Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Guidelines

Structure of product description:

What is the product?

High Quality Structural Carbon Steel H Beam

OKorder is proud to be offering hot rolled High Quality Structural Carbon Steel H Beams. Our Steel Beams meet all GB, JIS, and ASTM ST standards; available in Q235, Q345, SS400, S235JR, S275JR, S355JR grades. We are able to meet all client requirements as well as offer standard sizes of 5.8-12m - all either painted, galvanized or punch holed.

What is the intended use of the product?

The intended use of High Quality Structural Carbon Steel H Beam

Our H Beams are ideal for:

Construction support beams for commercial and residential construction

Mezzanines and platforms

Bridges

Trailer and truck bed framing

Machine bases

What is the product’s advantage?

The advantage of High Quality Structural Carbon Steel H Beam

OKorder is able to quickly ship orders within 20 days of receiving a deposit or original L/C. All products are shipped with ISO, SGS, BV, and CIQ certification as well as additional standards.

Main features of the product

Main features of High Quality Structural Carbon Steel H Beams

- ISO, SGS, BV and CIQ Certified

- Custom Sizes Available

- Shipped within 20 Days

FAQ:

- 3 FAQ’s minimum per product (use of single and phrase keywords in the question and answer of the FAQ’s)

Q1: Why you buy Materials & Equipment from OKorder.com ?

A: All products on OKorder.com are carefully selected from China's quality manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and commitment toward supply chain safety and customer satisfaction.

Q2: What is Carbon Steel ?

A: Modern steels are made with varying combinations of alloy metals to fulfill many purposes. Carbon steel, composed simply of iron and carbon, accounts for 90% of steel production.

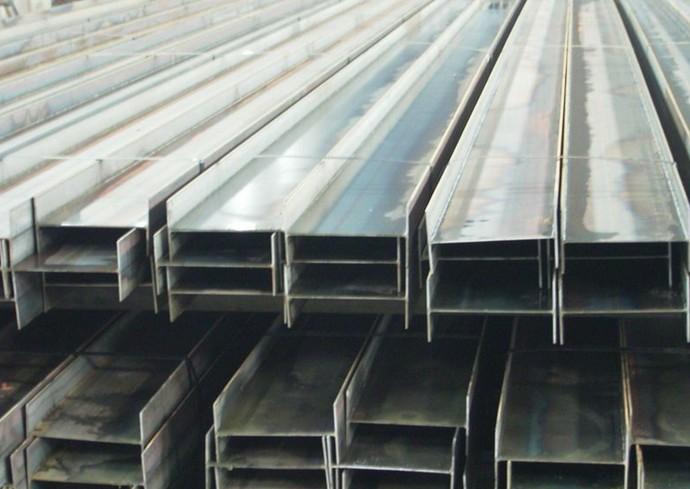

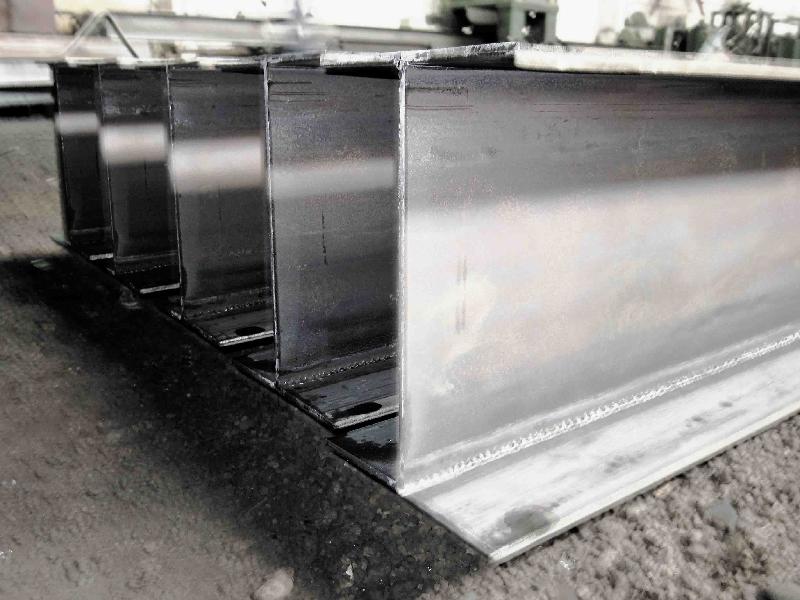

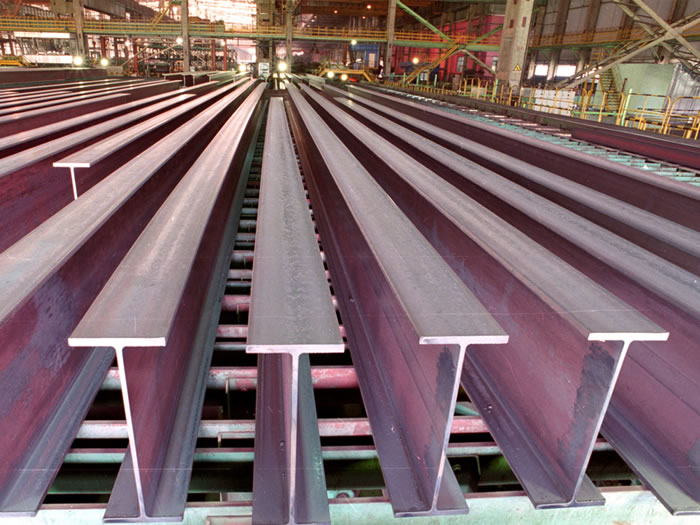

Images:

Specifications:

Specifications of High Quality Structural Carbon Steel H Beam

Place of Origin: | China (Mainland) | Grade: | SS400 | Technique: | Hot Rolled |

Application: | building,construction | Length: | 6-12m | Standard: | JIS |

Flange Width: | 50-300mm | Flange Thickness: | 5-16mm | Web Width: | 100-900MM |

Web Thickness: | 7-28MM | Brand Name: | NBSTEEL | Model Number: | 100*50*5*7-900*30*16*28 |

Standard: GB, JIS, ASTM ST

Material: Q235, Q345, SS400, S235JR, S275JR, S355JR

Length: 5.8-12m or according to our clients' requirements

Origin: Tangshan, China

Package: load on 20 feet/40 feet container or by bulk according to the quantity and our client's requirement

Delivery time: within 20 days after receiving deposit or original L/C

Certificate: ISO, SGS, BV, CIQ or other test

Technic: Hot rolled

Surface: painted, galvanized or punch holes

Main market: East-south Asia, Mid-east, South American

Usage: Construction structure and Frame use

Other Main products: Angle steel, I beam and Channel steel

Images:

- Q: Can steel I-beams be used for retaining walls or foundation support?

- No, steel I-beams are not typically used for retaining walls or foundation support. These types of structures require specific materials, such as reinforced concrete, that can provide the necessary strength, stability, and durability to withstand the forces exerted by the soil and other external factors.

- Q: Are steel I-beams suitable for mezzanine floor constructions?

- Yes, steel I-beams are commonly used in mezzanine floor constructions due to their strength, durability, and ability to support heavy loads. They provide stability and structural integrity, making them a suitable choice for mezzanine floor constructions.

- Q: Can steel I-beams be used to create open floor plans in buildings?

- Yes, steel I-beams can be used to create open floor plans in buildings. Steel I-beams are known for their strength and ability to span large distances, making them ideal for creating wide open spaces without the need for additional support columns or walls. They can be used to support the weight of multiple floors above, allowing for the creation of open and spacious layouts. Additionally, steel I-beams are often used in commercial and industrial buildings where large open spaces are desired, offering flexibility in terms of design and functionality.

- Q: How do you anchor steel I-beams to the foundation?

- When it comes to anchoring steel I-beams to a foundation, construction commonly employs several methods. One technique frequently used is the utilization of anchor bolts or anchor rods. These bolts or rods are typically embedded into the foundation during its construction. Subsequently, the I-beams are positioned on the foundation, and the flange plates of the beams are drilled to align with the anchor bolt locations. Following this, the beams are fastened to the foundation using nuts and washers, guaranteeing a secure connection. Another approach involves the application of epoxy anchors. To install epoxy anchors, holes are drilled into the foundation, and epoxy resin is injected into these holes. Once the epoxy has solidified, steel rods or threaded rods are inserted into the epoxy-filled holes. The I-beams are then attached to these rods using nuts and washers, creating a sturdy and dependable anchor. In certain instances, welding may be employed to anchor steel I-beams to the foundation. This method entails welding steel plates to the foundation and subsequently welding the I-beams to these plates. Welding offers a permanent and durable connection, but it necessitates skilled welders and proper welding techniques to ensure structural integrity. The choice of a specific method for anchoring steel I-beams to a foundation depends on various factors, including load requirements, foundation type, and construction regulations applicable in the area. It is crucial to consult structural engineers and adhere to local building codes to ensure the correct and safe installation of steel I-beams on a foundation.

- Q: What type of I-beam should be used for span 8m? Beam load is mainly 10cm thick concrete floor

- I-beam is also called steel girder (English name Universal Beam). It is a strip of steel with an I-shaped section. I-beam is made of ordinary I-beam and light i-beam. It is a section steel with an I-shaped section.

- Q: How do steel I-beams compare to reinforced concrete beams in terms of cost and performance?

- When it comes to cost and performance, steel I-beams and reinforced concrete beams each have their own advantages and disadvantages. In terms of cost, steel I-beams generally have a higher upfront expense compared to reinforced concrete beams. This is due to the higher cost of steel fabrication and installation, which includes factors like labor, transportation, and specialized equipment. On the other hand, reinforced concrete beams are typically more cost-effective initially because the materials used are relatively inexpensive and easily accessible. However, it is important to consider that the long-term maintenance and repair costs for reinforced concrete beams can be higher. Concrete may require regular inspections and potential repairs due to cracks or deterioration. In terms of performance, both steel I-beams and reinforced concrete beams have their own strengths. Steel I-beams are known for their high tensile strength, allowing them to withstand heavy loads and provide excellent structural support. They also offer more flexibility and can be easily modified or adjusted if necessary. On the other hand, reinforced concrete beams are known for their durability, fire resistance, and ability to withstand extreme weather conditions. They have good compressive strength and can handle high loads as well, but their tensile strength is relatively lower. Ultimately, the choice between steel I-beams and reinforced concrete beams depends on various factors, such as the specific project requirements, design considerations, budget constraints, and local building codes. It is crucial to consult with structural engineers and professionals to determine the most cost-effective and performance-oriented solution for a particular construction project.

- Q: What are the different aesthetic options available for steel I-beams?

- There are several aesthetic options available for steel I-beams to enhance their visual appeal and integrate them seamlessly into architectural designs. Some of the popular aesthetic options include: 1. Powder Coating: Steel I-beams can be powder coated with a wide range of colors and finishes, allowing them to match or complement the surrounding environment or architectural elements. This process not only adds a layer of protection against corrosion but also provides a durable and attractive finish. 2. Galvanization: Galvanizing steel I-beams involves applying a layer of zinc coating to protect against rust and corrosion. This option gives the beams a distinctive silver-gray appearance, which can add an industrial or contemporary aesthetic to the overall design. 3. Polishing: Polishing steel I-beams creates a smooth and reflective surface, giving them a sleek and modern look. This option is often used in contemporary architectural designs where a high-end, luxurious feel is desired. 4. Brushed Finish: A brushed finish involves creating a pattern of fine lines on the surface of the steel I-beam. This option can provide a unique texture and a more tactile experience, making it a popular choice for designs that aim to incorporate an element of artistic expression. 5. Custom Paint or Coating: Steel I-beams can also be customized with specific paint colors or coatings to match the desired aesthetic. This option allows for creativity and personalization, making it an excellent choice for projects that require a specific color scheme or branding. It's important to note that the choice of aesthetic options for steel I-beams may vary depending on the manufacturer, project requirements, and budget constraints. Consulting with professionals such as architects, engineers, or steel fabricators can provide valuable insights and recommendations on the best aesthetic options available for steel I-beams in a particular project.

- Q: Can Steel I-Beams be used for agricultural buildings?

- Yes, steel I-beams can definitely be used for agricultural buildings. Steel I-beams are known for their strength and durability, making them ideal for supporting large agricultural structures. They are commonly used in the construction of barns, stables, storage facilities, and other agricultural buildings. Steel I-beams have high load-bearing capacities, which means they can handle heavy equipment, machinery, and storage requirements often associated with agricultural operations. Additionally, steel is resistant to pests, fire, and rot, making it a reliable choice for agricultural buildings that need to withstand harsh conditions. Furthermore, steel I-beams can be easily customized and assembled, allowing for flexible designs that can accommodate various agricultural needs.

- Q: Are steel I-beams fire-resistant?

- Steel I-beams are not inherently fire-resistant. However, they have a high melting point which allows them to withstand fire for a longer duration compared to other building materials like wood. To enhance their fire resistance, steel I-beams are often coated with fire-resistant materials or encased in fire-rated materials such as concrete or gypsum to provide additional protection against fire.

- Q: Are there any maintenance requirements for steel I-beams?

- Yes, steel I-beams typically require regular maintenance to ensure their structural integrity and longevity. This includes periodic inspections to check for signs of corrosion, cracks, or other damage. Cleaning and applying protective coatings may also be necessary to prevent rust and deterioration. Additionally, proper lubrication of moving parts, such as bolts and connections, is important to prevent friction and wear. Overall, regular maintenance is essential to keep steel I-beams in optimal condition and ensure their safe and reliable performance.

Send your message to us

Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords