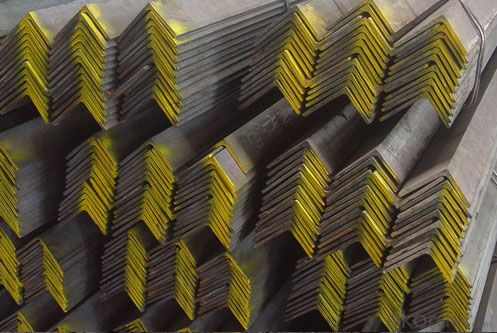

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

OKorder is offering Unequal Angle Steel Famous Style Low Alloy For Profile Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

Unequal Angle Steel Famous Style Low Alloy For Profile Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

OKorder'sUnequal Angle Steel Famous Style Low Alloy For Profile Steel are durable, strong, and resist corrosion.

Main Product Features of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

1.Standard: GB,ASTM,JIS

2.Steel Grade:Q195-Q420

3.Length: 5.8-12mm

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

| ||

Thickness | 12mm | |

3mm-25mm | 20mm-200mm | |

Length

| 5.8-12M , according to customers' requirements | |

Standard

| GB,JIS,ASTM,EN,DIN | |

Material

| 304 304L 316 321 | |

Type | Equal and unequal | |

Usage

| constructions,communication towers and so on. | |

Certification

| ISO9001,ISO9002,API | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays

Advantages of Unequal Angle Steel Famous Style Low Alloy For Profile Steel

1. Convenient in construction and save much time and labor.

2. Light, good quality and reasonable price.

3. The shape and specification can be made by customer's requirement.

4. High mechanical strength.

5. Attractive in appearance and reasonable designs.

- Q: How do steel angles perform under seismic loads?

- Steel angles perform well under seismic loads due to their inherent structural properties. The L-shape of steel angles provides excellent resistance to bending and torsion forces, making them ideal for withstanding the lateral forces generated during earthquakes. Additionally, their high strength-to-weight ratio and ductility allow them to absorb and dissipate seismic energy effectively, minimizing the potential for structural failure and ensuring the safety of the building.

- Q: What is the standard tolerance for steel angles?

- The standard tolerance for steel angles typically ranges from +/- 1/8 inch to +/- 1/4 inch, depending on the specific dimensions and requirements of the angle.

- Q: What are the different methods of fire protection for steel angles?

- There are several different methods of fire protection for steel angles, depending on the specific requirements and regulations. Some common methods include: 1. Passive Fire Protection: This involves applying fire-resistant materials directly to the steel angles. These materials can include fire-resistant coatings, fireproofing sprays, or intumescent paints. These coatings can help delay the spread of fire and provide insulation, protecting the steel angles from the high temperatures produced during a fire. 2. Encasement: Another method is to encase the steel angles in fire-resistant materials such as concrete or gypsum board. This creates a barrier between the steel and the fire, preventing it from reaching critical temperatures that could cause structural failure. 3. Fireproofing Systems: Fireproofing systems involve the use of fire-resistant boards or panels that are attached to the steel angles. These systems provide a layer of insulation and protection against fire, preventing the steel from heating up quickly and maintaining its structural integrity for a longer period. 4. Sprinkler Systems: Installing sprinkler systems can also help protect steel angles from fire. These systems are designed to detect and suppress fires by releasing water or fire-suppressing agents when triggered. By quickly extinguishing the fire, the sprinklers can prevent the steel angles from reaching critical temperatures. 5. Fire-resistant barriers: Fire-resistant barriers, such as fire-resistant walls or curtains, can be utilized to separate steel angles from potential fire sources. These barriers can help contain the fire and prevent it from spreading to the steel angles, providing an additional layer of protection. It is important to consult with fire protection experts, engineers, and local building codes to determine the most suitable method of fire protection for steel angles in a specific setting. The choice of method may depend on factors such as the type of building, fire safety requirements, and the level of fire risk involved.

- Q: Are steel angles available in different alloys?

- Different alloys are available for steel angles, providing a wide range of options. Typically, steel angles are made from carbon steel, which is a versatile and common type of steel. However, specific applications may call for other alloys. For instance, stainless steel angles are made from an alloy containing chromium, offering increased resistance to corrosion. In addition, high-strength low-alloy (HSLA) steel angles combine carbon steel with small amounts of elements like manganese, phosphorus, or sulfur to enhance strength and durability. This variety of alloys allows for a diverse range of applications and properties to meet specific needs across various industries.

- Q: What is the typical corrosion rate of steel angles?

- The typical corrosion rate of steel angles can be influenced by various factors, such as environmental conditions, the type of steel utilized, and the presence of protective coatings. In general, steel angles are prone to corrosion due to their iron content. However, by properly maintaining them and applying protective measures, the corrosion rate can be significantly reduced. In mild atmospheres or indoor settings with low humidity and minimal exposure to corrosive substances, the corrosion rate of steel angles tends to be relatively low, typically ranging from 0.1 to 0.5 mils per year (1 mil equals 0.001 inches). This slow corrosion rate enables steel angles to maintain their structural integrity for a long time. On the other hand, in more aggressive environments like coastal areas with high salt levels in the air or industrial settings with chemical exposure, the corrosion rate can be considerably higher. In these scenarios, the corrosion rate of steel angles can range from 0.5 to 2 mils per year, or even higher. It is crucial in such environments to implement measures such as regular inspection, cleaning, and the application of protective coatings to mitigate the corrosion rate and extend the lifespan of the steel angles. It is important to note that these corrosion rates are estimated averages, and actual rates may vary depending on the specific conditions and factors mentioned earlier. Seeking advice from a corrosion engineer or utilizing corrosion rate data specific to the environment and steel type can provide a more accurate estimation of the typical corrosion rate for steel angles in a particular situation.

- Q: What are the different types of steel angle connections?

- There are several different types of steel angle connections commonly used in construction and engineering projects. Some of the main types include: 1. Welded connections: This is one of the most common and traditional methods of connecting steel angles. In this type of connection, the two angles are joined together by welding them at the point of contact. Welded connections provide excellent strength and rigidity, making them suitable for heavy-duty applications. 2. Bolted connections: Bolted connections involve using bolts and nuts to fasten the steel angles together. This method allows for easy disassembly and reassembly of the structure if needed. Bolted connections are often used in situations where frequent adjustments or modifications are required. 3. Riveted connections: Riveted connections involve using rivets to join the steel angles together. Rivets are metal fasteners that are inserted through pre-drilled holes in the angles and then hammered or pressed to secure them. Riveted connections were widely used in older structures and are still occasionally used in certain applications today. 4. Clipped connections: Clipped connections are a type of bolted connection where the angles are connected using special clip angles. These clip angles are bolted to the main angles, providing a secure and rigid connection. Clipped connections are commonly used in steel trusses and frameworks. 5. Gusset plate connections: Gusset plate connections involve using a steel plate, known as a gusset plate, to connect two or more steel angles. The gusset plate is usually bolted or welded to the angles, providing additional strength and stability. This type of connection is often used in structures subjected to heavy loads or dynamic forces. Each type of steel angle connection has its own advantages and disadvantages, and the choice of connection method depends on various factors such as the load requirements, structural design, and project specifications.

- Q: What is the typical thickness of the flanges of a steel angle?

- The thickness of the flanges of a steel angle can differ depending on the particular application and industry norms. Typically, flanges of a steel angle are often available in thicknesses ranging from 1/8 inch to 3/4 inch. It is significant to consider that thicker flanges offer greater strength and stability, but also contribute to the weight and cost of the steel angle. To determine the suitable flange thickness, one should consider the specific project requirements and any relevant engineering or design standards.

- Q: What is the cost of steel angles compared to other structural materials?

- The cost of steel angles compared to other structural materials can vary depending on various factors such as market conditions, availability, and specific requirements. However, in general, steel angles tend to be a cost-effective option for structural applications. Compared to materials like concrete or timber, steel angles are often considered more affordable due to their relatively low production costs. Steel is a widely available material, and its production processes have been optimized over the years, resulting in competitive pricing. Additionally, steel angles offer excellent strength-to-weight ratio, allowing for lighter and more cost-efficient structural designs. When compared to other metals like aluminum or stainless steel, steel angles are typically more cost-effective. While aluminum and stainless steel offer certain advantages in terms of corrosion resistance or aesthetic appeal, they tend to be more expensive due to their production processes and material properties. It is important to note that the exact cost of steel angles can vary depending on the specific dimensions, quality, and quantity required. Prices may also fluctuate based on market conditions, such as changes in raw material costs or global supply and demand dynamics. Therefore, it is recommended to consult with suppliers or industry professionals to get accurate and up-to-date pricing information for steel angles.

- Q: How do steel angles contribute to the stability of a structure?

- Steel angles contribute to the stability of a structure in several ways. First and foremost, steel angles are commonly used as structural members in various applications such as buildings, bridges, and towers. They provide strength and stability to the overall structure. The unique shape of steel angles, with one side longer than the other, allows them to resist both compression and tension forces, making them perfect for carrying heavy loads. Furthermore, steel angles are often used to create rigid connections between different structural components. By welding or bolting steel angles at critical joints, they help distribute the load evenly and prevent excessive movement or deformation. This enhances the overall stability and integrity of the structure, especially during dynamic loads such as wind or seismic forces. In addition, steel angles can also be utilized as bracing elements. Bracing is crucial for resisting lateral forces like wind or earthquake loads. By strategically placing steel angles diagonally between structural members, they create a triangulated system that improves the overall stability of the structure. This bracing helps prevent excessive sway or deflection, ensuring the structure remains rigid and secure. Moreover, steel angles are highly durable and resistant to corrosion, which is essential for the long-term stability of a structure. They can withstand harsh environmental conditions, including exposure to moisture, UV radiation, and temperature fluctuations. This durability ensures that steel angles maintain their structural integrity over time, providing ongoing stability and safety. Overall, steel angles play a vital role in ensuring the stability of a structure. Their ability to resist both compression and tension forces, create rigid connections, act as bracing elements, and their durability make them indispensable in various construction projects. By incorporating steel angles in the design and construction process, engineers can enhance the stability, strength, and safety of the structure, ultimately providing a reliable and long-lasting solution.

- Q: Can steel angles be used in railway infrastructure?

- Yes, steel angles can be used in railway infrastructure. They are commonly used in the construction of railway tracks, bridges, and other structures due to their high strength, durability, and ability to withstand heavy loads. Steel angles provide structural support and stability, making them an essential component in railway infrastructure projects.

Send your message to us

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords