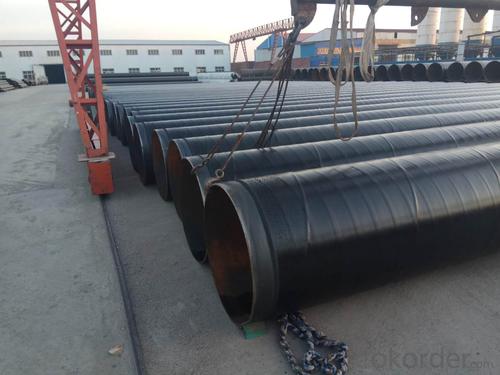

Composite Strengthening Grade 3PE Anticorrosion Gas Pipeline 3PE Anticorrosion Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 655 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3PP anticorrosion: pipeline three layer PP corrosion protection structure: the first layer of epoxy powder (FBE50 to 100um), two layers of adhesive (AD) 250 ~ 400um, three layers of polypropylene (PP) 1.4 ~ 4.0mm. The three materials are integrated into one, and are firmly combined with the steel tube to form a good anticorrosive coating. The temperature of the anticorrosive coating can reach 110 degrees.

Diameter range from 60 to 1420GB/T23257-2009

The upper and lower limits of the thickness of the film. According to the regulation of table 2.0.2 in the SY/T0413-2002 standard, it is 170-250 u m, and this thickness is not a problem for the circular mold coating line. For the winding operation line, this thickness can not guarantee the actual grafting glue of the 3PE anticorrosion adhesive in our country. The copolymer is actually a 3PE anti-corrosion first band adhesive. The product of acrylic anhydride grafting, so it should be called graft adhesive more appropriate; the current industry standard SY / T0413-2002 four items of confocal tar. The adhesive wrapped in epoxy powder on the middle of the steel tube is beneficial to the adhesion between the steel pipe and PE.

Polyethylene is mainly high density polyethylene (HDPE), and the softening point of VEKA is not less than 110 C, and the thickness of the high temperature area not more than 220 degrees is determined by the German standard DIN30670-1991, which is mainly low and medium density polyethylene. The impact strength of 3PE anticorrosion layer is greatly improved and the quality of pipeline construction is guaranteed. SY/T0413-2002 also greatly improves the peeling strength and impact resistance of the 3PE anticorrosion layer, and clearly stipulates the carbon black content of some special materials, which ensures the mechanical strength and the touch performance of the 3PE anticorrosion layer, and increases the peeling strength of the patch. (i.e. the peeling strength of primer steel with heat shrinkage sleeve and heat shrinkage belt) sampling frequency has contributed to guaranteeing the quality of external anticorrosive coating of pipeline.

- Q: Are composite pipes resistant to soil settlement?

- Yes, composite pipes are generally resistant to soil settlement. The materials used in composite pipes, such as fiberglass or carbon fiber reinforced polymers, have excellent strength and stiffness properties, which enable them to withstand soil settlement without significant deformation or damage. Additionally, composite pipes are typically designed to have a smooth inner surface, which minimizes the accumulation of soil and prevents settlement-related issues.

- Q: What are the differences between the two types of lean composite pipes?

- Aluminum plastic pipe: aluminum plastic composite pipe is a more popular pipe in the market, because of its light weight, durability and convenient construction, its flexibility is more suitable for use in home improvement. The main drawback is that when used as a hot water pipe, due to long-term thermal expansion and cold contraction, it will cause the wall of the pipe to be dislocated so as to cause leakage.

- Q: Can composite pipes be used for landfill leachate collection?

- Yes, composite pipes can be used for landfill leachate collection. Composite pipes are made of different materials such as fiberglass, plastic, and other reinforcing fibers, making them highly resistant to corrosion, chemicals, and abrasion. These properties make them suitable for handling the corrosive and potentially harmful leachate fluids generated in landfills. Additionally, composite pipes have a smooth inner surface, minimizing buildup and allowing for efficient flow of leachate.

- Q: Are composite pipes suitable for use in mining operations?

- Yes, composite pipes are suitable for use in mining operations. Composite pipes offer several advantages such as high strength, corrosion resistance, and durability, making them ideal for conveying various fluids and materials in the mining industry. Additionally, their lightweight nature reduces installation and maintenance costs while enhancing overall efficiency and safety in mining operations.

- Q: PE pipe and steel plastic composite pipe how connected together

- DN DN is actually a diameter, diameter, PE pipe and steel plastic composite pipe diameter are unified, as long as you say DN150 and dn160 on the line, the most secure way is connected with flange. If the medium pressure is not high input can use the hoop

- Q: Are composite pipes resistant to thermal expansion?

- Yes, composite pipes are generally resistant to thermal expansion. The combination of materials used in composite pipes, such as fiberglass and epoxy resin, provides them with a high degree of dimensional stability, allowing them to withstand the effects of thermal expansion and contraction.

- Q: Are composite pipes suitable for use in residential plumbing?

- Yes, composite pipes are suitable for use in residential plumbing. They are lightweight, corrosion-resistant, and have a longer lifespan compared to traditional materials like metal or PVC. Composite pipes also offer better insulation, reducing heat loss and noise transmission. Additionally, they are easy to install, maintain, and have a lower risk of leaks.

- Q: PSP plastic steel pipe and lining plastic pipe difference

- As the name suggests is lining plastic pipe in the pipe wall lining a layer of plastic, for the purpose of internal corrosion of steel pipe, but as a senior sales staff, the deaf ears furnishings still can be divided clearly, pipe lined with plastic for wire, tube wall has plastic layer, but the pipe with a connection, the inner wall of the pipe the plastic layer and the middle layer plastic pipe wall cracks can not reach the requirement of water resistance, a long time will cause the plastic layer and the steel layer from the water can not circulate time wall middle long will breed bacteria instead of water pollution.

- Q: What is the chemical resistance of composite pipes?

- Composite pipes generally have excellent chemical resistance due to their construction materials, which often include a combination of resins, fibers, and additives. These materials are carefully selected to withstand a wide range of chemicals, acids, bases, and solvents. Additionally, composite pipes are less prone to corrosion and offer superior resistance to chemical degradation compared to traditional metal or plastic pipes. However, the specific chemical resistance may vary depending on the composition and design of the composite pipe, making it crucial to refer to the manufacturer's specifications and compatibility charts for accurate information regarding the resistance to specific chemicals or substances.

- Q: Can composite pipes be used for irrigation pivots?

- Yes, composite pipes can be used for irrigation pivots. Composite pipes are made from materials such as fiberglass or plastic, which are lightweight and corrosion-resistant. These properties make them well-suited for use in irrigation systems, including pivots. Composite pipes have high strength-to-weight ratios, allowing for easy installation and maneuverability of the irrigation pivot system. Additionally, composite pipes have a longer lifespan compared to traditional materials like metal, reducing maintenance and replacement costs.

Send your message to us

Composite Strengthening Grade 3PE Anticorrosion Gas Pipeline 3PE Anticorrosion Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 655 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches