Laser cladding technology for repair and remanufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 cm²

- Supply Capability:

- 50000 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

In the cement industry, vertical mill, roller press roller and other equipment operating environment are in a very crucial situation with high temperature and serious pollution. Its bearing needs good sealing and protection, in order to ensure the good operation of the equipment.

Our company supplies Smith, Viv, Yubu, Luokuang, China materials, Hefei and other domestic and foreign cement mill, and roller press mill roller seal and hydraulic seal, are the original factory imported products. Brand names are Italian ATS, German DE shi feng, Sweden SKF.

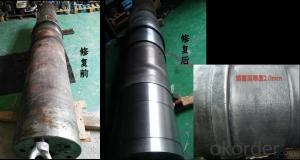

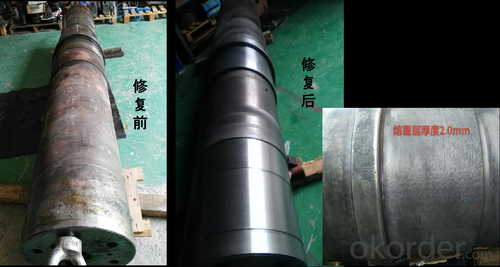

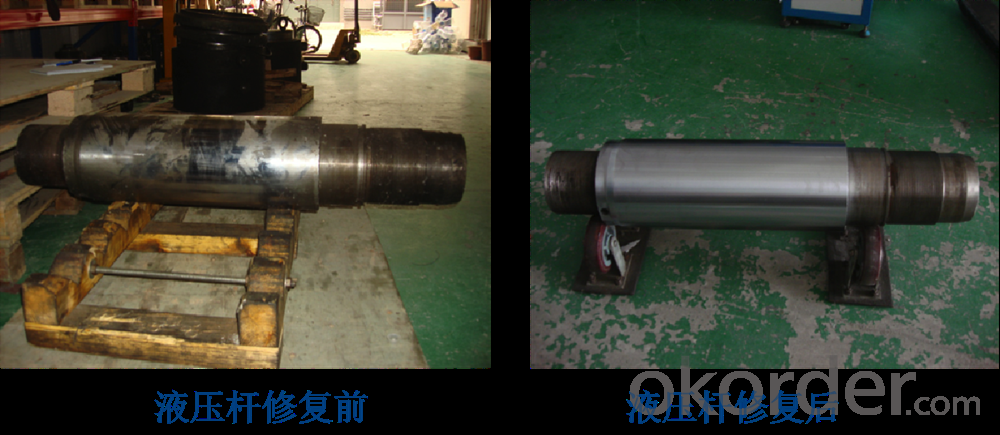

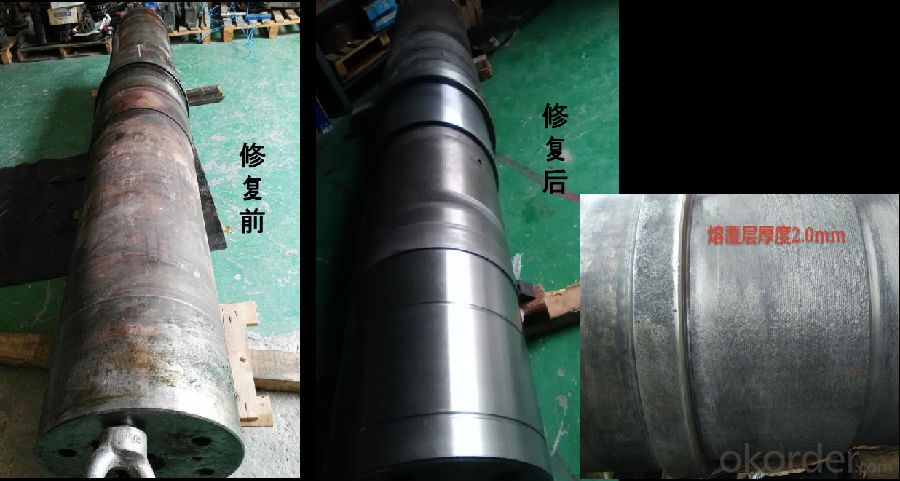

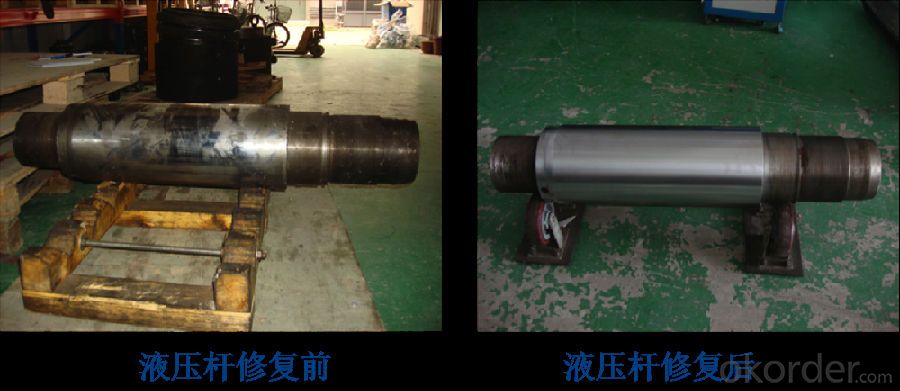

At the same time, Ruipai has been using laser cladding technology to restore and repair the worn parts of equipment in the past ten years, which not only meets the specific requirements of material surface performance, but also saves a lot of maintenance cost and time for the enterprise. Its maintenance feature is to significantly improve the wear resistance, corrosion resistance, heat resistance and oxidation resistance of the matrix surface, so as to achieve the purpose of surface modification or repair.

The goal of Laser cladding technology is to improve the performance of waste equipment, with high quality, high efficiency, energy conservation and environmental protection as the criterion, with advanced technology and industrial production as the means, different from simple "repair", also different from "renovation". Compared with new products, the waste products repaired and transformed can save 50% on cost, 60% on energy and 70% on materials.

Laser cladding Tech

No preheating, local repair, can be restored to the original size after repairing;

Metallurgical bonding, high bonding strength, anti - corrosion and wear - resistant

The repair speed is fast, the follow-up processing is simple, the repair melting pool is even, fine, without cavity, or slag

- Q: Can 1 of the displacement be V6 cylinder or 6 displacement with L4 cylinder?

- In fact, there is no direct relationship between what, 1.0L V6 can be made in theory, but not what is necessary, because the inline engine has its own advantages, and if you do, it is bound to each cylinder can be greatly reduced, so that the engine is of no practical use! And the cost will be high!As a large displacement engine, a straight line if the space occupied by the engine will be large, so large and bulky, the car's head by the pressure is too large, the front must be extended, from a cost perspective, The loss outweighs the gain!

- Q: What's the average number of cylinders in a car? What's the law?

- Inline four cylinder also has more inline three cylinder such as QQ Alto 1 exhaust quantity is 3 cylinder car more than 1.1 more is an inline four cylinder, there are a lot of things such as the 4 cylinder 1.1 exhaust inline four cylinder exhaust should be maximum may the most thing on the market to see the 2.4 peak is over the are also basic V type arrangement of 6 cylinder engines such as Teana. Anyway market mountain car multi part or 4 cylinder 1.6 gold displacement domestic car now for more than 1.5 1.5T but also four cylinder car, row rule is the larger the gas cylinder may response number for small cars. At present, the world cylinder maximum number production model is Bugatti Veyron EB Veyron - 16.4 the car engine is popular R & D 16 cylinder 64 valve engine, with four turbochargers, using W type cylinder layout displacement: 7993 CC in 3 seconds can make the car to reach 100 km/h speed, start to accelerate from standstill to 300 km/h speed the time required for less than 14 seconds

- Q: Like kenisaige CCXR, with only 4.8 V8 engine can output 1032 horsepower, but the output power of ordinary V8 in 300-600 Ma, such as Porsche Panamera turbo with 4.8 V8 output power of the engine, why it is only 500 horsepower, and I see some people on the Internet car, the V6 engine can be changed to 1000 horsepower, and the output power of ordinary V6 engine is only 200-300, this is why?

- The power of the engine mainly depends on engine displacement and displacement speed, when the engine speed is high, the output power of the engine is improved, the speed of the engine to have the corresponding technical guarantee can work reliably in the design and manufacture.In addition, the use of supercharging technology can increase the power of more than 30% of the engine.

- Q: The cylinder in the paper towel. It's not square. One piece of that one

- On the plane where the hard pressed on the other side and then turn 90 degrees again once and then take it out

- Q: A small toy aircraft with an engine model of COX 049 and a piston about 11MM in diameter

- 0. 25-0.8 this is not possible. It should be within 0.01 plus or minus

- Q: Just saw the Audi A8L V12 engine, R8 is V10, the number of cylinders or car always feel good car should be more, so think of? Who can give a detailed account of his views on this subject?What is the purpose of the A8 V12 engine? Is it faster than R8?

- To a certain extent, the heat will be a problemA8 doesn't seem like V12, but W12 doesNo faster than R8, R8 is a sports car after all

- Q: I want to buy a Jetta, it can valve number two, another car is four, really a bit puzzled.

- The valve, as the name suggests, is the inlet and outlet of the valve. When the engine is to work, it has to burn gasoline, and when it is burning, it has air. The valve is the device that controls the intake and discharge of the cylinder. The amount of output and the performance of the engine valve number is a direct influence is undeniable, the design of multi valve intake and exhaust design and the exhaust system, for peak horsepower output absolutely has a critical impact.The valve number of the engine is generally divided into 2 valves per cylinder, or 4 valves per cylinder, and a small number of valves with 5 valves per cylinder. It is worth noting that the car parameters often in two forms of "four cylinder four valve, inline four cylinder 16 valve," said the two represents the engine is four cylinder, 4 valves per cylinder, valve number for 16The number of cylinders used in automobile engines is 3, 4, 5, 6, 8, 10 and 12 cylinders. Displacement of 1 liters below the engine, commonly used 3 cylinder (such as Xiali 7100), 1 - 2.5 liters, usually 4 cylinder engine, 3 liters or so of the engine is generally 6 cylinder, 4 liters or so for the 8 cylinder, more than 5.5 liters with 12 cylinder engine. According to the arrangement of the engine, and can be divided into W type 12 cylinder engine (such as W12, Audi A8W12, Volkswagen Phaeton), V type 12 cylinder engine (such as BMW, Mercedes Benz S600, 760), W type 8 cylinder engine (such as W8, Passat) V 8 cylinder engine (such as Audi A6L4.2), boxer 6 cylinder engine (such as Subaru V, forester) type 6 cylinder engine, inline 5 cylinder engine and inline 4 cylinder engine. Generally speaking, in the same cylinder diameter, cylinder number, larger displacement, higher power; in the same displacement, cylinder number, diameter is smaller, speed can be improved, so as to get bigger promotion power.

- Q: How much is the cylinder pressure of the gasoline engine lower than that of the diesel engine?

- Because diesel is a compression ignition... The gasoline engine ignites the spark through the spark plug to produce an electric spark that ignites the gas mixture!Because the diesel is not easy to ignite, so the compression ignition test! Remember to go to school, teach once, put the cotton into the needle tube, press needle, cotton burning course! This is the principle of diesel fuel... So it's stressful!

- Q: What is the working principle of the cylinder?

- The working mode of the cylinder is divided into the suction stroke, the compression stroke, the work stroke and the exhaust stroke.Two,(1): the intake stroke the intake valve opens, the exhaust valve closes and the downward movement of the piston, a mixture of gasoline and air into the cylinder; (2) the compression stroke, the intake valve and exhaust valve are closed, the piston moves upwards, the fuel mixture is compressed; (3) stroke: at the end of the compression stroke, the spark plug the spark, fuel burning fiercely, gas of high temperature and high pressure. High temperature and high pressure gas pushes the piston downward, which drives the crankshaft to rotate and works externally;(4) exhaust stroke: the intake valve closes, the exhaust valve opens, the piston moves upward, and the exhaust is expelled from the cylinder. (schematic diagram of the following four strokes).?Turn left and turn right |

- Q: What's the difference between a L cylinder and a V cylinder? What's the good news?

- The two different arrangements of the cylinder, the power should be L type to win some (the same displacement), but V type of space saving, technically V type of difficulty

Send your message to us

Laser cladding technology for repair and remanufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 cm²

- Supply Capability:

- 50000 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords