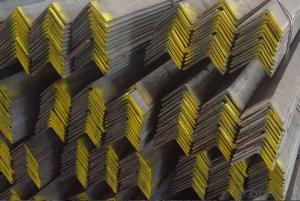

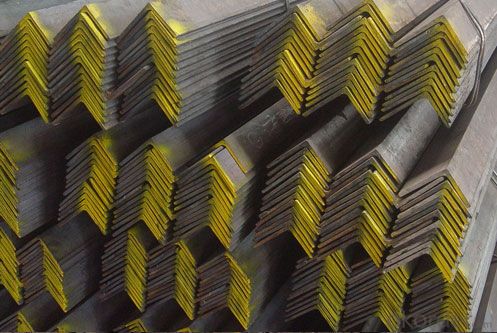

Unequal Angle Steel Factory Price Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Steel Factory Price Carbon Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Factory Price Carbon Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Factory Price Carbon Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

HOT SALE CARBON STEEL ANGLES MOQ:1 TON

1. Competitive price

2. Good quality

3. Fast delivery

4. Best service

Standard Sectional Dimension mm mm | Weight kg/m | Standard Sectional Dimension mm mm | Weight kg/m |

25*25*3 | 1.12 | 90*90*6 | 8.28 |

30*30*3 | 1.36 | 90*90*7 | 9.59 |

40*40*3 | 1.83 | 90*90*10 | 13.3 |

40*40*5 | 2.95 | 100*100*7 | 10.7 |

45*45*4 | 2.74 | 100*100*10 | 14.9 |

45*45*5 | 3.38 | 100*100*13 | 19.1 |

50*50*4 | 3.06 | 120*120*8 | 14.7 |

50*50*6 | 4.43 | 130*130*9 | 17.9 |

60*60*4 | 3.68 | 130*130*12 | 23.4 |

60*60*5 | 4.55 | 130*130*15 | 28.8 |

60*60*6 | 5.37 | 150*150*12 | 27.3 |

65*65*6 | 5.91 | 150*150*15 | 33.6 |

65*65*8 | 7.66 | 150*150*19 | 41.9 |

70*70*6 | 6.38 | 175*175*12 | 31.8 |

75*75*6 | 6.85 | 175*175*15 | 39.4 |

75*75*9 | 9.96 | 200*200*15 | 45.3 |

80*80*6 | 7.32 | 200*200*20 | 59.7 |

80*80*7 | 8.48 | 200*200*25 | 73.6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel angles perform in corrosive environments?

- Steel angles typically have good performance in corrosive environments, but their resistance to corrosion depends on the type and grade of steel used. In general, steel angles made from stainless steel or galvanized steel are more resistant to corrosion compared to carbon steel angles. Stainless steel angles contain chromium, which forms a passive layer on the surface that helps protect against corrosion. This makes them highly resistant to rust and other forms of corrosion, even in highly corrosive environments such as saltwater or chemical plants. Galvanized steel angles are steel angles that have been coated with a layer of zinc. This zinc coating acts as a sacrificial barrier, protecting the underlying steel from corrosion. Galvanized steel angles are particularly effective in environments with high humidity or exposure to moisture, as the zinc coating provides excellent corrosion resistance. On the other hand, carbon steel angles are more susceptible to corrosion. Without any protective coating, carbon steel angles can rust and corrode when exposed to moisture or corrosive substances. However, there are various methods to enhance the corrosion resistance of carbon steel angles, such as applying protective coatings or using corrosion inhibitors. In summary, steel angles can perform well in corrosive environments, but the choice of steel grade and protective measures is crucial for their long-term corrosion resistance. Stainless steel angles and galvanized steel angles are generally preferred for their superior corrosion resistance, while carbon steel angles require additional protection to ensure their durability in corrosive environments.

- Q: How do steel angles behave under seismic forces?

- The behavior of steel angles under seismic forces varies depending on their design, size, and connection details. Generally, steel angles are commonly utilized in seismic-resistant structures because they can dissipate energy and withstand lateral forces. Here are several important characteristics regarding the behavior of steel angles under seismic forces: 1. Ductility: Steel angles possess a high level of ductility, allowing them to undergo significant deformations without failure. This characteristic is crucial in seismic design as it enables the structure to absorb and dissipate energy during an earthquake, thereby preventing sudden collapse. 2. Flexibility: Steel angles have the ability to flex and bend when subjected to seismic forces, which enables them to absorb energy and minimize the impact on the overall structure. This flexibility aids in distributing the seismic forces evenly throughout the structure, reducing localized damage. 3. Connection behavior: Proper connection design is vital to ensure the performance of steel angles under seismic forces. The connections must be designed to allow for rotation and accommodate the anticipated displacements during an earthquake. Adequate connections prevent the angles from becoming brittle or failing prematurely. 4. Buckling resistance: Steel angles are prone to buckling under compression forces. To enhance their resistance to buckling, lateral bracing or stiffeners are often utilized. These components offer additional support to the angles and help prevent buckling during seismic events. 5. Strength and stiffness: Steel angles possess high strength and stiffness, enabling them to withstand the lateral forces induced by an earthquake. The strength of steel angles can be enhanced by selecting appropriate materials, such as using higher-grade steel with greater yield strength. In conclusion, steel angles are well-suited for seismic-resistant structures due to their ductility, flexibility, and strength. However, their behavior under seismic forces is heavily dependent on proper design, connection details, and adherence to seismic codes and standards. It is crucial to consult with structural engineers and follow best practices to ensure the optimal performance of steel angles in seismic design.

- Q: Are there any environmental concerns associated with steel angles?

- Yes, there are several environmental concerns associated with steel angles. One of the main concerns is the production process of steel angles, which involves the extraction of iron ore, coal mining for coke production, and the emission of greenhouse gases during the steelmaking process. These activities contribute to deforestation, air pollution, and climate change. Additionally, the disposal of steel angles at the end of their life cycle can be problematic. Steel is not biodegradable and can take hundreds of years to decompose in landfills. Improper disposal of steel angles can lead to soil and water contamination, posing a risk to ecosystems and human health. Furthermore, the transportation of steel angles from production facilities to construction sites can contribute to carbon emissions and air pollution. The energy required for transportation increases the overall environmental impact of steel angles. To mitigate these environmental concerns, there are several strategies that can be adopted. Firstly, using recycled steel instead of virgin steel can significantly reduce the environmental footprint of steel angles. Additionally, implementing energy-efficient technologies in the steel production process can help minimize greenhouse gas emissions. Finally, responsible disposal and recycling of steel angles at the end of their life cycle can help reduce the environmental impact.

- Q: What are the different testing methods for steel angles?

- There are several testing methods for steel angles, including visual inspection, dimensional measurement, hardness testing, chemical analysis, and mechanical testing. Visual inspection involves examining the angles for any visual defects or irregularities. Dimensional measurement ensures that the angles meet the specified size and shape requirements. Hardness testing determines the hardness of the steel, which is an important factor in its strength and durability. Chemical analysis is performed to check the composition and purity of the steel, ensuring that it meets the required standards. Mechanical testing involves subjecting the steel angles to various loads and stresses to evaluate their mechanical properties such as strength and ductility.

- Q: How do you calculate the bending stress in a steel angle?

- To calculate the bending stress in a steel angle, you need to understand the basics of bending moment and the moment of inertia of the angle. First, you will need to determine the bending moment acting on the steel angle. This can be done by considering the applied load or force and its distance from the point of rotation. The bending moment is calculated as the product of the applied load and the distance between the point of rotation and the line of action of the force. Next, you will need to determine the moment of inertia of the steel angle. The moment of inertia measures the resistance of an object to changes in its rotational motion. It depends on the shape and size of the object. In the case of a steel angle, the moment of inertia can be calculated using the appropriate formula for the specific cross-sectional shape of the angle. Once you have determined the bending moment and the moment of inertia, you can calculate the bending stress using the formula: Bending Stress = (Bending Moment * Distance from Neutral Axis) / Moment of Inertia The bending stress represents the internal resistance within the steel angle to the bending moment. It is typically expressed in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (Pa). It is important to note that the calculation of bending stress assumes that the steel angle behaves elastically, meaning it is not subjected to excessive deformation or permanent damage. If the applied bending moment exceeds the elastic limit of the steel angle, plastic deformation or failure may occur, and a different analysis method would be required.

- Q: What is the purpose of using steel angles in construction?

- Steel angles serve various purposes in construction. Their primary function is to offer structural support and stability to different components of a building or structure. Reinforcing corners, edges, and joints, these angles enhance the overall strength and rigidity of the structure. Moreover, steel angles play a crucial role in distributing and transferring loads or forces within the construction. They facilitate the even distribution of weight and stress across various parts of the structure, preventing the formation of weak points. Furthermore, steel angles are highly versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, seamlessly integrating into a wide range of construction projects. Not only that, but steel angles also exhibit remarkable durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With the ability to withstand heavy loads and extreme weather conditions, they provide long-lasting support to the structure. In conclusion, the utilization of steel angles in construction aims to enhance structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: Can steel angles be used for stairs in industrial settings?

- Yes, steel angles can be used for stairs in industrial settings. Steel angles are commonly used in industrial construction due to their strength, durability, and ability to support heavy loads. They provide structural support and stability, making them suitable for staircases in industrial settings where safety and reliability are crucial.

- Q: What are the different methods for protecting steel angles from corrosion?

- There are several methods available for protecting steel angles from corrosion. 1. Galvanization: Galvanization is a widely used method where a layer of zinc is applied to the surface of the steel angle. This zinc layer acts as a sacrificial anode, meaning it corrodes first before the steel, protecting it from rust. This method provides excellent protection and is commonly used in outdoor applications such as construction and infrastructure. 2. Paint coating: Applying a paint coating to the steel angle can provide an effective barrier against corrosion. The paint forms a protective layer that prevents moisture and oxygen from reaching the steel surface, thus inhibiting the corrosion process. It is important to use high-quality, corrosion-resistant paints for long-term protection. 3. Powder coating: Powder coating involves applying a dry powder to the steel angle which is then cured at high temperatures. This creates a hard, durable, and protective layer on the surface. Powder coating provides an attractive finish and excellent resistance to corrosion, making it suitable for both indoor and outdoor applications. 4. Stainless steel: Using stainless steel angles is another method for protecting against corrosion. Stainless steel contains chromium, which forms a passive oxide layer on the surface that acts as a protective barrier against corrosion. This makes stainless steel highly resistant to rust, making it ideal for applications where corrosion is a concern. 5. Cathodic protection: Cathodic protection is a technique used to protect steel angles by making them the cathode in a corrosion cell. This is achieved by connecting the steel angle to a sacrificial anode, such as zinc or aluminum, or by using impressed current systems. By doing so, the anode corrodes instead of the steel, effectively protecting it from corrosion. It is worth noting that the selection of the appropriate method for protecting steel angles from corrosion depends on various factors such as the intended application, environmental conditions, and budget constraints. Consulting with corrosion experts and considering the specific requirements of the project is advisable to ensure the most suitable method is chosen.

- Q: Are steel angles available in custom sizes?

- Yes, steel angles are available in custom sizes.

- Q: Are steel angles suitable for earthquake-prone areas?

- Due to their exceptional structural properties, steel angles find widespread use in construction, especially in areas prone to earthquakes. The L-shaped configuration of steel angles imparts significant stability and strength, rendering them ideal for withstanding seismic forces. Renowned for their high tensile strength and resistance to bending and twisting, steel angles play a vital role in earthquake situations. Moreover, steel is a ductile material capable of undergoing substantial deformation without failing, thereby absorbing a portion of the seismic energy generated. This flexibility effectively prevents catastrophic structural collapse during earthquakes. Additionally, steel angles can be easily fastened together through bolting or welding, ensuring efficient and cost-effective construction processes. Nonetheless, it is crucial to emphasize that the design and construction of structures in earthquake-prone areas must adhere to local building codes and regulations to guarantee maximum safety.

Send your message to us

Unequal Angle Steel Factory Price Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords