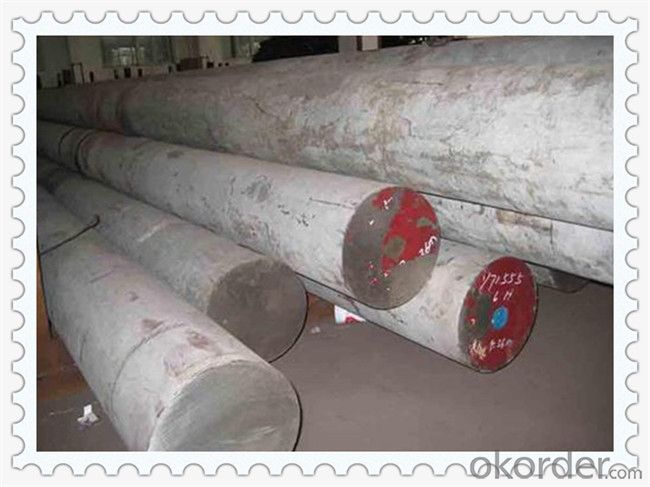

Q345B st52-3 Cr50 S355JR Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Q345B st52-3 Cr50 S355JR Steel Round Bar

1. Grade:Q345B, Q235B, SS400, HRB335, ST52-3

2. Hot-rolling

3. DIa:10-300mm

4. MOQ:20tons

5. Chemical and physical properties

Grade | C | Mn | Si | P | S | Yield Point(Mpa) | Tensile Stregth(Mpa) | Elongation (%) |

ST52-3 | ≤0.22 | ≤1.60 | ≤0.60 | ≤0.040 | ≤0.040 | ≥325 | 490 630 | ≥18 |

HRB335 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | ≥335 | ≥490 | ≥16 |

6.Size Tolerance

Length tolerance: +100mm/-0mm

Side length tolerance: +/-2mm

Straightness: max 6mm/m

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be within the limit stipulated in the contract.

We are engaged to offer wide range of steel products: steel round bar, square steel, such

as SS400B, S20C, S45C, Ck45, SAE1020B, SAE1045B, SAE4140, SAE4150, SAE4340,

SAE8620, 42CrMo4, 15B36Cr, S50C, S65C. 20Cr,40Cr.The diameter ranging from 20mm

to 300mm. Hot-rolled/forged/cold drawn.

- Q: Can steel round bars be used in the manufacturing of conveyor systems?

- Yes, steel round bars can be used in the manufacturing of conveyor systems. Steel is a strong and durable material that can withstand heavy loads and provide stability and support to conveyor systems. Steel round bars can be used as rollers or shafts in conveyor systems to facilitate the movement of materials or products along the conveyor belt. The smooth surface of the round bars allows for easy rotation and reduces friction, ensuring the smooth operation of the conveyor system. Additionally, steel round bars can be easily customized to fit specific conveyor system requirements, making them versatile and suitable for various industrial applications.

- Q: What is the typical tolerance for diameter and length in steel round bars?

- The typical tolerance for diameter and length in steel round bars can vary depending on the specific industry standards and requirements. However, in general, the tolerance for diameter in steel round bars is typically around +/- 0.005 to 0.010 inches. This means that the actual diameter of the bar can be up to 0.010 inches larger or smaller than the specified diameter. Similarly, the tolerance for length in steel round bars is usually around +/- 0.125 to 0.250 inches. This means that the actual length of the bar can be up to 0.250 inches longer or shorter than the specified length. It is important to note that these tolerances can differ based on the intended application and the specific standards set by the manufacturing industry. Therefore, it is crucial to consult the relevant industry standards or the manufacturer's specifications to determine the precise tolerances required for a particular steel round bar.

- Q: What is the maximum weight of a steel round bar?

- The maximum weight of a steel round bar depends on its diameter and length. The weight can vary from a few pounds to several tons for larger and longer bars.

- Q: Can steel round bars be used in corrosive environments?

- Steel round bars can be used in corrosive environments, but their suitability depends on the specific type of steel and the severity of the corrosion. Stainless steel round bars, for example, are known for their excellent corrosion resistance and are commonly used in corrosive environments such as marine applications, chemical processing plants, and wastewater treatment facilities. These bars are typically alloyed with elements like chromium and nickel, which form a protective layer on the steel surface, preventing corrosion. However, carbon steel round bars are more prone to corrosion and may not be suitable for highly corrosive environments without proper coatings or treatments. In such cases, it is important to consult with experts or engineers to select the appropriate steel grade and take necessary precautions to ensure the longevity and performance of steel round bars in corrosive environments.

- Q: Can steel round bars be used in the manufacturing of heat exchangers?

- Yes, steel round bars can be used in the manufacturing of heat exchangers. Steel is a commonly used material in heat exchanger construction due to its high strength and thermal conductivity. Steel round bars can be formed and welded into various shapes and sizes to create the necessary components of a heat exchanger, such as tubes, headers, and baffles. The steel material also provides durability and resistance to corrosion, making it suitable for use in various industrial applications where heat transfer is required.

- Q: Can steel round bars be used for making decorative items?

- Certainly, decorative items can indeed be created using steel round bars. With their ability to be shaped, bent, and welded, steel round bars offer a wide range of options for designing various decorative patterns. They possess durability and strength, making them suitable for both indoor and outdoor uses. Decorative furniture, sculptures, railings, gates, light fixtures, and many other items can be crafted from steel round bars. Their sleek and contemporary appearance adds an industrial and modern touch to any space. Furthermore, steel round bars can be finished with different coatings or treatments, such as powder coating or patina, to enhance their visual appeal and protect against corrosion. Consequently, steel round bars are an exceptional choice for creating decorative items because of their versatility, strength, and ability to infuse a stylish and distinctive element into any design.

- Q: What is the maximum temperature steel round bars can withstand?

- Steel round bars have varying maximum temperatures they can withstand depending on their specific grade. Nevertheless, most steel round bars generally remain structurally intact at temperatures between approximately 1000 and 1200 degrees Celsius (1832 to 2192 degrees Fahrenheit). It is worth mentioning that extended exposure to high temperatures can result in decreased strength and hardness of the steel, along with potential dimensional alterations and distortion. Moreover, the properties and behavior of steel at elevated temperatures can be influenced by factors like alloy composition, heat treatment, and the presence of other elements or impurities. If applications require steel round bars to endure exceedingly high temperatures beyond the typical range, specialized high-temperature steels like heat-resistant or creep-resistant alloys may be employed. These alloys are specifically engineered to retain their mechanical properties and structural integrity even at elevated temperatures, often reaching several thousand degrees Celsius.

- Q: What is the maximum temperature a steel round bar can withstand?

- The maximum temperature that a steel round bar can withstand depends on the specific grade and composition of the steel. Generally, most steel alloys can withstand temperatures up to around 1200°C (2200°F) before experiencing significant structural changes or loss of strength. However, it is always recommended to consult the manufacturer's specifications or engineering data for the specific steel alloy in question to determine its maximum temperature tolerance.

- Q: What are the different machining processes used for steel round bars?

- Steel round bars can be machined using various processes to achieve specific outcomes and meet project specifications. Some commonly employed machining processes for steel round bars include the following: 1. Turning: By rotating the round bar and utilizing a cutting tool, material is removed to create the desired shape or size. This method is often employed to decrease the diameter or produce precise cylindrical shapes. 2. Drilling: Holes are created in the steel round bar using a rotating cutting tool called a drill bit. This process is frequently used for installing bolts, screws, or other fasteners. 3. Milling: Material is removed from the surface of the steel round bar using a rotating cutting tool with multiple teeth. This method is employed to create flat surfaces, grooves, or intricate shapes. 4. Grinding: Abrasive particles are used to remove material from the steel round bar, resulting in a smooth surface finish and achieving specific tolerances. This process is commonly used to refine the surface or eliminate imperfections. 5. Thread rolling: External threads are created on the steel round bar by pressing a hardened steel die against the rotating bar, causing the material to flow and form the desired threads. 6. Cold drawing: The steel round bar is pulled through a die, reducing its diameter and enhancing its surface finish. This process is utilized to achieve precise dimensions and improve the mechanical properties of the bar. 7. Heat treatment: Although not a machining process itself, heat treatment is often combined with machining to enhance the properties of the steel round bar. Processes like annealing, quenching, and tempering can improve hardness, strength, and toughness. These represent just a few of the numerous machining processes available for steel round bars. The selection of a specific process depends on factors such as the desired shape, size, surface finish, and mechanical properties required for the intended application.

- Q: What is the weight of a steel round bar?

- The weight of a steel round bar can vary depending on its dimensions and the type of steel used. Generally, the weight of a steel round bar can be calculated by multiplying its volume (pi times the square of the radius times the length) by the density of the steel.

Send your message to us

Q345B st52-3 Cr50 S355JR Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords