medium to complete the opening and closing (and the pressure of the pipeline).

- Q: What is the difference between the check valve and the check valve?

- The same thing is the flue check valve. We need to contact the manufacturer

- Q: Can the exhaust air outside the wall be fitted without a check valve?

- The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container mediumThe installation of check valves (Check, Valve) shall pay attention to the following items:A do not allow the check valve to bear weight in the line, and the large check valve shall be independently supported so as not to be affected by the pressure generated by the piping system.B, when installing, pay attention to the direction of the flow of medium should be in accordance with the direction of the body marked arrow.C and vertical vertical check valves shall be installed on the vertical pipe.D and lift type horizontal check valves shall be installed on horizontal pipes

- Q: Is it necessary to install a check valve in the piston refrigeration compressor?

- To solve this problem, we first need to know the working cycle of the piston compressor:1, compression process, suction valve closed, refrigerant gas in the cylinder from low pressure to high pressure process;2 the exhaust process, compression end, from the cylinder through the exhaust valve to exhaust pipe process;3, expansion process, exhaust end, exhaust valve closed, the piston from the bottom of the cylinder moving to the top of the cylinder process;4 suction process, suction valve opens, low-pressure refrigerant gas inhalation process of the cylinder;From the above piston engines don't seem to need what steps to open check valve. Because the suction valve and exhaust valve on the cylinder are constantly switching each other, the piston machine continues to inhale and exhaust the process. If only from the piston machine, there is no need to install a check valve.But to consider the whole refrigeration system, rather than a simple piston compressor, when the piston of more than 2 units must be horizontal pipeline in a single compressor exhaust pipe to the exhaust duct installed on the check valve and pipe installation is about

Send your message to us

Wafer Check Valve_Duo Check Valve-PN10/PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords