Steel-work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

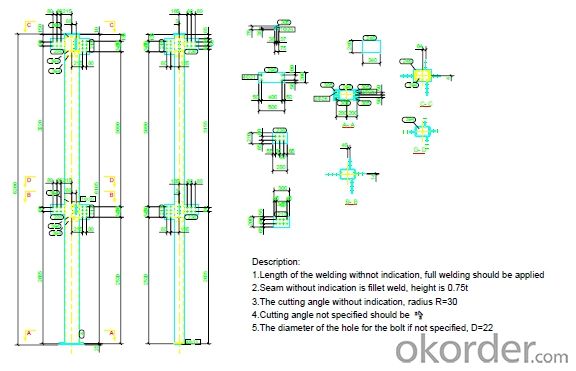

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: How much is the square metre of steel structure engineering cost now?

- As we all know, the cost of the steel structure house is basically the same as that of the traditional concrete structure, but the use area can be more than 5%, and the average carbon emission should be about 35% lower. It is an ideal choice for the development of a low carbon economy.Light steel structure residential structure refers to the use of steel structure as load-bearing structure, with environmental protection, light body, energy-saving materials for residential structures. At present, the light steel structure in China's construction industry accounted for less than 5%, while Europe and the United States and Japan developed countries have reached more than 50%. The development of residential steel structure in our country is very large.

- Q: How do steel structures contribute to the overall sustainability of a building?

- There are several ways in which steel structures enhance the overall sustainability of a building. To begin with, steel possesses exceptional durability and a long lifespan. Consequently, steel structures necessitate less maintenance and replacement over time in comparison to alternative building materials. This durability diminishes the requirement for regular repairs and renovations, thereby decreasing the overall environmental impact of the building. Furthermore, steel is a recyclable material. At the conclusion of a building's life cycle, it is effortless to dismantle steel structures and recycle the steel for alternative purposes. This reduces the quantity of waste generated during the demolition process and minimizes the depletion of natural resources. Moreover, steel structures present design flexibility, permitting efficient utilization of space and the capability to adapt to changing needs. This flexibility implies that buildings can be easily modified or expanded without extensive demolition or reconstruction. Consequently, construction waste is reduced, contributing to the overall sustainability of the building. Additionally, steel is a lightweight material when compared to other construction materials like concrete. This lightweight characteristic facilitates easier transportation and assembly, resulting in reduced energy consumption during construction and minimized carbon emissions during transportation. Lastly, steel structures possess high resistance to fire, earthquakes, and other natural disasters. By providing a secure and safe environment, steel structures increase a building's longevity and reduce the necessity for reconstruction following a disaster. This resilience minimizes the environmental impact of rebuilding and decreases the risk to human life, thus contributing to the overall sustainability of the building. In conclusion, steel structures enhance the overall sustainability of a building due to their durability, recyclability, design flexibility, lightweight nature, and resilience. By selecting steel as a building material, we can construct structures that are not only environmentally friendly but also cost-effective and safe for occupants.

- Q: How are steel structures used in the construction of theaters?

- Steel structures are commonly used in the construction of theaters due to their strength, flexibility, and cost-effectiveness. Steel beams and columns provide a sturdy framework, allowing for large open spaces without the need for excessive support walls. This enables architects to design grand auditoriums with unobstructed views for the audience. Additionally, steel can be easily fabricated off-site, reducing construction time and costs. Its durability also ensures the safety and longevity of the theater, making it a popular choice in modern theater construction.

- Q: What are the considerations when designing steel structures for oil and gas refineries?

- When designing steel structures for oil and gas refineries, several considerations need to be taken into account. Firstly, the structures must be able to withstand extreme weather conditions, such as high winds, heavy rain, and potential earthquakes. Additionally, they should be designed to accommodate the weight of the equipment and machinery used in refining processes. Another crucial consideration is corrosion resistance, as oil and gas refineries often operate in corrosive environments. The structures must have proper coatings and materials to prevent corrosion and extend the lifespan of the facility. Safety is also paramount, so designing structures that can withstand potential explosions or fires is essential. Lastly, the flexibility to accommodate future expansion or modifications is important since refineries may need to adapt to changing demands or technologies. Overall, the design of steel structures for oil and gas refineries requires a comprehensive understanding of the industry's specific requirements and a focus on safety, durability, and adaptability.

- Q: What is the role of steel in cultural and recreational buildings?

- Steel plays a crucial role in cultural and recreational buildings, serving both functional and aesthetic purposes. Firstly, steel is widely used in the construction of these buildings due to its high strength-to-weight ratio. This property allows architects and engineers to design large, open spaces, such as auditoriums, exhibition halls, or sports arenas, without the need for excessive columns or support structures. Steel's ability to span long distances helps create expansive interiors, providing flexibility in layout and accommodating various activities or exhibits. Additionally, steel's flexibility allows for unique architectural designs and iconic structures that become cultural landmarks. From the Eiffel Tower to the Sydney Opera House, steel has been instrumental in shaping the character and identity of cultural buildings around the world. Its malleability enables the creation of intricate and imaginative shapes, making it a favored material for creating visually striking and memorable structures. Moreover, steel's durability and resistance to fire, earthquakes, and other natural disasters ensure the safety and long-term sustainability of cultural and recreational buildings. This is particularly important as these buildings often host large crowds and house valuable cultural artifacts or equipment. Furthermore, steel's recyclability and sustainability make it an environmentally friendly choice for construction. The ability to recycle steel reduces the need for raw materials and minimizes the carbon footprint associated with the construction industry. In summary, steel's strength, versatility, and aesthetic appeal make it an indispensable material in cultural and recreational buildings. Its use allows for the construction of large, open spaces, iconic designs, and safe and sustainable structures that contribute to the cultural and recreational experiences of individuals and communities.

- Q: What are the different types of steel coatings used for protection?

- There exist various steel coatings that are commonly utilized for protective purposes. These coatings offer different levels of defense against corrosion, wear and tear, and other environmental factors. Some of the most frequently employed steel coatings are as follows: 1. Galvanized Coatings: The process of galvanization entails coating steel with a layer of zinc. This particular coating exhibits exceptional resistance against corrosion and safeguards the steel from rusting. Galvanized coatings are extensively utilized in outdoor applications like fences, guardrails, and metal roofs. 2. Powder Coatings: Powder coatings are a popular preference for steel protection owing to their durability and versatility. These coatings comprise finely ground particles, typically a polymer resin, which are electrostatically sprayed onto the steel surface. Subsequently, the coated steel is heated, causing the powder to melt and form a protective layer. Powder coatings offer excellent resistance against corrosion, chemicals, and UV rays. 3. Epoxy Coatings: Epoxy coatings are renowned for their high resistance against corrosion, chemicals, and abrasion. These coatings consist of a two-component system, comprising epoxy resin and a hardener. Epoxy coatings find frequent usage in industrial environments, such as pipelines, tanks, and machinery, where protection against harsh conditions is crucial. 4. Polyurethane Coatings: Polyurethane coatings deliver outstanding protection against corrosion, chemicals, and abrasion. They are commonly employed in applications that demand a high level of durability and resistance, like bridges, marine structures, and automotive components. Moreover, polyurethane coatings possess good UV resistance, making them suitable for outdoor usage. 5. Ceramic Coatings: Ceramic coatings are highly regarded for their exceptional heat resistance and durability. These coatings are composed of inorganic materials, such as aluminum oxide or zirconium oxide, which are applied to the steel surface using thermal spray techniques. Ceramic coatings are frequently utilized in high-temperature applications, including exhaust systems, turbines, and aerospace components. It is crucial to carefully select the appropriate steel coating based on the specific requirements of the application. Factors such as the desired level of protection, the environmental conditions in which the steel will be utilized, and the desired lifespan of the coating should all be taken into consideration when determining the most suitable type of coating.

- Q: How is steel fabricated for construction purposes?

- When it comes to steel fabrication for construction, there are several steps that are typically involved. To begin with, the necessary raw materials for steel fabrication, such as iron ore, coal, and limestone, are gathered. These materials are then processed in a blast furnace to create molten iron. In order to achieve the desired properties of the final product, the molten iron is mixed with recycled steel and other alloys. Once the molten steel has been obtained, it is poured into molds to create ingots or billets. These initial shapes are then heated and rolled in a process called hot rolling. This involves passing the steel through a series of rollers to achieve the desired dimensions and form various structural shapes like beams, columns, and plates. After hot rolling, the steel undergoes several additional processes to refine its properties. One common method is heat treatment, where the steel is subjected to controlled heating and cooling to enhance its strength and hardness. Additionally, surface treatments like galvanizing or painting may be applied to protect the steel from corrosion. The final step in steel fabrication for construction is cutting and shaping the steel to fit the specific requirements of the project. This is typically done using specialized machines like saws, drills, and plasma cutters. Welding is also commonly utilized to join different pieces of steel together. In summary, steel fabrication for construction involves a combination of mining, smelting, rolling, heat treatment, and shaping processes. These processes work together to produce high-quality steel products that meet the structural needs of various construction projects.

- Q: How are steel structures designed for soil-structure interaction?

- Steel structures are designed for soil-structure interaction by considering the properties and behavior of the soil as well as the structural requirements. Engineers analyze the soil characteristics such as its bearing capacity, settlement, and lateral resistance to determine the loads that the structure will experience. This information is then used to design appropriate foundation systems, including footings or piles, that can distribute the loads from the steel structure to the soil effectively. By understanding and accounting for the interaction between the steel structure and the soil, engineers can ensure the stability, safety, and performance of the overall system.

- Q: How are steel structures used in pulp and paper mills?

- Steel structures are widely used in pulp and paper mills for their strength, durability, and ability to withstand harsh industrial conditions. They are used to support heavy machinery, equipment, and conveyors systems, ensuring efficient and safe operations. Additionally, steel structures are used for storage facilities, maintenance buildings, and office spaces within the mills. Overall, steel structures play a crucial role in providing the necessary infrastructure for pulp and paper production.

- Q: What are the design considerations for steel automotive plants?

- Design considerations for steel automotive plants revolve around creating a safe and efficient manufacturing facility that can meet the high demands of the automotive industry. Some key considerations include: 1. Facility Layout: The layout of the plant should be designed to optimize workflow, minimize material handling, and promote efficient production processes. This includes ensuring a smooth flow of materials, adequate space for equipment and machinery, and clear pathways for workers. 2. Structural Integrity: Steel plants require a strong and durable structure to support heavy machinery, overhead cranes, and storage of raw materials. The design should account for the weight and load-bearing capacity of the equipment, as well as factors like seismic activity and extreme weather conditions. 3. Safety Measures: Safety is paramount in automotive plants, and the design should incorporate safety features such as fire protection systems, emergency exits, proper ventilation, and the use of non-combustible materials. Additionally, ergonomic considerations should be made to minimize the risk of workplace injuries and ensure a safe working environment for employees. 4. Energy Efficiency: As the automotive industry moves towards sustainability, energy efficiency is a significant design consideration. Incorporating energy-saving features such as LED lighting, efficient HVAC systems, and renewable energy sources can help reduce operational costs and environmental impact. 5. Environmental Considerations: Steel plants often have a significant environmental footprint, so designing with sustainability in mind is crucial. This might involve implementing waste management systems, water recycling processes, and green building materials to minimize the impact on the surrounding ecosystem. 6. Flexibility and Future Expansion: Automotive manufacturing is a dynamic industry, and plant designs must be flexible to accommodate changes in production processes and technological advancements. Additionally, the design should consider the potential for future expansion or reconfiguration to meet the demands of a growing market. 7. Integration of Technology: Incorporating advanced technologies such as automation, robotics, and data analytics systems can enhance efficiency and productivity in automotive plants. The design should account for the integration and placement of these technologies to optimize their benefits. In conclusion, the design considerations for steel automotive plants encompass a range of factors, including facility layout, structural integrity, safety, energy efficiency, environmental sustainability, flexibility, and the integration of technology. A well-designed plant that addresses these considerations can provide a competitive advantage in the automotive industry while ensuring a safe and productive working environment.

Send your message to us

Steel-work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords