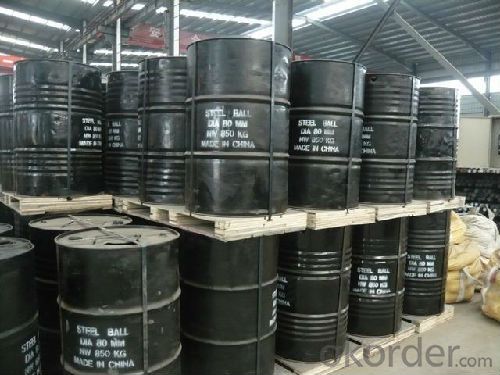

Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Appearance Quality of Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

Surface smooth,no crack, visible gas hole, slag inclusion,shrink-looseness, cold lap, wrinkled skin and other obvious casting defect.

Features of Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

1.Superfine wear-resistant (Martensite). Best suitable for cement building material.

2. Good toughness , durable and broken less

3 Products through high temperature quenching, have good uniformity of surface hardness and lower circle loss rate.

Chemical composition of Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

C | Mn | Si | Cr | Mo | S | P | |||||

Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Max | Max |

0.52 | 0.85 | 0.60 | 1.10 | 0.17 | 0.37 | 0.05 | 0.25 | 0.00 | 0.04 | 0.04 | 0.035 |

Hardness of Grinding Ball of Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

DIA25MM-DIA110MM | DIA125MM-DIA150MM | |

Superficial | 55HRC-65HRC | 53HRC-63HRC |

Volumetric | 55HRC-65HRC | 53HRC-63HRC |

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: How to cast iron and wrought iron collocation

- So we can only watch and ear distinction: 1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron pig iron is bright; the fracture is generally irregular, because it is very brittle, mostly is interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat; if the fracture is that is cutting, wrought iron, iron is not cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity It doesn't have to be so deformed, it's really bent, or it's broken, or it's obviously cracked, and it doesn't bend very much. There are some details that can not be made clear. It is necessary to have some experience.

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: What are the general technical requirements for casting parts?

- Satisfy appearance quality (appearance defect, quality change, size deviation)Intrinsic quality (composition, properties, internal organization)Service performance (abrasion resistance, corrosion resistance, heat resistance, pressure resistance)

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

1. Manufacturer Overview

| Location | Anshan City, Liaoning Province,China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Domestic Market; South America; Eastern Asia; South Asia; Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port;Dalian Port;Tianjin Port;Yingkou Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 24,400 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | grinding ball,grinding media,casting ball,casting grinding ball |

| Product Price Range | Average |

Send your message to us

Top Rank High Carbon Forged Grinding Ball for Mining Millinggrinding Ball for Gold Mine for Cement Plant

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords