High Quality Pine LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

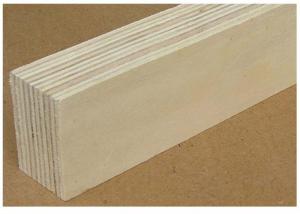

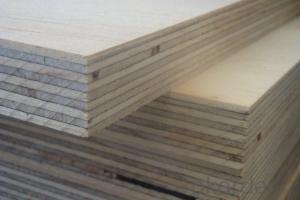

Specifications of the High Quality Pine LVL

| Size | Wide(Max.1250mm)*length(Max.6000mm) |

| Thickness | Max.50mm |

| Glue | WBP/melamine/MR |

| Material | pine wood |

| Usage | For construction headers, wood beams,rimboard,and edge forming material |

| Grade | A Grade |

| Package | standard export packing, pallet with metal strip |

Introduction of the High Quality Pine LVL

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layersof thin wood

assembled with adhesives. It offers several advantages over typical milled lumber.it is stronger, straighter,

and more uniform. It is much less likely than conventional lumber to warp twist, bow, or shrink due to its

composite nature. Made in a factory under controlled specifications,LVL products allow users to reduce

the onsite labor.

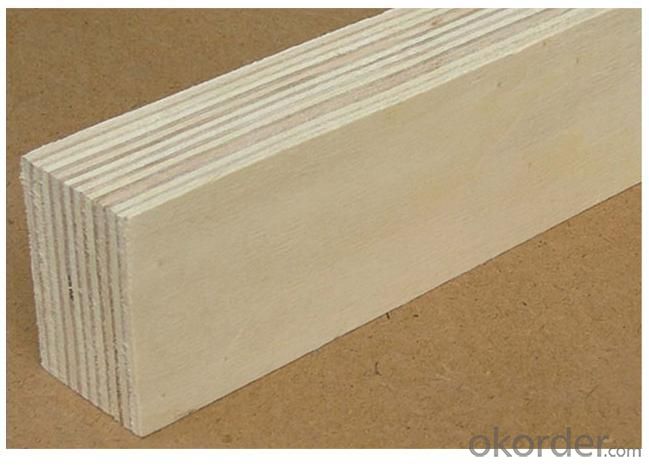

The usage of the High Quality Pine LVL

They are typically used for headers, beams, rimboard, and edge forming material.It is similar in

appearance to plywood without crossbands and is typically rated by the manufacturer for elasticmodulus

and allowable bending stress. Common elastic moduli are 1.8, 1.9, and 2.0 million psi, and common

allowable bending stress values are 2800 and 3000 psi.

Features of the High Quality Pine LVL

1.) High bending strength

2.) little liner expansion con efficient

3.) strong nail holding

4.) moisture proof and easy work

5.) tight construction and high stregth

6.) no ratten or decay

7.) low formaldehyde emission

The following pictures for your reference.

- Q: Building decoration commonly used in wood decorative products which

- Glulam board board, Olsen Sakamoto boardboard, Ou Song board glued together Wood is one of the earliest materials used in architecture and decoration. Woody light, high strength, strong elasticity and toughness, easy processing and surface finishing, especially wood with natural texture, warm visual and tactile feel, which is unmatched by other materials, so they are still in the building Decoration is still occupying a very important position. Here to learn about the basic classification of wood knowledge, as well as home improvement in the common wood products.

- Q: What kind of wood is the fir tree?

- The finished products are often known for their bold and bold style and require the artist to have a very high artistic accomplishment. Jin Si Nan ebony, due to natural variation, buried in the river bed and other low-lying sludge, after thousands of years of materialized; its not fade, not rotten, not insects, hard material, is the production of works of art, antique furniture ideal Of the material, in the art of ebony as a heirloom, evil spirits. Ebony handicrafts to Zen Shen Yuan works for the first push, the carving, the integration of round carving, carving, carving, carving, relief, carving and other carving techniques of the essence, everywhere meticulous, knife was meritorious, master craftsman , Will be silent flowing traditional culture into them, into a piece of magnificent works of art, from the shape, structure to each fit, each decoration, are abide by the ancient law, reached the United States and the United States Huan of the height, the concept of such as seamless, strokes like jade seamless. Its pure hand carving is not only the master of Zen Shen Yuan show, but also the creators will character, character and even ideas into the crafts, given its life process, but also its rise to the art of the best of the soul; Zen Shen Yuan handicrafts, fine Elegant selection of ebony, ancient art, fine carving, floating fragrance, both Kuang Shuo the culmination of this skill, but also the aesthetic elements of the cohesion of God.

- Q: The key to adding the environmental protection flame retardant treatment method

- The advantage of spray treatment is to effectively control the spread of fire, the amount of less, the physical and mechanical properties of wood less affected, the flame resistance of the anti-flow is good

- Q: Wood products such as wardrobes want to use color on what?

- you Product description will be introduced at the time of purchase. When you pay attention to whether the paint is green on the line, are marked on the product.

- Q: How should the wood product be cleaned?

- Maintenance of wooden furniture 1. often with a soft cloth along the wood texture, for the furniture to dust, before the dust, should be in the soft cloth dip on the spray agent (Bi Lizhu), do not wipe with a dry cloth, so as not to rub the flowers. 2. Solid wood furniture in a more dry environment, the use of artificial humidification measures, such as: regular use of soft cloth wring dry wipe the furniture. 3. Regular waxing, every 6 to 12 months, with a paste wax for the furniture on a layer of wax, wax before, should first use the more mild non-alkaline soapy water to wipe the old wax.

- Q: The law required for timber import and export, and the relevant international agreements

- Second, the relevant international agreement In May 2003, the European Union introduced the FLEGT Action Plan proposal; in July 2004, the European Commission proposed the EU import timber resource approval system proposal, it is proposed to negotiate with the partner countries on the signing of the partnership agreement, and report the assessment of the FLEGT action plan on the timber Export countries and the EU may have the impact. 2. International and EU trade in timber At present, the international timber key markets include the EU, Central Africa, South America, Southeast Asia, the United States, Japan, China and Russia. Russia and African countries mainly export logs and plates; Asia and South America mainly export high value-added wood products, such as furniture, paper and wood. According to OECD, the world's annual timber trade volume of up to 150 billion euros. The EU imports hardwood, logs, veneer and slabs from North America; logs are imported from Russia; timber imports from Africa, Asia and Latin America are modest. The proportion of timber trade within the EU is as high as 80%. But the EU is not only an important market for legally logging timber trade, but also a third country's illegal logging market. 3. Illegal logging of timber trade is rampant The World Bank report shows that a significant portion of the global timber trade is for the illegal logging of timber trade. Illegal logging mainly occurs in developing countries and "threshold countries". There are indications that large quantities of timber illegally harvested by developing countries such as Indonesia, Myanmar and Cambodia are mostly exported to other countries and processed locally and sold at low prices to Europe. European legally harvested wood processing products are therefore not price competitive. As furniture, paper and wood products such as the longer delivery time, more varieties, and a wide range of timber, it is difficult to check the legitimate sources of raw materials used.

- Q: Wood or wood products should be used to disinfect

- 3. Regular waxing, every 6 to 12 months, with a paste wax for the furniture on a layer of wax, wax before, should first use the more mild non-alkaline soapy water to wipe the old wax. 4. As far as possible with a mat pad under the hot plate, so as not to spill food soup, stain or damage the desktop. 5. Try to avoid contact with corrosive liquids, alcohol, nail polish, lacquer remover. Maintenance of wooden furniture

- Q: garden wood oil - garden wood oil from the preparation of natural raw materials

- effectively prevent the cracking of wood, significantly delay the aging of wood deformation, and does not change the true nature of wood

- Q: What woodworking woodworking lathes can be processed?

- Ordinary carpentry lathes can be processed, CNC woodworking lathes can do. Ordinary carpentry can not be processed, CNC woodworking lathe can not do.

- Q: Wood products waxing

- 3, do not wax in the sun. A little bit of the closure does not matter, moderate ventilation on the fight process is good. Hope to help you

Send your message to us

High Quality Pine LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords