Vertical Tank Air Compressor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- N/A unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

All details for Vertical Tank Air Compressor:

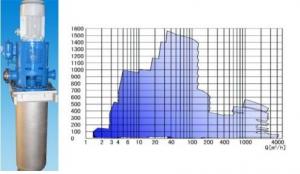

1, Production Introduction of Vertical Tank Air Compressor.

Series range of high pressure air cooled reciprocating air compressors are proven in Power generation, Oil & Gas, Carbon Fibre industries, emergency diesel engine starting, compressed air filling station, burst testing, hydraulic pressurizes chamber and fast growing population in PET blow moulding for food and beverage, pharmaceutical, and others modern industries applications

2, Specification of Vertical Tank Air Compressor.

| MODEL | V-0.25/8 | |

| Power | KW | 2.2 |

| HP | 3 | |

| Cylinder | mm | Φ65×2 |

| Rated speed | r/min | 1080 |

| Displace-ment | L/min | 250 |

| CFM | 8.8 | |

| Discharge pressure | Psi | 115 |

| bar | 8 | |

| Noises | dB(A) | 91 |

| Tank capacity | L | 190 |

| Usgal | 50 | |

| Net weight | kg | 111 |

| outer Size | (L×B×H)cm | 74×61×149 |

| MODEL | Z-0.20/8 | |

| Power | KW | 1.5 |

| HP | 2 | |

| Cylinder | mm | Φ55×2 |

| Rated speed | r/min | 1050 |

| Displace-ment | L/min | 200 |

| CFM | 7.1 | |

| Discharge pressure | Psi | 115 |

| bar | 8 | |

| Noises | dB(A) | 89 |

| Tank capacity | L | 115 |

| Usgal | 30 | |

| Net weight | kg | 111 |

| outer Size | (L×B×H)cm | 61×48×123 |

| MODEL | ZB-0.1/8 | |

| Power | KW | 1.5 |

| HP | 2 | |

| Cylinder | mm | Φ48×1 |

| Rated speed | r/min | 2850/3450 |

| Displace-ment | L/min | 206/248 |

| CFM | 7.3/8.8 | |

| Discharge pressure | Psi | 115 |

| bar | 8 | |

| Noises | dB(A) | 90 |

| Tank capacity | L | 76 |

| Usgal | 20 | |

| Net weight | kg | 42 |

| outer Size | (L×B×H)cm | 54×40×124 |

3, Package of Vertical Tank Air Compressor.

1) The standard exported package will be used if no special requirements.

2) The delivery date will be within 30 days.

4, Features of Vertical Tank Air Compressor.

1) Air compressors design are air cooled, multi-stage, base plate mounted units are available from 2.2Kw to 30Kw with discharge pressure up to 400 Bar .

2) High efficiency, high performance, energy saving, reliability and long life are the principle characteristics of piston air compressor.

3) The Free Air Delivery is from 0.15m3/min to 6.0m3/min.

4) Every machine is equipped with starting, unloading solenoid valve, auto condensate drain valve and advanced capacity control to make machine to operate safely and stably.

5) The quality can keep up with international standard as introduction of foreign technology.

- Q: How to judge compressor burn out?

- First of all, depends on whether the compressor will normally start, if not start the test compressor, there is no 220V, and then test starter protector, compressor start winding running coil winding is burned. If you can start normal, you see whether the amount of Freon is normal, open the process tube (fluorine tube) fluorine discharge, the pressure is large, that is, the compressor bad, inadequate exhaust.

- Q: What is the compressor blocking current?

- When the compressor back pressure is too large, the motor will be running, the current value of the current is locked rotor current.

- Q: Friends sent the old air conditioning, when the demolition did not receive snow species, snow leakage. We ask people to install air conditioners, and when they find the outdoor air conditioner, the compressor stops for a while, but the fan is turned. The master said to have air conditioning and snow, with a little increase in what is said, 120, the compressor stops, natural snow cannot be added, read and then open the outdoor machine lid said capacitor is good, the conclusion is a bad compressor, and then suggest we change a second-hand room outside the machine.My question is..,When the compressor is out of order, why does it stop? Will there be a possibility, where not installed, the line did not take good and so on?Is there anything else that might have gone wrong?If you change a second-hand outdoor machine, is it also to 1.5P, GREE brand or what? Are there any other requirements?

- The compressor is protected by high voltage, high temperature and overload. After the temperature drops, the compressor is automatically turned back to start operation. After the operation, the temperature rises again, and the overload protection is carried out again.The possible cause of excessive high pressure and its elimination:1, poor heat sink condenser. Check the cooling fan is rotated, the condensing tube if there is dirt, clean the condenser.2, too much refrigerant. Increase the compressor load, resulting in excessive pressure, appropriate to reduce the cooling dose.3, the pipe system is blocked. Refer to the pressure gauge to determine, eliminate, and re process the system.4, fouling or fouling of evaporator or filter screen. The air flow becomes smaller, the system pressure and temperature are not constant, and the evaporator or filter screen is cleaned.5, compressor start capacitor burnout. Capacitors need to be replaced.6, the compressor starting coil burned, unable to start operation, resulting in excessive starting current, protection device jump off. Only replace the compressor one way.

- Q: The refrigerator doesn't refrigerate, but the compressor has a sound. What's the matter?

- No refrigeration, but the compressor has a sound, there may be refrigerant leak, you can check, can not call the customer service to see ~!

- Q: Do you have a compressor for both internal and external machines?

- Only the outdoor air conditioner has a compressor, unless some of the air conditioning has two compressors, the compressor is not indoor.

- Q: My BYD F0, there is an air conditioner switch, but I put the wind speed is 0, that is, the fan does not work, need to switch the A/C air conditioner also press back?I think some of the design of the car is not reasonable, spin to the blue area, but also press the A/C air conditioning switch to refrigeration.When I test the horsepower of the engine, press the A/C air conditioner switch and spin it to the fan 0. It doesn't seem to have any effect on the horsepower. But if you drive to the 1 gear and the 2 gear, you obviously feel the horsepower is scattered.Then, can the A/C air conditioner switch be pressed often, if it doesn't consume energy?

- No, the design is not reasonable. Listen to me and you'll see:Automotive air conditioning design for three commonly used circumstances: 1. winter hot air. Natural fan of spring and autumn 2. 3. summer air conditioning.Natural wind and hot air are controlled directly by hot and cold switch gear.If there is no A/C switch, one opens to the blue area to cool, then a natural wind can not be achieved. And a lot of time is a natural wind to meet the demand.

- Q: The air conditioning compressor works more often than it stops, such as 5 minutes of work and 15 minute stops. Is this normal? Does the country have some standards? If so, please tell me which standard it is.If not normal, how long should the compressor work and how long will it stop?

- With the temperature set on your remote control, the higher the temperature, the shorter the running time of the compressor.

- Q: Refrigerator compressor not stop, okay? What caused it?

- First of all, your refrigerator can not reach normal temperature. The ice thickness is a little different from what it was before. If both doors are fresh and frozen are normal. Or three doors, fresh and chilled, chilled are normal. And freezing is very thick. That's the thermostat is out of order. If it's a computer board, then maybe the temperature sensor is out of order. If it doesn't stop. Freezing and freezing are thinner, that is, lack of snow or leakage.

- Q: The first is the compressor, 2 minutes to start once, start a few seconds after the shutdown, the compressor made a big noise, there is vibration, and then refrigeration, and then not refrigeration. I thought the starter was out of order. Remove the starter and load it. Then I can't start, just hear the click and click. Later, I reloaded the starter for 2 times and then started again, but in the processLong time after power failure in power, compressor stopped after 3 minutes of work has won't start, only to hear the starter Kaka twice, the compressor does not work, but fever. But after an hour of power failure, the compressor starts for the first time and works again, but does not refrigerate, and the fan below is not blowing hot air. (normally hot air) hope to answer the question is personal opinion. Copy paste will not be adopted.

- A way to judge whether the refrigerator is working or not:1. (work 10 minutes) touch the refrigerator on the back, if the fever, that is normal, if not hot, or small heat, refrigerator leakage of fluoride or fluoride. The temperature should be above 35 degrees.2. the normal operation of the compressor means normal breathing and pumping. Not necessarily jitter, it's work. This can only be checked by professional maintenance.

- Q: What's wrong with the air-conditioning compressor not working?

- 1 is the capacitor bad replacement, 2 voltage is not enough, 3 compressor card cylinder or bad card cylinder, you can connect 220V voltage through4 thermal protection

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | 3,000-5,000 square meters |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Vertical Tank Air Compressor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- N/A unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords