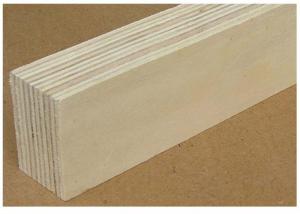

Supply 4.5-9.0mm Good Quality Wood Fiber Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

Wood fiber (xylem fiber) is a natural renewable wood after chemical treatment and mechanical processing organic flocculent fiber material.

It is widely used in field of mortar and concrete gypsum composite recruiting materials, wood fiber pulp sponge, asphalt road etc., to prevent cracking of the coating, increase water retention and improve the stability of production and construction of conformance, increase strength, has a good effect on surface adhesion. Its main function is: thixotropic, protective, absorption, carrier and filler

2.Product Characteristic

1.The cellulose is insoluble in water, acid and alkaline solution; neutral pH value, can improve the corrosion resistance of the system.

2.lignocellulose the proportion of small, large specific surface area and has excellent heat preservation, heat insulation, sound insulation, insulation and air permeability, thermal expansion uniform can not afford to shell cracking; higher wet film strength and cover effect.

3.lignocellulose has excellent flexibility and diversification, the mixed form three-dimensional network structure, enhances the system support and durability, and can improve the system stability, strength, density and evenness.

4.wood fiber structure of cohesive, the uniformity of the processing of precast slurry (dry and wet materials) remained intact stability and reduce the contraction and expansion, the construction or prefabricated parts precision is improved greatly.

5.wood fiber has strong anti freeze and heat resistant ability, when the temperature reaches 150 DEG C insulation for a few days, when up to 200 DEG C insulation dozens of hours; when more than 220 DEG C to heat for several hours.

3.Parameter

Encoding products:dndwhz4.5NE2-800Dndwhz4.5NE2-800

Product specifications: 4.5*1220*2440mm

Production line: Germany full set of imported 4 feet continuous flat production line (Simbel Campo)

Mills: Siempelkamp

Material: all poplar wood, all pine, pine, miscellaneous, Yang miscellaneous.

Color: light color wood color

Environmental protection grade / glue: E2

Density: 800 kg/m, 830kg/ m fand fand

4.Reference Picture

- Q:What are the characteristics of bamboo products?

- 4, wood composite floor: Bamboo and wood composite flooring is a composite of bamboo and wood products. Its panel and floor, using a good bamboo, and its core layer for the fir, camphor and other wood. Its production production to rely on sophisticated machinery and equipment and advanced science and technology and standardized production process, through a series of anti-corrosion, anti-corrosion, moisture, high pressure, high temperature and gluing, rotary grinding and other nearly 40 complicated process, to become A new type of composite floor. This floor has the advantages of bamboo flooring: the appearance of natural fresh, delicate and smooth texture, moisture and moisture, as well as toughness and toughness, flexibility, etc .; at the same time, the hard surface can be hard with wooden flooring in the common species such as cherry, And so on. On the other hand, because the floor core material used wood as raw material, so its excellent stability, strong and durable, good foot feeling, style coordination, sound insulation performance, and Dongnuanxialiang, especially for home environment and sports entertainment Places such as interior decoration. From a health point of view, bamboo flooring is particularly suitable for the elderly population in the city as well as infants and young children, but also for the movement of the crowd also has a protective role.

- Q:garden wood oil - garden wood oil from the preparation of natural raw materials

- effectively prevent the cracking of wood, significantly delay the aging of wood deformation, and does not change the true nature of wood

- Q:How to completely remove the stickers on wood products

- 6. Bad toothpaste, a dollar, poor quality toothpaste used in the filler material coarse, just as a grinding agent, emergency use; 7. carburetor cleaning agent, 7 yuan a bottle, but will hurt the paint, with caution; 8. Water sandpaper grinding, generally do not test their own, this method is applicable to experienced old pull gold technician.

- Q:Water content is too high or too low, will cause the quality of wood in the home improvement

- The wood-based panel is the decomposition of wood into wood or wood pulp, and then from the new manufacturing plate

- Q:Outdoor wood products, with wood wax good oil is good?

- if you do not consider the cost, of course, is better than wood wax oil, but wood can meet The basic requirements of the outdoor (anti-corrosion, moisture, anti-cracking) later or the need for regular maintenance. -

- Q:Wood products need to use wood flame retardant?

- The impregnation treatment of the wood material flame retardant treatment method

- Q:How to fill out the export of wood products and wood furniture business self - control situation

- First, the purpose In order to meet the needs of customers, product quality in line with the importing country mandatory regulatory standards, to avoid product quality and safety problems, the company's export products required for raw and auxiliary materials, semi-finished products, finished special self-control self-control plan.

- Q:Now in the home decoration, the individual use of white latex for wood products joints of the binder

- You are in the decoration with the wood to buy home, the best place in the decoration site for a few days and then use the tube door is also a security door, is a series of steel fire door

- Q:Who knows the art of wood on the brush is what oil?

- First, simply answer as follows: The first layer is tung oil, not paint, the role of tung oil should be anti-corrosion, the outside layer is a varnish, varnish role is smooth and bright.

- Q:Wood products hand string which is better

- If it is on the collection of valuable wood bracelet material, incense is undoubtedly the best (but the real natural rare rare rare, artificial medicine Shen majority), and then the pear material (to Hainan pear for the most), as well as lobular red sandalwood (Often wear on the human body has conditioning the role of blood) and some valuable wood

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Supply 4.5-9.0mm Good Quality Wood Fiber Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products