Tower Crane TC6024 Construction Equipment Sales Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tower Crane TC6024 Details:

Minimum Order Quantity: 1unit Unit: unit Loading Port: China main Port

Supply Capability: 5unit/month Payment Terms: T/T or L/C

Tower Crane TC6024 Description:

1.CMAX Tower Crane TC6024 is one of the main product of CNBM company, which have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2. Tower Crane TC6024 can adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected.

3. Tower Crane TC6024has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

4.Tower Crane TC6024 has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter,weightlimiter,circumgyrating limiter,and so on.

5.Tower Crane TC6024 has scientific layout and beautiful appearance. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operato.

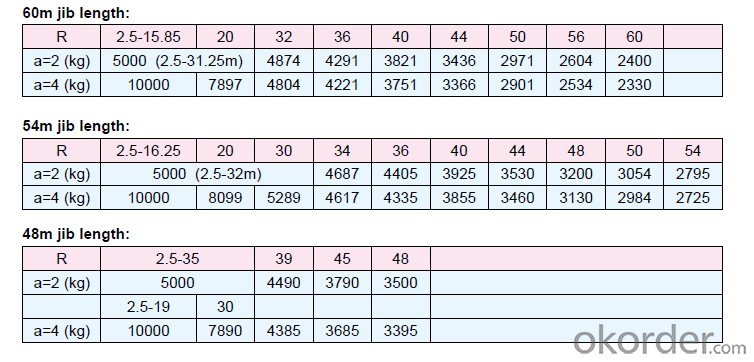

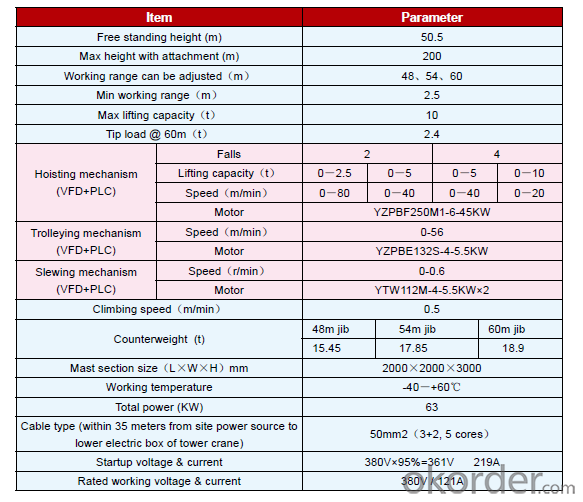

Tower Crane TC6024 Parameter:

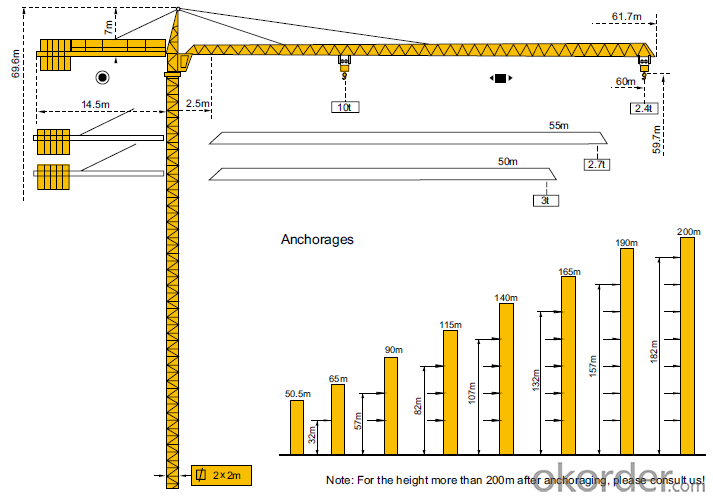

Max. working range 60m, tip lifting weight 2.4T and Max. lifting weight 10T.

Hoisting mechanism fitted with three speed motor, stable braking and less shock when shifting.

Trolleying mechanism can provide two operation speeds.

Free standing height (m) 50.5

Max height with attachment (m) 200

Working range can be adjusted (m) 48、54、60

Min working range (m) 2.5

Max lifting capacity (t) 10

Tip load @ 50m (t) 2.4

Tower Crane TC6024 Packaging & Delivery:

40HQ container

20~25days after deposit

Tower Crane TC024 Diagram:

\ \

\

Tower Crane TC6024 Technical Sheet:

Tower Crane TC6024 FAQ:

1.What is tower crane?

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete foundation (and sometimes attached to the sides of structures as well), tower cranes often give the best combination of height and lifting capacity and are used in the construction site.

2. What is the meaning of the tower crane’s code?

Take Tower Crane TC6024 for example, the first two letters “TC” means Tower Crane, “60”means jib length is 60 meter, and the last two letter “24” means the tip load is :2.4 ton.

3. What is the principal to quote the right tower crane to the client?

First, we need to know clients’ requirements,for example, max lifting capacity, height, tip load and jib length.. Second, we need to know what the foundation requirement from the client is and Third if there are special needs. CNBM could suggest proposal according to clear data provided by the clients.

- Q: Who thinks William Shatner is adorable as Denny in Boston Legal? I do!! I just want to pinch his cheeks. He looks so lovable (in a chubby old guy kind of way. Lol.)AhahaAnd Shirley. She's so funny.Lincoln, suck. my. lobe. lol!Anywho...answer my denny question!!

- William Shatner made a huge leap in his career when he made fun of himself in Airplane! Pt II. He was so funny as Commander Murdoch of Lunar Station! Ever since then, Shatner has not shied away from playing a crazy old dude. Denny Crane is the archtype of looney old guy who still yearns for the ladies...all of them. I kinda know how he feels!

- Q: when a tall building is under construction you alwase see cranes on top. well i would like to know 1. how they move them up as the buildung gets taller and 2nd after there done how do they get them down?

- Larger cranes !!

- Q: I was watching house m.d. When I notice house walking with a crane I asked a friend who knows house and has seen it but dosent remember why and how. why is he?

- It's a cane not a crane. Whew! To summarize, what happened to House's leg was that there was muscle death of the leg. He should have had it amputated, but he didn't. Instead, he wound up with a nearly useless, and chronically painful leg. Stacy, as a participant in this demise, well, I guess the relationship was all downhill from there. House realizes it was all his fault. If he would have just got the amputation, he wouldn't have screwed it all up Stacy is his ex-wife.

- Q: do they get the concrete blocks up that hang at the end? Do they use another type of crane to assemble them?

- Tower cranes assembly starts with the foundation of the crane with lot concrete blocks for fixing, then they fix the first bottom part of the crane then they fix the boom with the counter weights, when they want to extend the height, they fix a jack up machine which lift up the boom and then insert a vertical piece and so on till they reach the required height. During the first installation they use a small mobile crane and then after the crane it self lift and fix the pieces

- Q: Do some schools of hung gar only teach (or focus on) the tiger crane form?

- I don't think so, not if it is taught as a complete system, then it should offer more than just tiger/crane form.

- Q: They're so big

- They rebuild them on side piece by piece.

- Q: across the street from my work, there are three big cranes. It seems like they just popped up over night. anyone know how they get them built?

- I okorder you may find an article mate

- Q: What kind of force acting in the brake system which encounter the lifting material force and to maintain its level.

- Cranes work using hydraulics and cables. The cables are wrapped around pulleys and the pulley is turned using hydraulic power. The brake system is simply stopping the pulley from turning by reducing power. The hydraulic system typically will turn a series of gears which in turn spins the pulley that the cable is wrapped around. It's different than a brake system say on a car where when you hit the brakes, pads squeeze on the interior of the wheel rim slowing it down. Cranes you just reduce power and stop the pulley from turning. They also have emergency stops. Older cranes have wedges that would be released onto the cable and then the wedges would grab the cable and slip into a ring. The narrow end of the wedges would slip into the ring first and then as the wedges increased in diameter the grip on the cable would get tighter and then stop the cable from moving. They also have systems on the pulleys to stop the pulley from spinning. They essentially work the same way as a car break. When the emergency brake is triggered, pads will squeeze on the rim of the pulley to stop it. These mechanisms work by friction. They could also have holes around the pulley and a steel pin would be pushed into one of the holes to stop it from spinning. Of course if the force of the weight exceeded the strength of the pin, it would shear.

- Q: Two cranes are lifting identical steel beams at the time.One crane is putting out twice as much power as the other assuming friction is neglible, what can you conclude is happening to explain this difference?

- One crane is lifting the beam twice as fast as the other. The amount of energy required (work done, in Joules) to lift a mass m through a distance h against gravitational acceleration g is simply W=mgh. But power is the -rate- at which energy is used (or work is done in Joules/sec). So a crane that is twice as powerful should be raising the beam twice as quickly. Doug

- Q: In Catching Fire Katniss hangs a dummy with the words Seneca Crane on it. Who is that? It sounds familiar...

- okay, i was just wondering the same thing! seneca crane is the previous head gamemaker that didnt kill katniss peeta after the 'berry' incident. u can refer back to page 20 in chapter 2! go ahead check it out. okay, gotta go do some more reading!

Send your message to us

Tower Crane TC6024 Construction Equipment Sales Building Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords