2015 Hot Sale Waterproof Masking Tape Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Describtion of 2015 Hot Sale Waterproof Masking Tape Made in China

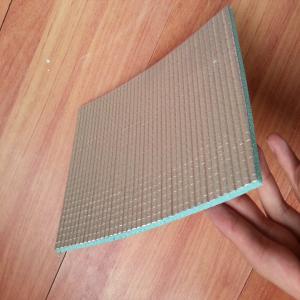

Masking tape is using crepe paper as backing material and coated with natural rubber adhesive

Standard size: 24mm*30, 48mm*30m,0.99m*1800m,1.22m*1800, etc.

Application : widely used for painting masking, furniture, shoe material production, auotmobile painting.

| Item No. | Thickness (micron) | Initial Tack | Holding Power (hour) | Tensile Strength (N/cm) |

| Adhero1-1 | 160 | 10# | 2 | 16 |

| Adhero1-2 | 150 | 8# | 3 | 16 |

| Adhero1-3 | 150 | 10# | 3 | 16 |

| Adhero1-4 | 160 | 8# | 4 | 26 |

| Adhero1-5 | 150 | 10# | 15 | 30 |

| Adhero1-6 | 140 | 10# | 10 | 26 |

Pakaging & Shiping 2015 Hot Sale Waterproof Masking Tape Made in China

Packaging Detail | standard packing / genuine packing / as per customer's packing instruction |

Delivery Detail | 15 ~ 30 days after receiving the deposit |

Our service of 2015 Hot Sale Waterproof Masking Tape Made in China

1. We have good and professional team

2. We accept any drawings or your samples to develop new product

3. Any small problems will be solved at the most prompt time

4. We always offer relative technical support, quick response, all your inquire will replied within 24 hours

Company Information

CNBM International Corp., established in 2004, is the business entity fortrade and logistics of CNBM Group, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council of People’s Republic of China.

Adhero Technology is the adhesive tape division of CNBM International Corporation. Over the past decade we have been developed into a leading manufacturer of adhesive tapes in China. We mainly supply various kinds of adhesive tapes as BOPP packing tape, cloth duct tape, double sided taoes, PVC tapes, Aluminum foil tape etc.

FAQ: What are your company advantages?

Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

5. CNBM have export to more than 100 countries with 20 year's experience

- Q: What are the vibration damping benefits of using automotive plastic products?

- The vibration damping benefits of using automotive plastic products include reduced noise and improved comfort for passengers, increased vehicle stability and durability, and enhanced overall driving experience. Plastic materials have inherent damping properties that absorb and dissipate vibrations, minimizing the transmission of noise and vibrations from the engine, road, and other sources. This helps create a quieter and more comfortable cabin environment. Additionally, the use of plastic components can help reduce the overall weight of the vehicle, leading to improved fuel efficiency and better handling. Plastic products also offer excellent resistance to corrosion, which contributes to the longevity and durability of the vehicle. Overall, automotive plastic products provide effective vibration damping, leading to a smoother and more enjoyable driving experience.

- Q: Are automotive plastic products resistant to UV radiation?

- Yes, automotive plastic products are often designed to be resistant to UV radiation.

- Q: What kinds of plastics are there in automobile interiors?

- Heat resistant ABS: high heat resistance, tough and tough balance, excellent spraying and electroplating ability. It is applied to the air outlet of automobile air conditioner.PET enhancement grade: excellent mechanical properties, good dimensional stability, high heat resistance, good surface gloss and good color stability. It is applied to the air outlet of automobile air conditioner. Import car market

- Q: How do you handle plastic scratches on cars?

- Use a damp cloth dipped in detergent wipe, to use a bit of force, it is easy to wipe the black plastic, the last time I drew a silver car black car on the black plastic, so clean, and detergent on the car paint without damage. You can have a try。

- Q: How do automotive plastic products contribute to improved vehicle braking systems?

- Automotive plastic products play a crucial role in enhancing vehicle braking systems by offering key components such as brake pads, calipers, and brake lines. These plastic products provide several advantages like reduced weight, improved heat dissipation, and enhanced durability, resulting in better braking performance and increased safety on the roads.

- Q: Are automotive plastic products resistant to electromagnetic interference?

- Yes, automotive plastic products can be designed to have resistance to electromagnetic interference (EMI). Various techniques such as shielding additives, conductive coatings, and metalized layers can be incorporated into automotive plastic components to minimize the impact of EMI on electronic systems and ensure their proper functioning.

- Q: What are the considerations for using plastic in automotive airbag and restraint systems?

- There are several considerations when using plastic in automotive airbag and restraint systems. First, the plastic material needs to be strong and durable to ensure the system can effectively protect passengers in the event of a collision. Additionally, the plastic must be resistant to extreme temperatures, as airbags are exposed to high heat during deployment. It is also crucial to choose a plastic that is lightweight, as it helps reduce the overall weight of the vehicle and improve fuel efficiency. Finally, the plastic used should meet safety standards and undergo rigorous testing to ensure its reliability and performance in real-life scenarios.

- Q: What is the plastic part of the BYD chassis?

- Hello, basically the plastic clips are fixed. Very few parts are self - Powered wire screws. Happy car!

- Q: Auto chassis, plastic parts for spraying?

- There are many 4S shops to spray armor promotions or as being one of the preferential policies, but in fact many 4S shop no spraying operation method, operation procedures and standards clear spraying dosage, protective measures are not clearly defined, but as consumers spend more money to buy a comfort is innocent.

- Q: How do automotive plastic products contribute to occupant protection in case of accidents?

- Automotive plastic products play a significant role in occupant protection during accidents by offering various safety features. These products, such as airbags, seatbelts, and dashboard materials, are designed to absorb and distribute impact forces, reduce the risk of injury, and enhance overall vehicle safety. Additionally, the lightweight nature of plastic components improves fuel efficiency, which indirectly contributes to occupant protection by reducing the severity of collisions.

Send your message to us

2015 Hot Sale Waterproof Masking Tape Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches