Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Round Bar S355J2G3 Forged Round Steel

Product Information:

1.S355J2G3 forged round bar

2.size:280*5300mm

3.ut:sep1921-84D/d

4.heatreatment:annealed

5.straightness:2mm/m

6.Process: EAF+LF+VD (ESR furnace for optional)

7.Delivery condition: Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining

8.Technical Data: Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement

9.Test: Ultrasonic and magnetic test according to customer' require(EN or ASME and so on).

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

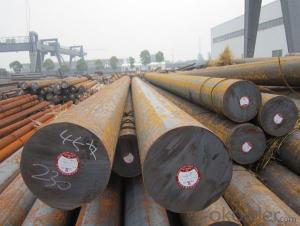

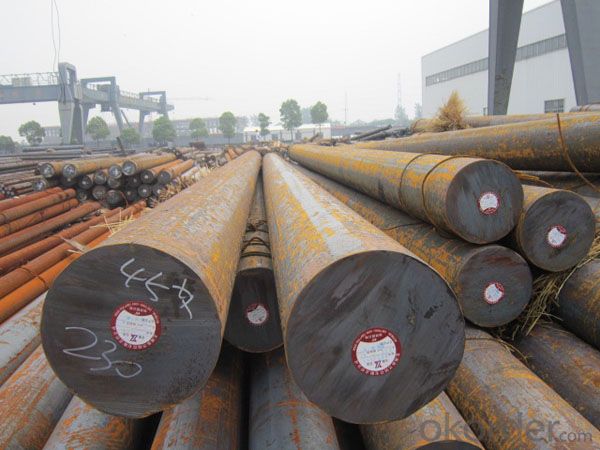

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: How does special steel maintain its strength at different temperatures?

- Special steel maintains its strength at different temperatures due to its unique composition and heat treatment process. It is alloyed with elements like chromium, nickel, and molybdenum, which form stable compounds at high temperatures, preventing the steel from losing its strength. The heat treatment process involves carefully controlling the cooling rate, which further enhances the steel's microstructure and ensures its strength is retained even at extreme temperatures.

- Q: How is special steel used in the production of precision tools?

- Special steel is used in the production of precision tools due to its unique properties such as high hardness, wear resistance, and excellent dimensional stability. These qualities make special steel ideal for manufacturing tools that require high precision, such as drills, milling cutters, and lathe tools. The use of special steel in precision tool production ensures the durability and longevity of the tools, allowing them to maintain their accuracy over time, resulting in high-quality and precise machining operations.

- Q: What are the different heat-resistant grades of special steel?

- There are several heat-resistant grades of special steel that are specifically designed to withstand high temperatures and thermal stress. Some of the commonly used heat-resistant grades include: 1. Stainless Steel 310: This grade of stainless steel is known for its excellent resistance to high temperatures, oxidation, and corrosion. It can withstand temperatures up to 1100°C (2012°F) and is often used in furnace parts, heat treatment baskets, and other heat-intensive applications. 2. Inconel 600: Inconel 600 is a nickel-chromium alloy that offers exceptional resistance to high temperatures and oxidation. It can operate effectively in temperatures ranging from cryogenic to 1093°C (2000°F) and is widely used in gas turbines, heat exchangers, and other high-temperature environments. 3. Hastelloy C-276: Hastelloy C-276 is a nickel-molybdenum-chromium alloy that offers excellent resistance to a wide range of corrosive environments and high temperatures. It can withstand temperatures up to 1093°C (2000°F) and is commonly used in chemical processing, power generation, and pollution control applications. 4. Titanium Grade 2: Titanium Grade 2 is a commercially pure titanium alloy that exhibits good resistance to high temperatures and corrosion. It can operate effectively in temperatures up to 538°C (1000°F) and is often used in heat exchangers, chemical processing equipment, and marine applications. 5. Alloy 617: Alloy 617 is a nickel-chromium-cobalt-molybdenum alloy that offers exceptional strength and resistance to high-temperature environments. It can withstand temperatures up to 1204°C (2200°F) and is commonly used in gas turbines, petrochemical plants, and other heat-intensive industries. These are just a few examples of the heat-resistant grades of special steel available in the market. The selection of the appropriate grade depends on the specific temperature requirements, corrosion resistance, and mechanical properties needed for the application.

- Q: How does special steel contribute to the tool manufacturing industry?

- Special steel plays a crucial role in the tool manufacturing industry by providing enhanced strength, durability, and wear resistance to tools. This type of steel is specifically designed to withstand extreme conditions and heavy usage, allowing tools to perform efficiently and last longer. With its unique properties, special steel enables the production of high-quality, precision tools that can handle demanding tasks in various industries, ultimately enhancing productivity and ensuring safety for workers.

- Q: What are the requirements for special steel used in cryogenic applications?

- To ensure optimal performance and reliability in extremely low-temperature environments, special steel employed in cryogenic applications must fulfill a range of prerequisites. First and foremost, the steel must exhibit exceptional low-temperature toughness, enabling it to endure the extreme cold without succumbing to brittle fracture or compromising its mechanical properties. It is imperative that the steel possesses high toughness and ductility to effectively absorb impacts and prevent cracking. Moreover, the steel must possess a low coefficient of thermal expansion. This characteristic assumes significance as cryogenic applications involve substantial temperature fluctuations. A high coefficient of thermal expansion can result in dimensional instability and stress within the material. Conversely, a low coefficient of thermal expansion mitigates these effects and maintains dimensional stability. Furthermore, the steel should demonstrate low thermal conductivity. Given that cryogenic applications often entail the transfer or storage of substances at extremely low temperatures, minimizing heat transfer is essential. A low thermal conductivity aids in maintaining the desired temperature and prevents unwanted heat exchange. This aspect is particularly critical in applications where precise temperature control is paramount, such as the storage of liquefied gases. In addition, the steel must exhibit excellent corrosion resistance. Cryogenic environments can be highly corrosive, necessitating the steel's ability to withstand the detrimental effects of corrosive substances that may be present. This attribute is particularly vital in applications involving the storage or transportation of cryogenic liquids or gases. Finally, the steel should possess good weldability. Welding is often necessary to join different components or sections of the steel in cryogenic applications. Therefore, ensuring the steel's weldability is crucial to establish strong and reliable joints. In summary, the requirements for special steel used in cryogenic applications encompass exceptional low-temperature toughness, a low coefficient of thermal expansion, low thermal conductivity, excellent corrosion resistance, and good weldability. Satisfying these requirements guarantees the steel's ability to withstand the harsh conditions and extreme cold of cryogenic environments while preserving its structural integrity and performance.

- Q: What are the limitations of using special steel in high-stress applications?

- Using special steel in high-stress applications comes with several limitations. Firstly, the cost of special steel can be significantly higher compared to other materials, making it less feasible for projects or industries with budget constraints. Secondly, the availability and sourcing of special steel can be a challenge, leading to potential delays in production or construction timelines. This becomes problematic in high-stress applications where time is of the essence. In addition, special steel may have limitations in terms of its structural integrity. Although it is generally stronger and more resistant to wear and tear than regular steel, it still has load-bearing capacity limits. Therefore, in extremely high-stress applications, special steel may not be the most suitable choice. Moreover, working with special steel can be more difficult than working with other materials. It may require specialized equipment or techniques for cutting, welding, or shaping, thereby adding complexity and cost to the manufacturing process. Lastly, special steel may have limitations in terms of its corrosion resistance. While it is generally more resistant to corrosion compared to regular steel, it can still rust or degrade if not properly maintained or exposed to harsh environments. This is a concern in high-stress applications where the material's durability and longevity are crucial. Overall, while special steel offers many benefits in high-stress applications, it is important to carefully consider its limitations in terms of cost, availability, load-bearing capacity, workability, and corrosion resistance. These factors should be thoroughly evaluated to determine the most suitable material for a specific high-stress application.

- Q: How does special steel perform in chemical processing applications?

- Special steel is widely used in chemical processing applications due to its excellent performance and unique properties. One of the key advantages of special steel in chemical processing is its high resistance to corrosion. This type of steel is specifically designed to withstand harsh chemical environments, making it highly reliable and durable. In chemical processing applications, where corrosive substances are present, special steel provides superior protection against corrosion compared to other materials. It exhibits exceptional resistance to acids, alkalis, and various chemical compounds, ensuring the integrity and longevity of equipment and components. Moreover, special steel offers excellent mechanical properties, such as high strength and toughness, which are essential in chemical processing applications. It can withstand high temperatures, pressure, and mechanical stresses commonly encountered in these environments. Its robustness and ability to maintain structural integrity under extreme conditions make it a preferred choice for critical components like reactors, vessels, and piping systems. Special steel also contributes to the overall efficiency and safety of chemical processing operations. Its resistance to scaling and fouling reduces the risk of contamination and blockages, minimizing downtime for cleaning and maintenance. This results in improved productivity and cost-effectiveness. Furthermore, special steel is often selected for its hygienic properties, making it suitable for applications in the food and pharmaceutical industries. It is easy to clean and sanitize, ensuring the highest levels of product purity and compliance with industry regulations. In summary, special steel performs exceptionally well in chemical processing applications. Its corrosion resistance, mechanical strength, thermal stability, and hygienic properties make it an ideal choice for equipment and components, enhancing the reliability, efficiency, and safety of chemical processing operations.

- Q: What are the different impact-resistant grades of special steel?

- Impact-resistant grades of special steel refer to steel alloys that are specifically designed to withstand high impact and shock loads without fracturing or deforming. These grades of steel are commonly used in applications where resistance to impact and toughness are crucial, such as in construction, mining, automotive, and defense industries. There are several different impact-resistant grades of special steel available, each with its own unique characteristics and properties. Some of the commonly used impact-resistant grades include: 1. AR400: This grade of steel has a nominal hardness of 400 Brinell (HB) and is known for its exceptional resistance to abrasion and impact. It is often used in applications where high wear resistance is required, such as in bucket liners, crushers, and hoppers. 2. AR500: With a nominal hardness of 500 HB, AR500 steel offers even higher resistance to wear and impact compared to AR400. It is commonly used in applications involving heavy machinery, mining equipment, and armored vehicles. 3. AR600: This grade of steel has a nominal hardness of 600 HB, making it one of the toughest and most impact-resistant steels available. It is often used in applications where extreme wear resistance and durability are essential, such as in chutes, conveyors, and ballistic protection. 4. T-1: T-1 steel is a high-strength, low-alloy (HSLA) steel that offers excellent impact resistance and toughness. It is typically used in applications where high strength and toughness are required, such as in structural components, heavy equipment, and offshore drilling rigs. 5. QT or Quenched and Tempered Steels: These steels are specifically heat-treated to enhance their toughness and impact resistance. They are commonly used in applications that require a combination of high strength, toughness, and impact resistance, such as in gears, shafts, and armor plates. It is important to note that the specific impact resistance of a steel grade depends not only on its composition but also on factors such as heat treatment, fabrication techniques, and design considerations. Therefore, it is crucial to consult with steel manufacturers or experts to determine the most suitable impact-resistant grade for a particular application.

- Q: What are the main applications of special steel in the defense equipment?

- Special steel is widely used in defense equipment for its exceptional properties such as high strength, durability, and resistance to extreme conditions. Some of the main applications of special steel in defense equipment include the manufacturing of armored vehicles, tanks, submarines, and naval vessels. It is also used in the production of aircraft carriers, fighter jets, and helicopters, where its strength and resistance to corrosion are crucial. Additionally, special steel is utilized in the construction of ballistic protection systems, missile components, and firearms, enhancing their performance and ensuring their reliability in critical defense operations.

- Q: What industries commonly use special steel?

- Industries commonly using special steel include automotive, aerospace, construction, energy, and manufacturing.

Send your message to us

Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords