Construction Pine LVL Beam/LVL Board Scaffolding OSHA Waterproof (Laminated Veneer Lumber)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

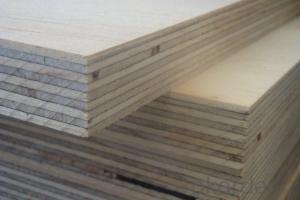

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives. It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber : Made in a factory under controlled specifications, it is stronger, straighter, and more uniform, which is considered as a perfect alternative rather than solid wood and it uses wood at its utmost, which helps to reduce wood wast and protect the enviroment.

Name:LVL Beam/LVL Board

Moisture: 12-17%

Core: Pine

Usage: Furniture, Construction, Packing

Packing: inter packing:0.20mm plastic bag with wooden pallets then steel strip for strength

Delivery time: 15~25 days on receipt of deposit or original L/C

Mini order: 1X40'GP

Size availeble:

for LVL beam:

40x40mm; 40x60mm; 60x60mm; can be customized upon request.

for LVL board:

225x38x3900mm; 225x38x5900mm

LVL Beam Picture

Detailed picture LVL beam

LVL Beam Site apply: Demo as slab or wall formwork assemblied

OSHA standard: LVL board

Packing: LVL board

Storage: LVL board

- Q: Why moldy wood products after cleaning will be moldy

- This approach applies to confined small space, such as wardrobe, shoe and so on. As at the bottom of the closet, the inside of the cabinet can be covered with newspapers, it can not only absorb moisture, and the smell of ink on the newspaper can also insect repellent. But also in the wet shoes filled with newspapers, in the absorption of water at the same time can keep the shoes are not deformed. Mold is mainly because of wet it, sofas, carpets, quilts, pillows and even plush toys are likely to be tidal infestation, for fabric sofa and carpet, be sure to regularly remove the surface of the dust, if necessary, gently blow with a hair dryer. When the weather is clear, it is necessary to seize the opportunity to put the sun in the sun under the sun. Wooden furniture moisture can be used with some good absorbent paper or plastic paper attached to the surface of wood furniture. For leather sofas, you can put some desiccant properly to keep dry.

- Q: Is it possible to pay for the processing of timber?

- Yes, yes, processing wood is to pay VAT. Second, note: 1. The acquisition of timber (belonging to agricultural products) to the farmers shall be issued by the acquirer to the farmers (the tax bureau only) to the farmers. The acquirer shall calculate the deductible input tax according to the acquisition certificate at 13%.

- Q: Guizhou furniture for what kind of wood furniture

- Wood furniture, the balance of moisture must be less than 15%, only suitable for use in Guizhou climate conditions. Otherwise, the wood products will crack or deform. Wood is a hygroscopic material, wet material placed in the air, will continue to evaporate moisture; dry material placed in the air, the air will be absorbed by the wood moisture.

- Q: Is it good to use wood products?

- Of course, is a good steel, modern and stylish The key is to use wood is not environmentally friendly ah Taobao can go to see, there are many options. I am a friend is to buy on Taobao, very good to see Jesus I am ready to buy

- Q: How can the carved wood products make the surface smooth and anti-corrosion?

- 4. Before use, stir evenly, no need to dilute; if the product viscosity is high, but also into a small amount of special thinner, adding the amount should not exceed 10%. 5. Brush need to use soft brown hair brush, along the direction of wood texture evenly, thin brush again, after brushing to remove excess wood wax, brushing the amount must be less, can not be painted too thick; to be hard after the surface, Paint gently polished, wipe, 12 hours can be painted the second time.

- Q: Laser marking machine engraved wood products will be black

- I do not know what type of situation you are using. In this case, by reducing the current, will improve the black situation, and then yellow.

- Q: Wood products by polishing and then Varnish, dry after not smooth it?

- The first request in the paint before the 380 # sandpaper with full polished, polished wooden handle surface is smooth without rough feeling,

- Q: How to make wood live, wood products can be electrostatic spraying?

- The saying is to let the wood wet a little. Wood this is the insulator, but the high water content later, you can become a conductor.

- Q: What are the wood products? Is the wooden product environmentally friendly?

- Whether the wood products are environmentally friendly depends on the production process, whether it contains toxic and hazardous substances, whether the transition process waste a lot of resources. Products that do not have an impact on the environment do not exist. Production of any product will consume energy, and materials and so on. Only relatively environmentally friendly products exist, that is, the application of time or the number of applications and the ratio of the greater the better. But also take into account the product after the retirement of the environment to bring the burden of the smaller the better.

- Q: The Wooden goods maintenance methods

- away from heat, in the cold winter, especially in the north of the people, there will be heating experience.

Send your message to us

Construction Pine LVL Beam/LVL Board Scaffolding OSHA Waterproof (Laminated Veneer Lumber)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords