Top Quality PPR Female Threaded Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

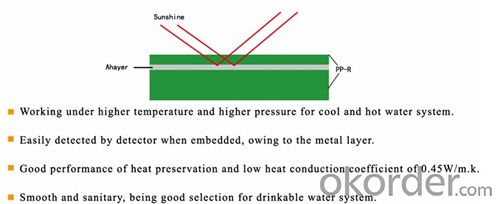

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Advantages and disadvantages of PPR pipes

The full name of PP-R pipes with an international level of new energy-saving plastic products in the nineties is the random copolymer polypropylene piping. PPR installation and use of the advantages and disadvantages are as follows:

Advantages:

1. Harmless to human health, to all ions in water and chemicals in the building are no chemical reaction, compared with metal pipes do not rust, plastic water pipe will not corrode, and has a high degree of acid resistance and chloride resistance.

2. Belonging to the sustainable development green products. There is no environmental pollution in the process of production, construction and use. Secondary recovery can be repeatedly used.

3. Are different, homogeneous melt PP-R pipe is connected with other pipeline is the biggest advantage of this pipe system. Pipe connections disclose rate is very low, no maintenance, usable visual inspection, the joint firm could no corrode.

4. Light weight, easy handling construction, can greatly reduce the labor intensity, fast construction progress.

5. Good heat resistance: instant use temperature can reach 95 degrees. Long-term use at work pressure does not exceed 0.6Mpa, temperature up to 70 degrees. To meet the general needs of life and production of hot water, it is an ideal hot water pipe.

6. Low thermal conductivity: thermal conductivity of 20 degrees was 0.23 ~ 0.24W / Mk, much smaller than steel and copper. Used in air conditioning or hot water supply and drainage, you can save the investment in the pipeline insulation.

7. Elastic modulus is small: stress due to temperature change is small, suitable for direct burial, in-wall and floor surface layer Concealed way. With High-grade appearance, it is a trend of fashion.

8. Small pipe resistance: pipe wall smooth, non-furring, small head loss, head loss is smaller than the metal pipe; the local head loss is also smaller than the metal tube.

9. Performance can be repaired pipeline: full advantage of PP-R pipe hot melt, the use of PP-R of the eye of a needle stick fill holes in the pipeline repair can also be cut out the damaged pipe replacement pipe.

Disadvantages:

1. Higher cost: With the continuous promotion of the pipe is now ready to accept the price, but the price is still too high, pipe fittings, because one mold imports; Second, copper and stainless steel fittings materials pipe fittings are used in special requests these metals temperature coefficient and accessories for a temperature coefficient of PP-R materials strict consensus, now also need foreign imports.

2. PPR size is only a small outer diameter of 20-110 mm diameter products; types of fittings and valves missing, there is connected to the metal valves inconvenient questions.

3. Rigidity and impact resistance worse than metal pipes.

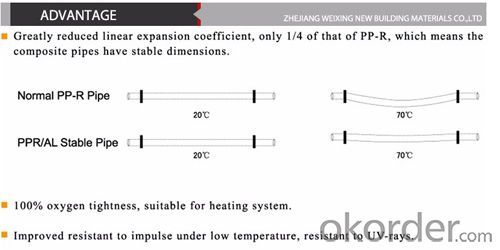

4. Larger coefficient of linear expansion, for surface or overhead required to lay more pipe hangers, affect the appearance.

5. Construction equipment advanced complex, construction technology requirements, construction workers and construction quality management requirements high. Joint quality and temperature of the hot melt connection, heating time, the seam stress-related, construction prone to bias.

6. UV resistance is poor, in the long sunlight easy to aging.

7. PP-R pipe belonging to combustible materials, it cannot be used for fire water supply system.

- Q: Where do I find a metal magazine tube follower for a remington 1187?? All i can find are plastic!!!?

- I have a metal tube extension for my 870 and IMO its amazing and I never anything wrong at all.

- Q: How about plastic pipes for water pipes in the house? With PVC or PPR or something?

- By using the technology of melting PPR pipe interface between the tubes completely fused together, so once installed by the pressure test, not as long as there are aluminum pipe and PPR pipe Water Leakage aging phenomenon, will not scale. PPR water here suggested that the landlord like buy Suyou pipe industry like this brand, this is my home with the pipe, the quality is still very good, not on the crook of the road, to the regular place to buy a good product, which can ensure that the buy is genuine, as for how to distinguish true or false

- Q: it is too short as it allows water backup from my discharge pipe. does anyone have any idea's how I can extend my gooseneck deeper into my discharge pipe so water does not back up?and no, I do not have a blockage. my plumber told me my washer discharge gooseneck is too short. it needs to go 8 to a foot into pipe.

- Normally the plastic part that forms the n shaped bend can be unclipped and moved up the hose so you can get a longer length into the discharge stand pipe. If the pipe is too short to reach the stand pipe when you do this, you can buy an extension kit from a hardware store.

- Q: Do plastic tubes have any limitations in terms of shelf life?

- Yes, plastic tubes do have limitations in terms of shelf life. Over time, plastic tubes can degrade, become brittle, or lose their flexibility, which affects their overall functionality and durability. Additionally, exposure to certain environmental factors like heat, sunlight, and chemicals can accelerate this degradation process, further reducing their shelf life. It is important to consider these limitations when storing or using plastic tubes to ensure their effectiveness and longevity.

- Q: What are the advantages of using plastic tubes in the marine packaging industry?

- There are several advantages of using plastic tubes in the marine packaging industry. Firstly, plastic tubes are lightweight, making them easy to transport and handle, which is crucial in the marine industry where weight and space are often limited. Additionally, plastic tubes are highly durable and resistant to water, moisture, and other environmental factors, making them ideal for protecting products in a marine environment. Plastic tubes also offer excellent barrier properties, ensuring the preservation and integrity of the packaged goods. Furthermore, plastic tubes can be customized with various closures, such as screw caps or flip-top lids, offering convenience and ease of use for both manufacturers and consumers. Lastly, plastic tubes are versatile and can be easily shaped, colored, or printed on, allowing for branding and product differentiation opportunities in the competitive marine packaging industry.

- Q: How are plastic tubes affected by temperature changes?

- Plastic tubes are affected by temperature changes as they can expand or contract depending on the temperature. This can lead to changes in their dimensions, which may cause them to become loose or tight fitting in certain applications. Additionally, extreme temperature variations can make plastic tubes more susceptible to cracking or breaking under stress.

- Q: Rescue fish, currently in temporay home 20 gal 70' filtered oxygenated tank until I can get another tommorow. But he looks stressed, I think he needs a place to hide for the night, and the PVC I have at the moment is too light to sink. I found the plastic in the basement of the older home we live in, good size for him, but I am worried that plastic of an uncertain age might give off some kind of toxin/poison. Can anybody help? Suggestions for alternatives welcome...

- That's the old ABS plastic. It's not used much anymore because of problems with building codes. It's no more toxic than PVC. until a house fire starts it to burn. Stay away from old joints with cement, sterilize as you would with any other ornament and you'll be fine. You can also still buy it new.

- Q: I make models and the plastic that winds up in the trash could be reused if only I knew how to glue it. I have tried all of mine (401, epoxy, Loctite, Gorilla Glue, etc) to no avail.

- I use E-6000 clear glue for almost everything. I am a sewer and needed some weights so I used this glue on huge metal washers putting two of them together for more weight. I have had these weights for quite a few years. The trick to this glue is to let is set. According to the label is it flexible, paintable, non-flammable, waterproof, safe for photographs, etc. I would suggest not using this in an enclosed area for any length of time. Good luck - Hope that helps.

- Q: Can plastic tubes be used for greenhouse construction?

- Yes, plastic tubes can be used for greenhouse construction. They are often used as a cost-effective alternative to traditional materials such as metal or wood. Plastic tubes are lightweight, easy to handle, and resistant to weather and corrosion, making them suitable for greenhouse structures. Additionally, their flexibility allows for creative designs and easy installation.

- Q: How are toothpaste tubes made? I know that there's polyethylene coatings on aluminum, but how to they actually made the tubes this way? I know it can't be injection molding or blow molding.

- why can't it be injected extrusion molding of the tubing followed by a bonding process?

Send your message to us

Top Quality PPR Female Threaded Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords