Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification of large diameter longitudinal submerged arc welded pipe:

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Grade:API 5L GR.B, X40, X42, X52, X56, X60, X65, X70.ST37/37-2,ST33,ST35.8,ST35.4.GB 9711.1/SY5037/GB3092

3)Standard:ASTM A53,ASTM A671 ,ASTM A672 .ASTM A252 API 5L (PSL-1,PSL-2) ,API 5L 2B ,2H,2W.DIN1626,DIN17175,DIN1629.JISG 3452,JISG3457/3456,JISG3461.GB 9711.1/SY5037/GB3092

2.Size of large diameter longitudinal submerged arc welded pipe:

OD: 406.4MM-1422MM (16”-56”)

Thickness: 8MM-50.8MM depends on OD

3.Data Sheet for large diameter longitudinal submerged arc welded pipe:

Standard: APISPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

| Min | Max | Min | Max | |

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 | 517 | 758 | |

×65 | 448 | 600 | 531 | 758 | |

×70 | 483 | 621 | 565 | 758 | |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S | CEV |

Max | Max | Max | Max | Max | ||

PSL1 |

- | |||||

B | 0.26 | 1.2 | 0.030 | 0.030 | ||

×42 | 0.26 | 1.3 | 0.030 | 0.030 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | ||

PSL2 |

0.43 | |||||

B | 0.22 | 1.20 | 0.025 | 0.015 | ||

×42 | 0.22 | 1.30 | 0.025 | 0.015 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | ||

4. Packing & Delivery

Packing Detail: bundles with anti-rust painting and with plastic caps

Delivery Term: 30 days after receving payment or L/C

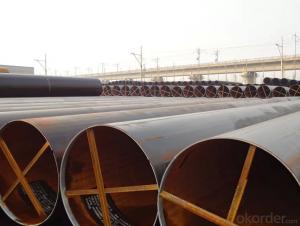

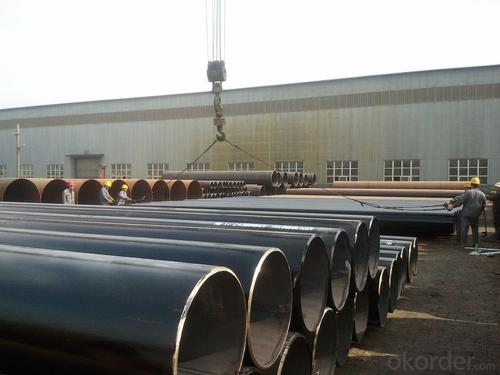

5. Products picture for large diameter longitudinal submerged arc welded pipe:

6. FAQ of large diameter longitudinal submerged arc welded pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

- Q: What are the safety precautions to follow while working with steel pipes?

- When working with steel pipes, it is important to follow certain safety precautions to ensure a safe working environment. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, steel-toed boots, and a hard hat. This will protect you from potential hazards such as falling objects, sharp edges, or flying particles. 2. Use proper lifting techniques: Steel pipes can be heavy and awkward to handle. Use proper lifting techniques, such as bending your knees and using your legs to lift, to avoid straining your back or causing musculoskeletal injuries. 3. Secure the work area: Clear the work area of any clutter or obstacles that could pose a tripping hazard. Ensure that the pipes are properly stored and secured to prevent them from rolling or falling. 4. Be cautious of sharp edges: Steel pipes often have sharp edges, which can cause cuts or punctures. Handle them with care and consider using protective covers or gloves to avoid injuries. 5. Use appropriate tools: Utilize the correct tools and equipment for cutting, welding, or manipulating steel pipes. Follow manufacturer instructions and guidelines to ensure safe usage. 6. Avoid working in confined spaces: Working in confined spaces poses serious risks. If it is necessary to work in such an area, ensure proper ventilation and follow confined space entry protocols to prevent asphyxiation or other hazards. 7. Follow proper welding procedures: If welding is involved, follow proper welding procedures and ensure proper ventilation in the workspace. Use fire-resistant blankets or screens to protect nearby combustible materials. 8. Be aware of hot surfaces: Steel pipes can become hot during welding or other processes. Use appropriate insulation or heat-resistant gloves to protect yourself from burns or heat-related injuries. 9. Establish communication: Establish clear communication channels with colleagues when working with steel pipes, especially when lifting or moving heavy objects. Use hand signals or verbal communication to ensure everyone is on the same page and to prevent accidents. 10. Regularly inspect tools and equipment: Before starting any task, inspect tools, equipment, and scaffolding for any damage or defects. Report and replace any faulty equipment to prevent accidents. Remember, safety is paramount when working with steel pipes. By following these precautions and using common sense, you can ensure a safe working environment for yourself and your colleagues.

- Q: How are steel pipes used in the manufacturing of marine applications?

- Steel pipes are commonly used in the manufacturing of marine applications due to their durability and resistance to corrosion. They are used for various purposes such as constructing ship hulls, offshore platforms, and underwater pipelines. These pipes provide structural support and can withstand the harsh conditions of the marine environment, making them essential components in the manufacturing process of marine applications.

- Q: What are the common standards for coating and lining of steel pipes?

- Various organizations and regulatory bodies have outlined the common standards for coating and lining steel pipes to ensure their durability, corrosion resistance, and overall quality. These standards are widely recognized and utilized in different industries. Here are some examples: 1. The American Society for Testing and Materials (ASTM) has developed numerous standards for coating and lining steel pipes. For instance, ASTM A775/A775M addresses epoxy-coated reinforcing steel, ASTM A1064/A1064M focuses on metallic-coated steel wire, and ASTM A1057/A1057M covers fusion-bonded epoxy-coated steel reinforcement. 2. The American Water Works Association (AWWA) has established standards specifically for coating and lining steel pipes used in the water industry. AWWA C210 deals with liquid epoxy coating systems for both the interior and exterior of steel water pipelines, while AWWA C213 focuses on fusion-bonded epoxy coating for these pipelines. 3. The National Association of Corrosion Engineers (NACE) develops standards and recommended practices for corrosion control in steel pipes. NACE SP0169 provides guidelines for selecting and applying coatings for underground or submerged steel pipelines, and NACE SP0198 offers recommendations for external coatings of steel pipelines. 4. The International Organization for Standardization (ISO) has also developed various standards pertaining to coating and lining steel pipes. ISO 21809-1 specifies the requirements for external coatings applied to buried or submerged pipelines, while ISO 21809-2 concentrates on the internal coating and lining of such pipelines. These standards encompass multiple aspects of the coating and lining process, including surface preparation, application methods, minimum coating thickness, adhesion, and quality control. Adhering to these standards ensures that steel pipes receive proper protection against corrosion, abrasion, and other forms of deterioration. Consequently, they enjoy a longer service life and enhanced performance in industries such as oil and gas, water supply, and infrastructure.

- Q: What is the difference between internal lining and external coating of steel pipes?

- The internal lining of steel pipes refers to a protective layer or coating applied inside the pipe to prevent corrosion and to enhance the flow of fluids. This lining is typically made of materials like epoxy, cement mortar, or polyethylene, and it helps to reduce friction and resist the effects of chemicals or contaminants that may be present in the fluid being transported. On the other hand, the external coating of steel pipes is a layer or coating applied to the outside of the pipe to protect it from external factors like weather, soil, or mechanical damage. This coating is usually made of materials such as fusion-bonded epoxy, polyethylene, or polypropylene, and it acts as a barrier against corrosion, moisture, or abrasion. In summary, the internal lining of steel pipes focuses on protecting the pipe from the inside, while the external coating is intended to safeguard the pipe from external elements. Both the internal lining and external coating are essential for maintaining the integrity and longevity of steel pipes.

- Q: How are steel pipes insulated for thermal efficiency?

- Steel pipes are insulated for thermal efficiency using various methods such as applying insulation materials like fiberglass, mineral wool, or foam to the surface of the pipes. This insulation helps to prevent heat loss or gain, thereby improving the energy efficiency of the pipes. Additionally, protective outer layers such as aluminum or PVC jackets are often added for extra insulation and to provide resistance against moisture and external elements.

- Q: What is the weight of hot galvanized steel tubes? DN150 4mm wall thickness

- DN150 4mm wall thickness welded steel pipe theoretical weight is 16.21kg/m, galvanized steel pipe should be multiplied by the weight coefficient after galvanizing, C, DN150, wall thickness of 4mm, C=1.032, DN150, theoretical weight and wall thickness of 4mm galvanized steel is 1.02*16.21=16.7287kg/m = 16.73kg/m.

- Q: Can steel pipes be used for electrical conduit systems?

- Yes, steel pipes can be used for electrical conduit systems. Steel pipes are a popular choice for electrical conduit systems due to their durability and strength. They are capable of providing protection to electrical wires and cables from physical damage, moisture, and other environmental factors. Steel pipes also have high resistance to fire, making them suitable for installations in buildings where fire safety is a concern. However, it is important to note that steel pipes may require proper grounding to prevent electrical shocks and should comply with local building and electrical codes.

- Q: How do steel pipes handle thermal expansion?

- Steel pipes handle thermal expansion by expanding and contracting along their length due to changes in temperature. This expansion is accommodated by allowing the pipes to move freely or by using expansion joints, which can absorb the thermal expansion and prevent damage or failure.

- Q: Are steel pipes resistant to earthquakes?

- Steel pipes are generally considered to be more resistant to earthquakes compared to other materials such as concrete or PVC pipes. This is due to the inherent properties of steel, which include its high tensile strength and flexibility. During an earthquake, steel pipes can absorb and distribute the seismic energy more effectively, allowing them to better withstand the shaking and ground movements. Additionally, steel pipes have the ability to deform without rupturing or collapsing, minimizing the risk of structural failure. However, it is important to note that the earthquake resistance of steel pipes ultimately depends on various factors such as the design, installation, and overall structural integrity of the piping system. Proper engineering and construction practices should be followed to ensure the highest level of earthquake resistance for steel pipes.

- Q: What are the different types of steel pipe elbows?

- There are several different types of steel pipe elbows that are commonly used in various industries and applications. These types include: 1. 90-degree elbows: These elbows have a sharp 90-degree bend and are commonly used when a change in direction is required to redirect the flow of fluid or gas. They are widely used in plumbing, construction, and industrial piping systems. 2. 45-degree elbows: Similar to 90-degree elbows, 45-degree elbows also provide a change in direction but with a smaller angle. They are often used in situations where a more gradual change in flow direction is required. 3. Long radius elbows: Long radius elbows have a larger radius of curvature compared to standard elbows. This design helps to reduce fluid friction and pressure drop, making them suitable for applications that require smoother flow, such as in high-flow systems or those involving viscous fluids. 4. Short radius elbows: In contrast to long radius elbows, short radius elbows have a smaller radius of curvature. They are generally used in tight spaces where a compact design is required, but they can cause higher pressure drops due to increased fluid friction. 5. Reducing elbows: These elbows are used when there is a need to connect pipes of different diameters. They have one end with a larger diameter and the other end with a smaller diameter, allowing for a smooth transition between two pipes of different sizes. 6. Mitered elbows: Mitered elbows are custom-made elbows that are fabricated by cutting and welding multiple sections of pipe at specific angles. They are often used in situations where standard elbows cannot accommodate the required angle or when a unique design is needed. Overall, the selection of the appropriate type of steel pipe elbow depends on factors such as the application, fluid flow requirements, space constraints, and compatibility with the piping system.

Send your message to us

Large diameter longitudinal submerged arc welded pipe API

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords