Unequal Angle Steel Carbon steel L profile ASTM Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Steel Carbon steel L profile ASTM Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Carbon steel L profile ASTM Standard are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Carbon steel L profile ASTM Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Packaging & Delivery of Hot Rolled Unequal Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

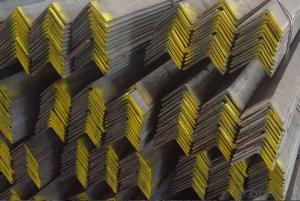

Images:

- Q: What is the typical shear strength of steel angles?

- The shear strength of steel angles can vary depending on several factors such as the grade of steel, the size and shape of the angle, and adherence to industry standards or specific applications. However, steel angles generally possess high shear strength. For standard structural steel angles, the shear strength typically ranges from around 50,000 to 75,000 pounds per square inch (psi). This range is applicable to common steel grades including A36, A572, and A588. These angles find frequent use in construction, infrastructure, and engineering projects where shear forces are of concern. It is important to acknowledge that the shear strength of steel angles can be influenced by additional factors such as the presence of holes or notches, welding or fabrication processes, and the overall design and load distribution. Hence, it is crucial to consult relevant design codes or engineering specifications to ascertain the specific shear strength requirements for a given application. To ensure the accurate determination of shear strength for steel angles in a particular project, it is recommended to consult with a structural engineer or an experienced professional.

- Q: What are the standard dimensions for equal leg steel angles?

- The dimensions of equal leg steel angles differ based on the industry and country. Generally, these dimensions are determined by the length of each leg and the thickness of the angle. Leg lengths commonly range from 20mm to 200mm, while thicknesses range from 3mm to 20mm. These measurements are typically expressed in millimeters and can be further adjusted to suit specific project needs. To ascertain the precise dimensions for equal leg steel angles in a given situation, it is crucial to refer to industry standards and specifications.

- Q: What are the different types of steel angles used in bridge construction?

- Some common types of steel angles used in bridge construction include equal leg angles, unequal leg angles, and L-shaped angles. These angles are often used to provide structural support and reinforcement in various bridge components, such as beams, columns, and bracings.

- Q: Can steel angles be used for overhead cranes?

- Yes, steel angles can be used for overhead cranes. Steel angles provide structural support and stability to the crane, making them a suitable choice for constructing the framework of overhead cranes. They are strong, durable, and capable of withstanding heavy loads, making them an ideal material for such applications.

- Q: What are the different methods of surface preparation for steel angles?

- Some of the different methods of surface preparation for steel angles include abrasive blasting, chemical cleaning, and mechanical cleaning. Abrasive blasting involves using a high-pressure stream of abrasive material to remove rust, scale, and other contaminants from the surface of the steel. Chemical cleaning involves using chemicals to dissolve and remove rust and other contaminants. Mechanical cleaning involves using tools such as wire brushes or sandpaper to physically scrape or scrub the surface of the steel to remove rust and other contaminants. These methods are important in preparing the steel surface for painting, coating, or other forms of protection against corrosion.

- Q: Can steel angles be used for framing partitions and walls?

- Yes, steel angles can be used for framing partitions and walls. Steel angles are commonly used in construction for their strength and durability. They can be used to create a framework for partitions and walls by providing structural support and stability. Steel angles are versatile and can be easily cut and welded to fit the desired dimensions and angles. They are also resistant to fire, pests, and moisture, making them a suitable choice for framing interior walls and partitions in both commercial and residential buildings.

- Q: How do you protect steel angles from abrasive wear?

- There are multiple techniques available for safeguarding steel angles against abrasive wear. An effective approach involves the application of a protective coating or paint onto the steel surface. This coating acts as a barrier, preventing direct contact between the steel and abrasive substances, thereby reducing wear. It is crucial to select a coating specifically designed to resist abrasion, such as epoxy or polyurethane coatings. Another method entails utilizing rubber or polyurethane liners. These liners can be affixed to the steel angles, offering a cushioning effect and safeguarding against direct contact with abrasive materials. They find widespread usage in applications where steel angles are subjected to high levels of abrasion, such as mining or bulk material handling. In certain instances, it might be necessary to reinforce the steel angles with additional materials. This can be achieved by welding or bolting on wear plates or inserts composed of hardened substances like chromium carbide overlay or ceramic. These materials possess exceptional resistance to abrasion and can significantly prolong the lifespan of steel angles in abrasive environments. Regular maintenance and inspection also play a pivotal role in protecting steel angles from abrasive wear. By frequently examining the angles for indications of wear or damage, any issues can be promptly addressed, thereby preventing further deterioration. Additionally, implementing appropriate lubrication and cleaning practices can help minimize the adverse effects of abrasion on the steel angles. In conclusion, safeguarding steel angles from abrasive wear necessitates a combination of preventive measures, including coatings, liners, reinforcements, and regular maintenance. By implementing these strategies, the durability and performance of steel angles can be substantially enhanced in abrasive environments.

- Q: What are the maximum allowable lengths for steel angles?

- The maximum allowable lengths for steel angles can vary depending on the specific application and industry standards. However, in general, steel angles can be manufactured and supplied in standard lengths ranging from 20 feet to 40 feet. These lengths are commonly used in construction, engineering, and fabrication projects.

- Q: How do steel angles resist bending or deflection?

- Steel angles are able to resist bending or deflection because of their shape and material properties. The L-shaped cross-section of steel angles contributes to their structural stability and strength, resulting in a high resistance to bending or deflection under load. The L-shape of steel angles creates two legs that are perpendicular to each other. This design allows for a more efficient distribution of the applied load compared to other shapes. As a result, the angles are able to resist bending forces, preventing significant deformation or deflection. The longer leg of the angle provides greater leverage and stiffness, further enhancing its resistance to bending. In addition to the shape, steel itself is a strong and rigid material known for its high tensile and compressive strength. Steel angles are typically made from hot-rolled steel, which undergoes a process that improves its structural properties. The combination of the L-shape design and the inherent strength of steel enables steel angles to withstand bending forces without significant deflection. Furthermore, steel angles can be reinforced through methods such as welding or bolting to increase their resistance to bending or deflection. These reinforcements add extra strength and stiffness to the angles, making them even more robust and capable of handling higher loads. To summarize, steel angles resist bending or deflection due to their L-shape design, the inherent strength of steel, and possible reinforcements. These factors work together to provide structural stability and prevent excessive deformation, making steel angles a reliable choice for various construction and engineering applications.

- Q: Can steel angles be used in bridges?

- Indeed, bridges can utilize steel angles. Due to their versatility and structural strength, steel angles are frequently employed in bridge construction. They can serve as the primary framework, offer support and reinforcement, as well as connect various structural elements. The ease with which steel angles can be welded or bolted to other steel components makes them particularly advantageous for bridge construction, facilitating efficient and long-lasting construction. Moreover, steel angles exhibit exceptional resistance to corrosion, rendering them suitable for bridges exposed to severe environmental conditions. All in all, incorporating steel angles into bridge designs proves to be a dependable and cost-effective decision.

Send your message to us

Unequal Angle Steel Carbon steel L profile ASTM Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords