Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

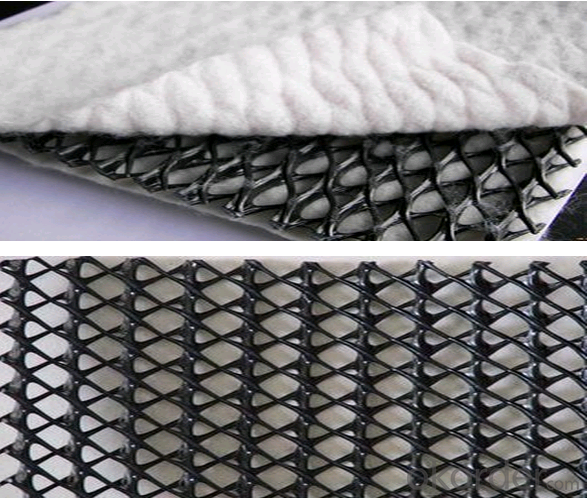

Tri-dimension composite genet for drainage is a new type of geosynthetics.

Its made of atri-dimension geonet coated with geotextile on both sides. Network core consists of a tri-dimension

thick vertical rib, and a rip on top and bottom .

It can drain underground water quickly, also there is a protection system,which can block the capillary water under high load. At the same time, it can also reinforce and isolate of foundation.

Product Uses

1,Landfill drainage;

2, Roadbed and road drainage;

3,Railway drainage, tunnel drainage, underground structure drainage.

4,The retaining back wall drainage,

5,gardens and sports grounds drainage

Functions

Excellent drainage function, can bear long time hige press load

High tensile and shear strength

Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

Tri-dimension composite geonet for drainage can bear more than kpa compression load

Its anti-compression capacity is much larger than common geonet for drainage.

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geomembranes be used in stormwater detention systems?

- Yes, geomembranes can be used in stormwater detention systems. Geomembranes are impermeable liners that can effectively contain and manage stormwater runoff, preventing it from infiltrating the ground. They can be used to line detention ponds, basins, and other stormwater management structures, helping to reduce flood risks and control water flow.

- Q: What is the composite geomembrane, how to define it?

- It's the combination of geotextile and geomembrane, there are two fabrics and one membrane and one fabrics and one membrane,

- Q: What are the advantages of eletromembrane floor heating?

- 1, green and environmental protection, no environmental pollution electrothermal film heating system will not produce soot and dust, which is more in line with the requirements of urban planning, very suitable for the requirements of going green and environmental protection in modern society. 2, warm like the natural sunlight due to the electrothermal?film heating system use radiation mode to supply heating, it can bring people warm and comfortable feeling like bathing in the sunlight. Which will not produce dry and hot feeling like that produced by traditional heating system. 3, low temperature operation, safe and reliable The electrothermal film surface will keep running in low temperature during work and the highest temperature will not exceed 60 degrees Celsius, so scald, explosion and fire will not happen. The whole system is connected through parallel mode, running very stable and with high feasibility. 4, can be charged according to households As electrothermal?film heating system can sdapy to the needs of a variety of users, so it can be measured according to households, units or floors, etc., which enable users to control the electricity consumption freely.

- Q: What is the method of sticking membrane on cabinet?

- First, clean cabinet surface. It is recommended to use medical alcohol with 75% concentration, which is easy to clean and dry. Measure the length, width and height to stick with tape, then cut on the purchased membrane. To avoid waste, you'd better draw on draft paper. Finally, stick from top-down, and stick right bit by bit, or it would be difficult to handle if you find slanting in the end.

- Q: What is the role of the base film

- Best to use a base film, if the direct wallpaper paste, rubber adhesive is very strong, it is possible to directly attached to the wall of the grass roots to pull off, if you brush a layer of the base film (also called wallpaper partner), the base film can close wall, waterproof, increase adhesion of the walls and wallpaper, brush one day after the wallpaper, etc., no problem

- Q: How do geomembranes contribute to erosion control?

- Geomembranes contribute to erosion control by providing a barrier between soil and water. They prevent water from seeping into the ground, thereby reducing the potential for erosion caused by water runoff. Additionally, geomembranes can be used to line channels and slopes, preventing soil displacement and erosion.

- Q: What's the question need to notice about the construction method of composite geo-membrane?

- 1, construction preparation: 1) composite geomembrane materials quality testing, this project used composite geomembrane is two cloths film one film composite geo-membrane, 2) clean up embankment slope, flat ground, remove all sharp corner sundries, backfill and tamppile the slope is qualified acceptance after supervisor, providing working surface for the pavement of composite geo-membrane. 3) as for geomembrane split joint, for the sake of convenient construction, ensure the quality of split joint, composite geomembrane should as far as possible use wide range, decrease the field splice quantity , before construction, in accordance with the requirements of composite geomembrane width and scene length demands, it should be cut inside the unit, and spliced into the required size block, to roll it on the steel pipe, manual handling it to the working face. 2, 1) composite geomembrane pavement, 1) the laying method of composite geomembrane, compound geomembrane pavement is divided into paving of canal bed and slope paving two parts. Paving method: rolly paving it in axis direction of canal. slope paving, after qualified acceptance of slope, roll along the axis of the slope, and connect to composite geo-membrane in T-shape. 2) composite geo-membrane's pavement should be processed in dry and warm weather, in order to be convenient for split joint, prevent stress concentration, compound geomembrane pavement should take the wavy relaxation method, surplus degrees is about 1.5%, timely pull away after being open, and it requires that the composite geomembrane should be flat and smooth with slope surface, without ridges fold, construction personnel should wear flat soft cloth shoes or rubber shoes, it is forbidden to wear cleats, lest trampled geomembrane, if geomembrane is destroyed during construction, it should be repaired in a timely manner. 3) composite geo-membrane's split joint.

- Q: Can composite geo-membrane be used for roof waterproof?

- Geomembrane? Do you refer to geotextile? Main material can be made of polyvinyl chloride PVC waterproof roll and geotextile, stuck by special adhesive powder.

- Q: How do geomembranes contribute to dam construction?

- Geomembranes are essential in dam construction as they act as impermeable barriers that prevent water seepage. By lining the reservoir and foundation of a dam, geomembranes ensure the stability and integrity of the structure, reducing the risk of leakage and potential failure. Additionally, geomembranes help in managing water resources by minimizing water loss due to seepage, making them a vital component in the construction and maintenance of dams.

- Q: Is it necessary to stick film for ipad?

- No, it is not necessary. You had better to stick film so that your ipad will be not easily scratched. The film basically has three kinds: 1. The HD and transparent film looks like no film. When you are calling, your phone will close to your face and you will feel a bit greasy. 2. The frosted film looks like a bit fuzzy, but does not affect the use. At the first, you may be not accustomed, but after a long time, you will be accustomed. The biggest difference between this film and high-definition film is that it is dry, and you won't feel greasy when you touch it. 3. Diamond film There is some so-called sparkled diamond fragments in it. But whether there is diamond fragment, has not been studied. It is the same as high-definition film, feeling a bit greasy.

Send your message to us

Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords