The best-selling heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The best-selling heat-resistant glass in China

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

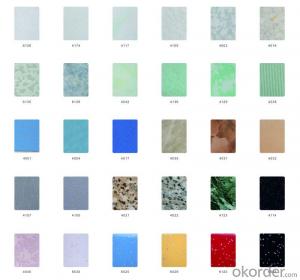

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at QIMINGXING Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- Figure, 1.5mm galvanized steel plate up and down. The middle of 100 thick fire rock wool.

- Q: Pipeline insulation materials, which are generally several types of fire protection

- Extruded board, rock wool, extruded board has B1, B2 level, the state is now not allowed to use B2 level, because the B2 level is not flame retardant, rock wool are generally A-level,

- Q: Insulation class fire rating non - combustible A - level and A2 - level difference

- A1 level is absolutely non-flammable and no smoke produced by the A2 non-combustible but there is a certain smoke poison gsy inorganic rigid foam insulation board details contact by registered name hit my cell phone

- Q: What is the fire insulation material

- Materials are: aluminum silicate fiber felt, inorganic mineral raw materials, perlite, glass fiber, ceramic fiber, mullite fiber, basalt fiber, high silicone fiber. Barrier insulation coating is a low thermal conductivity and high thermal resistance to achieve a thermal insulation coating. The most widely used barrier insulation insulation coating is a composite silicate insulation coating. This kind of coating is developed in the late 1980s, with different product names, such as composite magnesium aluminum silicate insulation coating, rare earth insulation coating, coated composite silicate insulation coating. It is made of inorganic and / or organic binder, insulation aggregate (such as sepiolite, vermiculite, perlite powder, etc.) and air entraining agent made of insulation coating. The performance requirements of such coatings can be found in GB / T-1998 "Silicate composite insulation coating". Composite silicate insulation coating Although the thermal conductivity is low, the cost is low, but the drying cycle is long, the impact resistance is weak, dry shrinkage, moisture absorption rate, low bond strength, poor decorative effect. This type of coating is currently used primarily for the casting of molds, tanks and pipes. This coating is currently not used for exterior insulation. In the future through the modified, is expected to be used for external wall insulation system.

- Q: Short point is to do hand copy

- Several common fire fighting methods: 1, furniture, bedding and other fire: the general use of water fire. With water around the items such as the basin and so on to the flame on the water, but also the water pipe connected to the faucet sprinkler fire; at the same time the burning point near the combustible humidification. But the oil, electrical fire can not use water to fire. 2, electrical fire: household appliances or lines on fire, we must first cut off the power, and then dry powder or gas fire extinguisher, can not directly splash water to prevent electric shock or electrical explosion wounding. 3, the TV fire: TV in case of fire, never water, you can cut off the power, with a quilt to cover it. Fire, only from the side close to the TV, to prevent the camera tube explosion wounding. If the use of fire extinguishers fire, should not be directed to the TV screen, so as to avoid the sudden cold after the heat and explosion. 4, the pan fire: the oil pan should quickly shut down the stove gas valve, directly cover the lid or cover with a wet cloth, but also to the pot put the chopped vegetables to cool the fire, the pot smooth from the fire, After cooling to open the lid, do not pour water to the oil pan. 5, gas tank fire: use wet bedding, clothing and other cover fire, and quickly close the valve. 6, the body of the fire, do not run around, can be used to roll or heavy clothing to suppress the flames. Wearing a wet towel, handkerchief and so cover your nose and mouth, try to make the body close to the ground, bending or creeping forward.

- Q: Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q: Fire protection requirements for indoor ceiling materials

- In the building interior design fire, the common parts of the common technical requirements. 1. Ceiling (ceiling) In all the interior decoration of the fire design, the ceiling fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. 1) single-layer, multi-storey civil building ceiling materials, generally should be non-combustible materials. The following buildings can be used in the construction of flame-retardant materials: ① construction area ≤ m2 of the station, the terminal waiting (boat) room, restaurants, shopping malls, etc .; 粻 open outline satin and other persuasion stitch ② each floor area < 1000m2 or the total area of ??<3000m2 shopping malls business hall; ③ no central air-conditioning system hotels, hotels, office buildings and complex buildings; 2) high-rise residential building ceiling materials in addition to two types of high-rise civil buildings can be used to build the ceiling of flame retardant materials, the other should be used non-flammable materials. 3) underground ceiling of civil buildings should be used non-flammable materials.

- Q: What is fireproof material? Fireproof material and insulation materials, refractory material is the same thing?

- Fireproof material is inorganic board, insulation material is organic board. Fireproof material can also be insulated, but no insulation material is good.

- Q: Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- The main detection capacity is not up to standard according to GB ah

- Q: Gypsum fire?

- Belong to a fireproof material.

Send your message to us

The best-selling heat resistant glass in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords