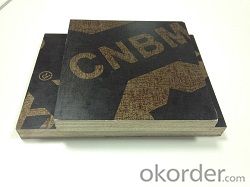

Film Faced Plywood Brown / China & Dubai / Brand: CNBM / COMBI Core / Phenolic / 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

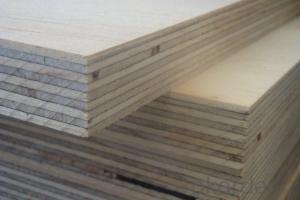

Film Faced Plywood is a kind of plywood which inside plywood assembled of veneers and cross band glue impregnated veneers, and outside face veneer on either side topped with glue impregnated film. The glue is used differently like WBP, Phenolic Resin, etc. The veneer made of timber & wood such as Hard Wood, COMBI, Poplar, Birch, etc. Pack in encase in plates and laminated under very high pressure and heat. For the quality two times hot pressure is better than one time hot pressure.

Packaging & Delivery

(1).Packaging Detail: pallets package as standard shipment request.

(2).Delivery Detail: There are two options for customer.

(A).Stock from Jebel Ali Free Zone warehouse in Dubai, delivery available in one day after payment received.

(B).Booking from factories, delivery in 40 days after PI confirmed.

Specifications of Film Faced Plywood (Brand name: CNBM)

(1)Size: 1220 mm×2440 mm, 610 mm×2440mm, other special sizes.

(2)Thickness: 18mm

(3)Core: COMBI, Hard Wood.

(4)Glue: Phenolic

(5)Film: Brown

(6)Pressure: Two time hot press.

(7)Moisture: 6%-9%.

(8)Thickness tolerance: +/-0.2mm.

(9)Duration time: can be 8/9 times used

(10)Usage: For projects requested high quality and specific strength.

(11)Payment term: T/T or L/C at sight.

(12)Manufacture in China and Stock in Dubai,UAE

Advantage of Film Faced Plywood:

(1).Can be used not only one time, profitable as a property.

(2).High strength as wood product.

(3).Stability.

(4).Resilience.

(5).Superior Resistance.

(6).Smooth film faced as mirror.

(7).Flexible. Can be cut from one sheet to smaller specific size pieces.

- Q: Building decoration commonly used in wood decorative products which

- 1, wood classification Wood according to different classification criteria can be divided into different types, there are two general classification methods, one by tree species; the second is by the degree of processing points. According to tree species: divided into coniferous trees and broadleaf trees Wood Category 1: by tree species points conifer Leaves slender as needle, mostly long green trees pine, pine, shirt wood, ginkgo and so on. Trunk material is straight and tall, easy to get great material; material uniform and soft, easy processing, is a soft wood; material strength, surface density and expansion and contraction of small, strong corrosion resistance. It is suitable for the load-bearing structure of the hidden part of home improvement. Broadleaf trees Leaves large, veins reticulate, deciduous. Ash, camphor, walnut, cherry, teak, red sandalwood, poplar, boxwood, red beech, white beech and so on. Trunk straight part of the shorter, hard material, processing more difficult, is a hard wood; hardwood swelling and warping deformation, easy to crack; texture natural beauty. It is suitable for making the main finishes of home improvement decoration and furniture manufacturing. According to the degree of processing points: divided into the original article, logs and board three kinds of materials Wood classification 2: according to the degree of processing points The original: the trees are cut, the pruning, remove the skin, roots, trees, but no processing of wood

- Q: How does the wood bleach?

- Hydrogen peroxide, also known as hydrogen peroxide, which is the application of more bleaching effect of a better bleach. Commonly used concentration of 15-30%, it will be applied to the surface of the wood can release a strong force of oxygen, decomposition of wood pigment, so that white, in order to accelerate the release of oxygen, hydrogen peroxide can be mixed with ammonia, with this Bleaching agent wet the surface of the wood, after ten minutes, with cold water to bleach off on it. Ammonia can not be added too much, under normal circumstances, 25% of the amount of ammonia added about 5-10% of hydrogen peroxide.

- Q: How does pure handmade wood products sell?

- note: 1, choose what kind of sales program to combine their own actual situation and planning for future development. 2, the proposed combination of centralized sales program, there will be a good effect.

- Q: How can the carved wood products make the surface smooth and anti-corrosion?

- 4. Before use, stir evenly, no need to dilute; if the product viscosity is high, but also into a small amount of special thinner, adding the amount should not exceed 10%. 5. Brush need to use soft brown hair brush, along the direction of wood texture evenly, thin brush again, after brushing to remove excess wood wax, brushing the amount must be less, can not be painted too thick; to be hard after the surface, Paint gently polished, wipe, 12 hours can be painted the second time.

- Q: How to avoid wood deformation

- Whether it is solid wood or man-made sheet, all the wood products contain a certain amount of water. Many consumers think that the more dry the better wood, in fact, this view is biased. Wood moisture content only in the normal range to maintain stability, in order to ensure that the decoration does not appear quality problems. General household use of wood materials, moisture content should be about 8% is appropriate. Water content is too high or too low, will cause the quality of wood in the home improvement.

- Q: American wood products formaldehyde emission standards

- At present, US environmentalists are strongly urging the US Environmental Protection Agency (EPA) to set limits on the formaldehyde content of household wood products to protect the public from the hazards of formaldehyde gases released from wood products. This long-term exposure to toxic gases Carcinogenic have a potential link. Established in 1892, the Sierra Earth Club and other 20 organizations have submitted their applications to the EPA. We hope that the EPA will adopt the recently defined formaldehyde content standard at the California Air Resources Conference and hope to promote its application throughout the country. California has enacted regulations that severely limit the release of formaldehyde from wood products and final products sold and used in California, which will reduce 57% (700t) of formaldehyde per year by 2011 freed.

- Q: garden wood oil - garden wood oil from the preparation of natural raw materials

- In the absorption of a normal performance of the board on a layer of oil, the amount per square meter is about 40 to 70 ml. The following are the same as the "

- Q: Can you bring wood products from New Zealand?

- Can be kind, no creatures in China do not let them General wood material is not found after the inspection will allow transit

- Q: Wood preservatives

- This Nima Dolma in the food inside, the traditional wood preservatives are generally arsenic boron copper chromium and other compounds, such as CCA, CCB; quaternary ammonium salts, such as ACQ; file category, CA.

- Q: Wood products in what kind of temperature and humidity placed the most appropriate?

- Temperature: +5 to + 35 ° C ? 2. Humidity: no more than 85% RH ? 3. Atmospheric pressure: 80KPa when 106KPA Avoid direct sunlight or other direct heat radiation. ? 5. Flammable, corrosive gas environment. ? 6. Strong turbulence and convection around a strong electromagnetic field, strong vibration effects.

Send your message to us

Film Faced Plywood Brown / China & Dubai / Brand: CNBM / COMBI Core / Phenolic / 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords