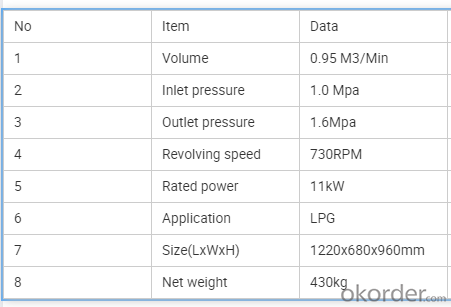

Compressor for LPG with Capacity 0.95m3/min

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product characteristic: ZW series oil-free lubrication liquefied petroleum gas compressor is adopting advanced technology of domestic compressor industry. It is a integrated unit combined with compressor, filter, gas-liquid separator, safety valve, two four-way valve , explosion-proof motor, etc. It has the characteristics of multiple functions, small size, light weight, low power, stable and reliable operation, etc. And it has good safety performance. It can be used to transport liquefied petroleum gas and other liquid with strong volatility and retrieve the gas in the storage tank. Due to the use of a unique oil-free lubrication design, oil lubrication is not needed in the cylinder, thus media will not be polluted, so that the transported material is kept pure.

2. Main usage and application scope

This series of compressors are mainly used for the loading, unloading, transferring, gas recovery and other operations of liquefied petroleum gas. It is an ideal equipment for fluid delivery and gas recovery. Therefore, it is widely used in liquefied petroleum gas storage and distribution station, gas mixing station, gasification station, canning factory, automobile gas station, etc.. It is especially suitable for large, medium and small-sized liquefied petroleum gas stations.

In addition, it is suitable for the liquid delivery and residual gas recovery of the volatile substances with low boiling point, , such as propane, butane and butene. The modified product can be used for liquid delivery and gas recovery of propylene, liquid ammonia, etc..

- Q: Why does the compressor produce liquid shock?

- The cause of a liquid shock in the compressor is:1, excessive refrigerant filling, or throttle valve is too large, or throttle valve failure.2, the unit evaporation area is too small, and the refrigeration capacity of the compressor does not match.3, the cooling area of the evaporator is reduced and the heat transfer is reduced when the evaporator surface is seriously wrapped with frost.4, the compressor has just started operation, because the evaporation temperature is higher at the beginning, and the compressor suction valve is too fast, causing sudden inhalation.5, freon compressor lubricating oil temperature is too low, will work medium in lubricating oil dissolved too much, when the compressor suction, suction pressure drop suddenly. At this point, the oil dissolved in the oil will suddenly evaporate, so that the oil bubble, oil will be inhaled along with the refrigerant in the compressor and cause liquid shock.Liquid hammer occurs mainly in piston compressors. As refrigerant liquid (or lubricating oil) is sucked in by compressor, the liquid is incompressible, which results in abnormal shock of compressor.

- Q: Is 35 on the hook, the indoor machine has been out of the natural wind, outdoor fan whistling, that is, the compressor does not start, there is no response, I would like to ask what is the matter, the air-conditioning is GREE, bought three years ~!!

- Compressor does not start for too many reasons

- Q: Freezer compressor is very hot, it is estimated that 70-80 degrees, inside the copper pipe over a period of time, the above cream on the. What's the problem? What is the normal temperature of the compressor?

- The compressor will be hot after running for a period of time, which is a normal phenomenon

- Q: Why is the design of air-conditioning compressor copper tube bent?

- Reduce the strength of the vibrations produced by the operation of the compressor along the copper tube.The shape and direction of the bends are also exquisite.

- Q: How can I select the air compressor?

- For pressure, displacement, and use

- Q: Is the compressor above the car the same as the air conditioning pump? If so, what's the function of it? Beg for solution?

- Air conditioning pump is the compressor of air conditioning, but do not rule out other compressors on the car

- Q: What are the main differences between the screw air compressor and the piston air compressor?

- From the use of point of view, or screw good, pressure stability, maintenance less, but relatively high maintenance costs

- Q: Why should the piston air compressor have several cylinders, single machine compression and multi-stage compression difference?

- A piston compressor has several cylinders, and usually has several stages of compression. Multistage compression can improve the discharge pressure of the compressed gas not only improves the pressure, and the temperature is very high, up to 200 degrees, so the gas per stage compression after cooling (sub cooled and water cooled), then move on to the next level of compression, improve efficiency.

- Q: What's the three pipe of the refrigerator compressor for? Which one is cooling and which is refrigeration?

- High pressure heat, low pressure cooling, process tube dead head

- Q: Where is the difference between an electronic wine cabinet and a compressor wine cabinet?

- The electronic wine cabinet is an electronic module for refrigerating. When the module is connected with the direct current, the utility model can be cooled. When the module is communicated with the reverse direct current, the utility model can refer to heat!And compressor, wine cabinet is to use compressor to refrigeration!The same is refrigeration! Electronic wine cabinet, small noise, fewer failures, high heat requirements, pay no attention to easy to damage the electronic module, compressor, wine cabinet noise, fault relative to a little more!

Send your message to us

Compressor for LPG with Capacity 0.95m3/min

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords