Vertical Multistage Stainless Steel Centrifugal Pump Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Vertical Multistage Stainless Steel Centrifugal Pump Price

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.My company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.My company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

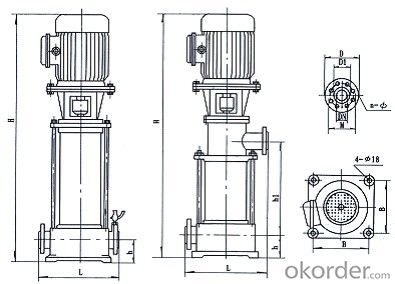

Product parameters of Vertical Multistage Stainless Steel Centrifugal Pump

Capacity | up to 250 m3/h |

Head | up to305m |

Speed | up to 3600rpm |

Power | up to 200kw |

Voltage | 220V to 480V |

Temperature range | Within 120 Deg C |

Working pressure | Within 40bar |

Application of Vertical Multistage Stainless Steel Centrifugal Pump

It can be used to convey various medium from tap water to industrial liquid at different temperature and with different flow rate and pressure.

CDL type is applicable to conveying non-corrosive liquid, While CDLF is suitable for slightly corrosive liquid.

Water supply: Water filter and transport in Waterworks, boosting of main pipeline, boosting in high-rise buildings.

Industrial boosting: Process flow water system, cleaning system, high-pressure washing system, fire fighting system.

Industrial liquid conveying: Cooling and air-conditioning system, boiler water supply and condensing system, machine-associated purpose, acids and alkali .

Water treatment: Ultrafiltration system, reverse osmosis system, distillation system, swimming pool, separator.

Irrigation: Farmland irrigation, spray irrigation, dripping irrigation

Operation Condition of Vertical Multistage Stainless Steel Centrifugal Pump

Thin, clean, non-flammable and non-explosive liquid containing no solid granules and fibers.

Liquid temperature:

Normal temperature type: -15~+70,

Hot water type: +70~+120

Ambient temperature: Up to +40

Altitude: Up to 1000m

Electric Motor of Vertical Multistage Stainless Steel Centrifugal Pump

Full-enclosed air-blast two-pole standed motor

Protection class: IP55

Insulation class: F

Standard voltage

50Hz:

1x220230/240V

3x200220/346380V

3x220240/380415V

3x380415V

60Hz:

3X200230/346400V

3x220255/380440V

3x220227/380480V

Picture Show of Vertical Multistage Stainless Steel Centrifugal Pump Price

Why Choose Us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

Transportation

- Q: What does the temperature range of the pump mean?

- Not be too cold or hot water, will be frozen.

- Q: I'm doing a DCP project which is at its concept design stage.In order to estimate the chilled water pump size and ratings roughly, could anybody give me some tips on the average/normal chilled water pump heads for a typical 10000 TR DCP. The length of the longest loop could be around 600 m single run.

- to boot to the availability and go back line, if there are different factors in the equipment at the same time with administration valves and warmth exchangers, their rigidity drop also desires to be protected.

- Q: 7.63Determine the isentropic efficency of a water pump when water enters as a saturated liquid at 96.5 kPa and exits at 5 MPa and 106 degrees C.Thanks

- Well!!!!!!!! Isentroipc Efficiency of a pump = Isentropic Work / Actual Work At state 1, Enthalpy of Saturated Liquid h1 = 413.357 kJ/kg Entopy s1 = 1.29154 kJ/kg-K At state 2, Enthalpy of Liquid at state 2 = 448.042 kJ/kg Now, to find the ideal Enthaply , Enthalpy at 5 M Pa at entropy of 1.29154 kJ/kg-K h2s = 418.462 kJ/kg Thus, Isentropic Work Done I = h2s - h1 = 418.462 - 413.357 = 5.105 kJ/kg Actual Work Done A = h2- h1 = 448.042 - 413.357 = 34.685 kJ/kg Hence, Isentropic Efficiency = I/A = 5.105/34.685 = 14.72%

- Q: I have built my own spray rig to water some stock and tanks and a garden. It is a 330 gallon tank and has a spout at the bottom that i am going to connect a multi purpose pump to. My question is what size pump would i need? I have been looking at Atwoods and Tractor Supply and have seen some 2.1 GPM and a 5 GPM pumps i just don't know which would best suit me. i am planning on having the tank on the trailor and running water hose to a sprinkler or two. I would like to know how man sprinklers are possible on this type of system and still keep good pressure. Thanks for any answers.

- Like the last person, what you've looked at won't do much. Just think of a 5 gal bucket and how fast do you want to fill it up. Also you want pressure behind this water if you want to water with it, so look at the psi on a pump as well as the GMP to determine what will work best for you. I'd say 40psi should be enough pressure to run hoses and sprinklers and remember that the smaller the hose at the end gives the highest pressures. Hope this helps you out some. I'll admit, I'm thinking of this as knowledge of water pressures more than GMP, but I think I've explained something good about your question. Good LUCK

- Q: I am looking for a small water pump that I can turn on and off using a computer, preferably via USB. If someone could please post a link or a method of me doing this myself, I will be very appreciative.

- I'd look for a USB IO module, add a relay, and switch a standard pump.

- Q: the outboard runs fine and pumps water out with muffs on but when i put it in the water it doesn't pump any water at all. could it be that the impeller needs replacing? what do you think?thanks

- No question about it. Replace the impeller. It's easy - the hard part is getting the fasteners off without breaking a stud. Be patient and use liquid wrench and give it an hour or more to work. Tap the nuts and then try them. A final resort would be careful (very careful) use of a propane torch to free the nuts. If not replaced, eventually blades will break off the impeller and foul the cooling system.... which can be a very expensive and difficult repair.....overheating is also very bad for the engine.... so fix the water pump.

- Q: My water pump is starting to leak. The shops are quoting $250- $300 to replace but I can buy a water pump at the auto parts store and install myself for less than $100 but I don't know what all is involved with this repair or if I should try (my only experience with car repair up to now is recently replacing the alternator). If anyone has done this please let me know what you think. thanks

- 1. okorder /

- Q: im buying a mazda 626 for 800 abd the owner selling just let me know that the water pump is going out. is it a fairly easy fix or should i keep shopping for a vehicle?

- do it yourself or pay someone else? call different shops in your area for a estimate before buying it call more than one on the sly from my experience, on the low side, about $300 up to about $500 but $800 is a good cheap deal for a 95 model and Mazda is a good car that lasts forever and is good on gas but he may be lying to you, it may very well be the headgaskets actually leaking........$1200

- Q: we changed the water pump it went bad and there is still a knock in it please help it is running really sluggish

- I'm assuming you replaced the water pump due to an overheating problem (most water pumps fail due to leakage, so I'm assuming you drove the car with low coolant). If this is the case and you have an engine knock, you're in trouble. A knock signifies damage to the crankshaft/piston/connecting rod and the associated bearings. If it sounds like someone is hitting the engine with a hammer, you'll need to bring it in right away, before you do more damage. It's not going to be cheap (when is it with a BMW) and you may be better off selling the car and starting with a new car. Good luck. Greg

- Q: Sewage treatment plant design how many pumps should be selected, head how to calculate the maximum design flow is 833M3/h

- Is the sewage treatment bar, you have to choose corrosion-resistant pump, sewage treatment lift is generally not high, and then you flow so much, the choice of axial flow pump is the best choice, specific models only you go online to check. The information I provide is the choice of corrosion resistant axial pumps. Then, if there is impurities, it is best to use the axial flow pump with mixing function.

Send your message to us

Vertical Multistage Stainless Steel Centrifugal Pump Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords