Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

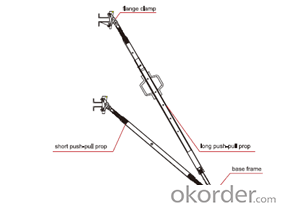

1. Structure of Push Pull Prop

Pull-push prop are used for supporting the wall and column formwork.

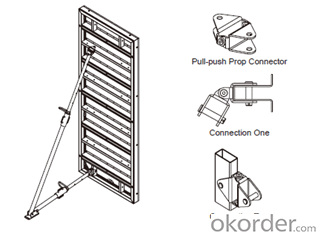

1.) For Timber Beam Formwork

2.) For Steel Frame Formwork

2. Main Features of Push Pull Prop

◆ High degree of standardization

◆ Simple site operations

◆ Quick adjustment

3. Push Pull Prop Images

4. Single Side Bracket Specifications

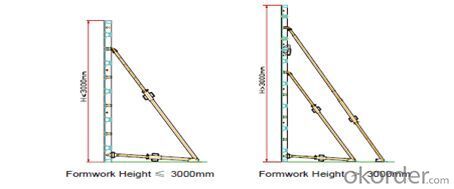

There are three kinds of pull-push props, A,B,C. The A and B is suitable for the formwork not higher than 3000mm; C is suitable for the formwork higher than 3000mm as a reinforcer.

5. FAQ of Single Side Bracket

1) What can we do for you?

.We can ensure the quality of the push pull prop and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Subway construction steel support axial force design value of KN/m, the construction to be converted into MPa, how to calculate?

- If:The design of prestress value is 300KNJack cross-sectional area of 0.017671 square metersApply prestress = Design prestress value / Jack cross-sectional area =300/0.017671/1000=1.70MPa

- Q: How do you prevent steel props from slipping on smooth surfaces?

- There are various measures available for preventing steel props from slipping on smooth surfaces. Here are some options to consider: 1. Incorporate anti-slip pads or mats: Enhance friction between the steel props and the surface by placing anti-slip pads or mats underneath them. These pads are typically made of materials like rubber that offer strong grip properties, effectively preventing slipping. 2. Apply adhesive tapes: Utilize adhesive tapes, such as grip tapes or non-skid tapes, on the base of the steel props. These tapes have a rough surface that boosts friction and stops the props from sliding on smooth surfaces. 3. Ensure weight distribution: Achieve even weight distribution across the surface area of the steel props. This can be accomplished by adding extra weights on top of the props or adjusting the load distribution if feasible. By doing so, the downward pressure increases, resulting in greater friction and reducing the likelihood of slipping. 4. Secure props with clamps or brackets: Use clamps or brackets to firmly fasten the steel props to the surface. This will minimize any movement or shifting that could lead to slipping. 5. Consider implementing floor anchors: In certain cases, it may be necessary to install floor anchors for enhanced stability. These anchors can be drilled into the surface, providing a secure attachment point for the steel props and reducing the risk of slipping. 6. Opt for props with built-in anti-slip features: When selecting steel props, choose models that come with anti-slip features. These props may have specially designed rubber or non-slip coatings on the base, offering better grip on smooth surfaces. It is crucial to evaluate the specific requirements and conditions of the project to determine the most suitable method for preventing steel props from slipping on smooth surfaces.

- Q: What are the common accessories used with steel props?

- Enhancing functionality and ensuring safety on construction sites, steel props are commonly paired with various accessories. These accessories include prop heads, prop plates, prop pins, prop nuts, adjustable prop wrenches, base plates, and scaffolding tubes. Prop heads, typically made from steel or cast iron, provide additional support to the top of the props. They distribute the load evenly, preventing sinking or structural damage. Prop plates, flat steel plates placed beneath the props' base, distribute the load and prevent sinking. They also provide stability and prevent tipping. Long steel pins known as prop pins secure the props at the desired height. Inserted through holes in the props and prop heads, they are locked to prevent loosening during use. Prop nuts are used to secure the prop pins, preventing movement and providing extra stability. An adjustable prop wrench is a specialized tool that easily adjusts the props' height. It grants flexibility and adaptability to varying construction requirements. Base plates, large steel plates, serve as a stable foundation beneath the prop plates. They prevent sinking and tipping by distributing the load. When steel props are used in conjunction with scaffolding systems, scaffolding tubes connect the props horizontally. This creates a sturdy framework for workers to navigate and work on different levels of the construction site. These accessories are crucial for ensuring stability, safety, and adaptability. They not only enhance the functionality of steel props but also contribute to the overall safety of workers and the structural integrity of construction projects.

- Q: What are the safety considerations when using steel props?

- There are several safety considerations to keep in mind when using steel props. Firstly, it is important to ensure that the props are in good condition and free from any defects or damage. Regular inspections should be conducted to identify any signs of wear or structural issues. Secondly, proper installation is crucial to maintain stability and prevent accidents. The props should be securely and correctly positioned, with appropriate bracing and shoring. Additionally, it is essential to adhere to the recommended load capacity and never exceed the maximum weight limit. Lastly, workers should receive adequate training on the safe use and handling of steel props to minimize the risk of injuries.

- Q: Can steel props be used in the construction of railway bridges or tunnels?

- Yes, steel props can be used in the construction of railway bridges or tunnels. Steel props are commonly used as temporary supports during the construction process. They provide stability and structural integrity to the bridge or tunnel until the permanent structures are in place. Steel props are known for their strength and load-bearing capacity, making them suitable for supporting heavy loads and ensuring the safety of the construction site. Additionally, steel props can be easily adjusted and reused for different construction projects, making them a cost-effective choice for railway bridge and tunnel construction.

- Q: Are steel props adjustable in tight spaces?

- Steel props, widely known as adjustable steel props or steel shores, can be conveniently adjusted in compact areas. These props, frequently employed in construction projects, serve as temporary supports for structures like formwork, scaffolding, or beams. Their composition includes a steel tube with an externally threaded section and an inner tube that smoothly slides within the outer tube. This ingenious design enables effortless alteration of height levels while guaranteeing stability and the ability to bear heavy loads. In confined spaces where mobility may be restricted, the adaptability of steel props permits accurate placement and reliable support, rendering them ideal for a multitude of construction situations.

- Q: Are steel props resistant to electromagnetic interference (EMI)?

- Yes, steel props are generally resistant to electromagnetic interference (EMI) due to their high conductivity and shielding properties.

- Q: How do steel props compare to wooden props?

- Steel props are generally considered to be superior to wooden props in terms of strength and durability. Steel props are made from high-quality steel, which provides a higher load-bearing capacity compared to wooden props. This means that steel props can support heavier loads and offer greater stability, making them suitable for a wide range of construction projects. In addition to their strength, steel props are also more resistant to wear and tear compared to wooden props. They are less susceptible to damage from moisture, insects, and warping, which can be common issues with wooden props. This makes steel props a more reliable and long-lasting option, reducing the need for frequent replacements or repairs. Furthermore, steel props offer more flexibility in terms of adjustment. They usually come with adjustable height mechanisms, allowing for precise adjustments to match varying construction requirements. This adjustability feature is not typically available with wooden props, which often have fixed lengths. While wooden props may be a cheaper initial investment, they tend to have a shorter lifespan and may require more frequent maintenance and replacements. Steel props, on the other hand, may have a higher upfront cost but provide a better return on investment due to their durability and longevity. Overall, steel props are a preferred choice for construction projects where strength, stability, and longevity are crucial. They offer superior load-bearing capacity, resistance to wear and tear, and adjustable height mechanisms, making them a reliable and efficient choice for builders and contractors.

- Q: Are steel props suitable for supporting heavy structures?

- Indeed, steel props are well-suited for the support of substantial structures. Renowned for its robustness and resilience, steel emerges as an impeccable substance for bearing weighty loads. Termed as steel shoring or steel shores, steel props frequently find application in construction undertakings by offering temporary support to structures during their erection or refurbishment. These props possess adjustability, facilitating effortless extension or retraction to accommodate diverse heights and weight specifications. Furthermore, the design of steel props guarantees an equitable distribution of the load, thereby ensuring stability and averting any slumping or collapse of the edifice. In essence, steel props represent a dependable and efficacious solution for bolstering heavy structures.

- Q: Can steel props be used for supporting temporary roofing structures?

- Steel props, which are also referred to as adjustable steel props or acrow props, can be utilized to provide support for temporary roofing structures. These props are commonly employed in the construction field to offer assistance for temporary structures including roofs, walls, and formwork. Their adaptability enables easy adjustment to the desired height, making them suitable for a variety of construction applications. Steel props possess robustness and durability, ensuring reliable support for temporary roofing structures. Moreover, they can be effortlessly installed and dismantled, facilitating efficient construction processes. Overall, steel props are widely favored for their strength, adjustability, and user-friendly nature when it comes to supporting temporary roofing structures.

Send your message to us

Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords