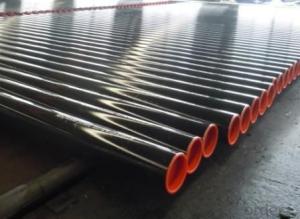

Thin Wall welded Stainless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Outer diamete :6-90

Wall thickness:0.16-2.5

Material:201,304,201L,304L

Surface:Polih/hairline

Technics:Cold rolled

Product Description

| type | Thin Wall Thicknes Welded stainless steel tube |

| Materil | 201,304 |

| Application | Decoration,Bathroom… |

| specification | Outer diamete : 19*19-50*50 Wall thickness:0.16-2.5 |

| Length | 6m(as required) |

| surface | Polish/hairline(as required) |

| technics | Cold rolled |

- Q: Can stainless steel pipes be used for desalination systems?

- Yes, stainless steel pipes can be used for desalination systems. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions involved in desalination processes, such as high salinity and the presence of chemicals. Its durability and resistance to corrosion make it an ideal material choice for transporting and distributing desalinated water.

- Q: What is the difference between 316 and 316Ti stainless steel pipes?

- The main difference between 316 and 316Ti stainless steel pipes is the addition of titanium (Ti) in 316Ti. This titanium content makes 316Ti more resistant to corrosion and sensitization at elevated temperatures, making it suitable for applications where the pipes will be exposed to high temperatures. 316 stainless steel, on the other hand, does not contain titanium and is more commonly used for general-purpose applications.

- Q: What are the specifications for stainless steel pipes?

- The specifications for stainless steel pipes typically include the material grade, dimensions (such as outer diameter, wall thickness, and length), and specific standards or certifications they adhere to, such as ASTM, ASME, or EN. Additionally, specifications may also include information about the surface finish, type of joint or connection, and any special requirements for corrosion resistance or mechanical properties.

- Q: Are stainless steel pipes suitable for heat exchangers?

- Yes, stainless steel pipes are suitable for heat exchangers. Stainless steel possesses excellent heat transfer properties and is resistant to corrosion and oxidation, making it an ideal material for heat exchanger applications. Its durability, high strength, and ability to withstand extreme temperatures make stainless steel pipes a reliable choice for efficient heat exchange.

- Q: What's the difference between stainless steel pipe and stainless steel composite pipe?

- The stainless steel composite pipe is iron pipe. The outside is plated with stainless steel. It is heavy, but it is easy to rust for a long time,

- Q: How do you determine the size of a stainless steel pipe?

- To ascertain the dimensions of a stainless steel pipe, several crucial factors must be taken into account. First and foremost, the outside diameter (OD) of the pipe needs to be measured. This can be achieved by employing either a caliper or a tape measure. It is imperative to ensure that the measurement is taken across the widest point of the pipe in order to obtain an accurate reading. Following that, the wall thickness of the pipe should be determined. This can be accomplished by employing a caliper or a pipe gauge. The wall thickness plays a pivotal role in determining the pipe's strength and durability. Once the measurements for the OD and wall thickness are obtained, one can proceed to calculate the nominal pipe size (NPS) or the trade size of the stainless steel pipe. This measurement is typically expressed in inches and denotes the inner diameter (ID) of the pipe. Industry standards or pipe size charts available online can be utilized to determine the NPS. It is worth noting that stainless steel pipes are commonly available in various schedules, which indicate the varying wall thicknesses. These schedules range from Schedule 5S (the thinnest) to Schedule XXS (the thickest). The pipe's schedule should be taken into consideration when determining its size as it impacts the pipe's pressure rating and suitability for specific applications. In summary, determining the size of a stainless steel pipe involves measuring the outside diameter, determining the wall thickness, and calculating the nominal pipe size based on industry standards or pipe size charts.

- Q: Can stainless steel pipes be insulated with polysulfone?

- Insulation of stainless steel pipes with polysulfone is indeed possible. Polysulfone, a highly durable and heat-resistant material commonly used for insulation, is suitable for this purpose. It possesses excellent thermal insulation properties, making it ideal for insulating stainless steel pipes in various applications. Moreover, polysulfone exhibits resistance to chemicals, making it a suitable choice for environments where corrosion or chemical exposure is a concern. However, it is crucial to ensure that the polysulfone insulation meets the specific requirements and temperatures of the stainless steel pipes being insulated. Seeking advice from a professional or referring to the manufacturer's guidelines can aid in determining the suitability of using polysulfone insulation for stainless steel pipes in a particular application.

- Q: What are the common corrosion issues with stainless steel pipes?

- The common corrosion issues with stainless steel pipes include pitting corrosion, crevice corrosion, and stress corrosion cracking. Pitting corrosion occurs in localized areas, leading to the formation of small pits on the pipe surface. Crevice corrosion occurs in gaps or crevices, such as at pipe joints or under deposits, leading to localized corrosion. Stress corrosion cracking is a form of corrosion caused by a combination of tensile stress and a corrosive environment, resulting in cracking of the pipe.

- Q: What is the difference between seamless and EFW stainless steel pipes?

- Seamless and EFW (Electric Fusion Welded) stainless steel pipes are two different types of stainless steel pipes that have distinct characteristics and manufacturing processes. Firstly, seamless stainless steel pipes are manufactured without any welding seams or joints. They are made from a solid cylindrical billet, which is heated and then stretched over a mandrel to create a hollow tube. This process ensures that seamless pipes have a consistent wall thickness and a smooth interior surface, making them ideal for applications that require high-pressure, high-temperature, or corrosive environments. Due to their seamless construction, these pipes offer better strength and durability. On the other hand, EFW stainless steel pipes are created by using a combination of high-frequency electrical current and pressure to weld the edges of two stainless steel sheets or plates together. This fusion welding process forms a continuous seam along the length of the pipe. EFW pipes are typically used for lower-pressure and lower-temperature applications, such as conveying fluids or gases in industrial settings. One key difference between seamless and EFW stainless steel pipes is their manufacturing complexity. Seamless pipes require more intricate and precise manufacturing techniques, resulting in a higher production cost compared to EFW pipes. Additionally, the seamless process allows for a wider range of sizes and thicknesses, while EFW pipes are typically limited in their size options. Another difference lies in the availability of grades and alloys. Seamless stainless steel pipes are available in a wide range of grades and alloys, offering greater flexibility for specific applications. EFW pipes, on the other hand, have a more limited selection of available grades and alloys. In terms of mechanical properties, seamless stainless steel pipes generally have superior strength and corrosion resistance compared to EFW pipes. The absence of welds or joints in seamless pipes reduces the risk of weak points that could be prone to corrosion or failure. In summary, seamless stainless steel pipes are manufactured without any welding seams, offering better strength, durability, and corrosion resistance. They are suitable for high-pressure, high-temperature, or corrosive applications. EFW stainless steel pipes, on the other hand, are created by fusion welding two stainless steel sheets or plates together, making them more suitable for lower-pressure and lower-temperature applications.

- Q: Are stainless steel pipes resistant to pitting and crevice corrosion?

- Yes, stainless steel pipes are generally resistant to pitting and crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface, preventing corrosion. However, the resistance can vary depending on the specific grade of stainless steel and the environment in which the pipes are used.

Send your message to us

Thin Wall welded Stainless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords