Natural gas pipeline 3pe anti-corrosion steel pipe manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 443 m²

- Supply Capability:

- 56655 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

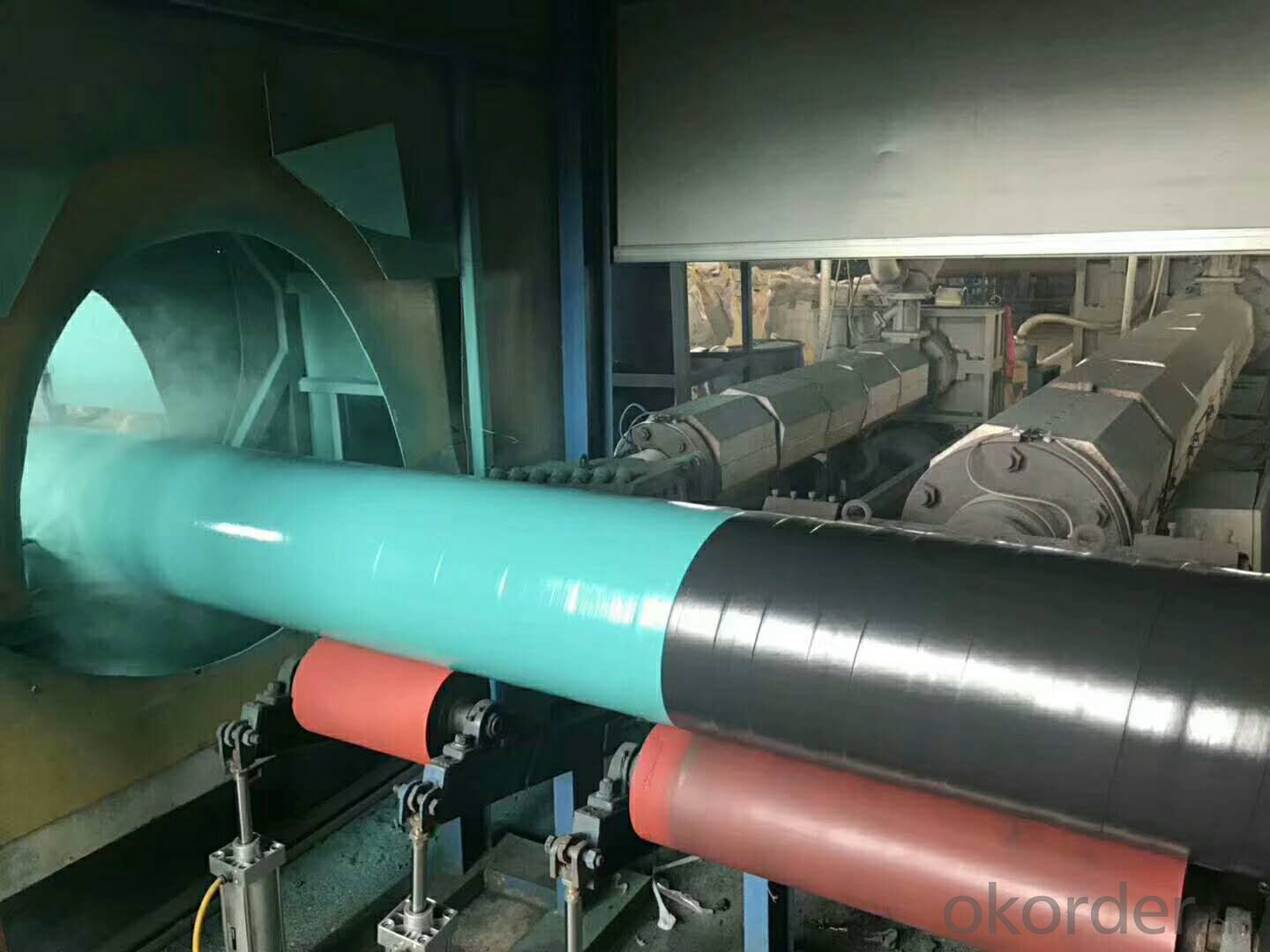

3 PE anticorrosive pipe

The 3PE epoxy powder composite steel pipe (also known as TPEP anti-corrosion pipe) is an upgrade product on the basis of the epoxy composite steel pipe in the outer polyethylene, which is the most advanced anti-corrosion form of buried long distance pipeline at present. The self-developed fourth-generation large-diameter pipeline's new anti-corrosion outer wall adopts thermal fusion and winding process to form a three-layer structure anti-corrosion layer with the bottom epoxy resin, the middle adhesive and the outer polyethylene. The inner wall adopts thermal spraying epoxy powder for anti-corrosion, and the powder is evenly coated on the surface of the pipe body after being heated and melted at high temperature. At the same time, it has high strength of epoxy, low water absorption of PE and good softness of hot melt adhesive, with high anti-corrosion reliability.

1 at the end of glue. Before extruding the polyethylene coating, a sealing rubber layer should be applied to the pipe surface. The performance index of base gum is based on the hot melt adhesive of asphalt type used before. National standards on the base of the softening point, heating loss, needle penetration, thermal decomposition temperature, self-repair, shear strength, peel strength, and so on. However, it is proved that the adhesive still has many disadvantages, such as low temperature resistance and poor bonding performance. Some foreign people use butyl glue and the latest resin glue, and domestic base glue is one of the key research topics.

2 polyethylene. The density of polyethylene can range from 0, 91 to 0, 96g /c. The performance is different because of the different densities. Since there is no short bifurcation in high density polyethylene, its junction bii, degree, secondary strength, fracture rate, tear strength, drug resistance is much better than low density polyethylene, which can produce corrosion coatings with different properties and different prices according to the needs of users. High density polyethylene coated pipe (Huang Jiake) the applicable temperature below so ℃, bottom density polyethylene coated pipe (green jacket) the applicable temperature below 60 ℃.

3. Production method. Polyethylene anticorrosive coating used flow dipping process and powder dispersing and melting process, etc. Recently, the production method is basically extrusion method. Bibian of small diameter (15-800mm) is the adhesive circular mould method (with protective layer), and bibian of human diameter (400-1600mm) is the tight t-mould method (no protective layer, single layer). Recently, the use of close - fitting method on small and medium diameter pipe is increasing gradually. In the future, this method may be widely used on anti-corrosion steel pipe

- Q: Can steel pipes be used for underground sewer systems?

- Yes, steel pipes can be used for underground sewer systems. Steel pipes are known for their durability, strength, and resistance to corrosion, making them a suitable choice for underground applications such as sewer systems. However, it is important to consider factors like soil conditions, potential for corrosion, and local regulations before selecting steel pipes for an underground sewer system.

- Q: How do you calculate the pipe volume for steel pipes?

- To calculate the volume of a steel pipe, you need to know its length and the inner diameter of the pipe. The formula to calculate the volume of a cylindrical shape, like a pipe, is V = πr^2h, where V is the volume, π is a mathematical constant approximately equal to 3.14159, r is the radius of the pipe (which is half of the inner diameter), and h is the length of the pipe. Firstly, measure the inner diameter of the pipe using a measuring tape or a caliper. Divide this value by 2 to obtain the radius. Next, measure the length of the pipe in either inches, feet, or meters. Ensure that you use the same unit of measurement for both the radius and length. Once you have the radius and length, plug them into the formula V = πr^2h. For example, let's say the inner diameter of the steel pipe is 10 inches and the length is 50 feet. First, divide the inner diameter by 2 to find the radius: 10 / 2 = 5 inches. Next, convert the length to inches: 50 feet * 12 inches/foot = 600 inches. Now, plug the values into the formula: V = 3.14159 * 5^2 * 600. Calculating the volume: V = 3.14159 * 25 * 600 = 47,123.85 cubic inches. Therefore, the volume of the steel pipe is approximately 47,123.85 cubic inches.

- Q: What is the elasticity of steel pipes?

- Steel pipes exhibit elasticity, which allows them to undergo deformation when external forces are applied and regain their original shape once the force is no longer present. The high elasticity of steel pipes is well-known, as it enables them to endure different types of stress and strain without suffering permanent deformation. This characteristic is vital in situations where pipes experience pressure, bending, or other mechanical forces. The elasticity of steel pipes is determined by material properties like its Young's modulus, which quantifies its stiffness and capacity to resist deformation.

- Q: How do you calculate the pipe volume flow rate for steel pipes?

- In order to determine the volume flow rate of steel pipes, one must take into account the diameter of the pipe and the velocity of the fluid. The formula utilized in this calculation is Q = A * V, where Q represents the volume flow rate, A denotes the cross-sectional area of the pipe, and V represents the fluid velocity. To initiate the process, the cross-sectional area of the pipe must be determined. In the case of a circular pipe, the formula A = π * r² can be employed, where A signifies the area and r denotes the radius of the pipe. If the diameter of the pipe is provided, dividing it by 2 will yield the radius. Subsequently, the fluid velocity must be established. This can be accomplished by directly measuring the velocity using a flowmeter or by calculating it based on the properties of the fluid and the pressure drop across the pipe using the Bernoulli equation or other suitable equations. Once the cross-sectional area and fluid velocity have been determined, they can be multiplied together to ascertain the volume flow rate. It is important to maintain consistent units throughout the calculation. For instance, if the area is expressed in square meters and the velocity is in meters per second, the resulting volume flow rate will be in cubic meters per second. It is worth noting that this calculation assumes the fluid to be incompressible and flowing steadily through the pipe. If there are alterations in the fluid properties or flow conditions, additional considerations may need to be taken into account in order to accurately calculate the volume flow rate.

- Q: What are the common applications of steel pipes in construction?

- Steel pipes are commonly used in construction for various applications such as structural supports, plumbing systems, gas and water distribution, and underground utilities. They provide strength, durability, and resistance to corrosion, making them suitable for both above-ground and underground installations.

- Q: What are the different sizes of steel pipes available?

- Steel pipes are available in a wide range of sizes, varying from small diameter pipes used for plumbing applications to large diameter pipes used for industrial purposes. The sizes typically range from 1/8 inch to 72 inches in diameter, with various wall thickness options.

- Q: What does "spiral welded steel pipe" DN325*10 mean?

- Spiral welded steel pipe with nominal diameter of 325mm and wall thickness of 10mm

- Q: What are the different types of threading on steel pipes?

- There are several different types of threading commonly used on steel pipes, including tapered, parallel, and buttress threading. Tapered threading is typically used for pipes that require a tight seal, as the threads gradually narrow towards the end of the pipe. Parallel threading, on the other hand, has threads that run parallel to the pipe's axis and is often used for pipes that need to be easily assembled and disassembled. Buttress threading is a combination of tapered and parallel threading, featuring one side with a tapered thread and the other side with a straight thread. This type of threading is often used for pipes that require both a secure connection and easy installation.

- Q: 25 of the steel pipe with 6 in charge of what is the difference?

- Outer diameter representation of steel pipe:When the design is nominal diameter DN means diameter, should be nominal diameter DN and the corresponding product specifications table. Specification for unplasticized polyvinyl chloride pipes for building drainage, de (nominal outer diameter) * e (nominal wall thickness), (GB, 5836.1-92), polypropylene (PP) pipe for water supply, specifications by de * e (nominal outer diameter * wall thickness).

- Q: Are steel pipes fire resistant?

- Yes, steel pipes are considered fire resistant due to their high melting point and ability to withstand extreme heat.

Send your message to us

Natural gas pipeline 3pe anti-corrosion steel pipe manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 443 m²

- Supply Capability:

- 56655 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords