Ceiling Profile Steel Profile - Good Construction Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

3.Image

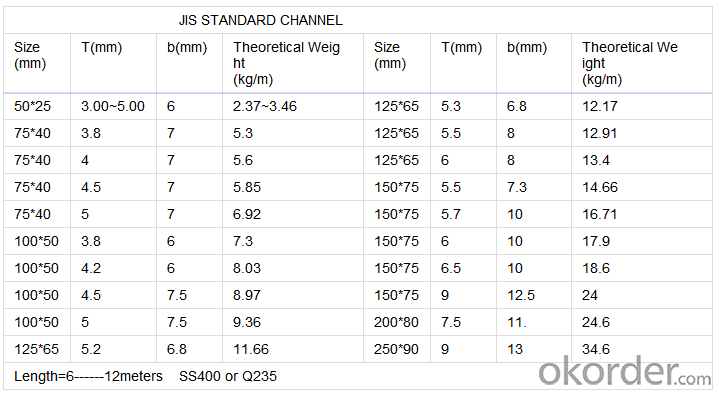

4.Detailed Specification

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

- Q: Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q: Why the ceiling keel

- Ceiling keel is what we often see the ceiling, especially the shape of the ceiling, are made of keel frame, and then covered with gypsum board made. Ceiling keel is made of light steel, for the ceiling of the main material, it is connected with the floor through the screw, used to fix the ceiling or objects.

- Q: What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- After the line with the woodworking board to open about 200mm wide oval frame (upper and lower layers) and then use 200 * 400 (height) of the wood plate around the oval to do the upper and lower layers of the two oval connected inside and then sealed 5mm board plate Hang up to shape out (drawing very good description of the painting really can not say you do not know clearly)

- Q: Light steel keel ceiling one square meter how much money

- Now on the market of light steel keel ceiling is generally 30-40 / square meter, of course, different quality keel ceiling price is not the same, and now we come to understand the light steel keel ceiling installation method!

- Q: Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel backing, after the order made with gypsum board! Grille Ceilings I feel better!

- Q: Is in accordance with the vice keel 400, the main dragon spacing 600 spacing arrangement?

- Light steel keel ceiling 400 * 600 meaning: the main keel and the distance between the main keel 600MM, vice keel and vice keel spacing of 400MM. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- I think it Cost, light steel keel is more expensive than wood keel. Light steel keel is also divided into many kinds, it is recommended to use the national standard, the National Building Materials Testing Center of the test report is the real standard. GB price is not expensive, less than 20 yuan a square meter, non-standard cheaper less than 10 yuan a square meter. Own their own projects to their own good. Or cracking, deformation problems are very troublesome, the best step in place.is better to light steel keel

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling in the wood keel spacing: 1, light steel keel: keel for the edge of the dragon, the lamp slot position with keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, gypsum Between the board and the board to be reserved for 5-8 mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to be smooth and solid, shaped to be smooth lines; 2, keel: keel at least 3 × 4 or more, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, hanging bar is strictly prohibited direct use of wood wedge nail to the top, brush tight fire paint until the keel color can not see the dragon A layer of full-legged rice eucalyptus core after nine on the gypsum board, gypsum board and the board between the people to set aside 5-8mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to do To the formation of solid, shaped to do smooth lines; 3, aluminum buckle board: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board, And the contact with the tile is not tight to use the sealant to play tight; 4, aluminum-plastic plate: keel at least 3 × 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core 9% Adhesive paste aluminum-plastic plate, aluminum-plastic plate between the board to be reserved for 3-4mm gap, prepared to fill other colors play the effect of sub-grid, to be smooth and solid, shaped to do smooth lines, folding The angle can not be broken.

- Q: Light steel keel paper gypsum board ceiling construction process

- 1. Process: Slide - → Install the big keel boom - → install the big keel - → install the keel - → install the keel - → install the cover cotton board - → install the pressure bar - → brush anti-rust paint 2. Pin line: According to the floor elevation line, with the ruler vertical volume to the top [shed design elevation, along the wall, the column around the ceiling height, and along the elevation of the ceiling line, draw a good line on the wall line. 3. Install the big keel boom: After playing the high level of the ceiling and the keel position line, determine the elevation of the lower end of the boom, press the big keel position and the hanging spacing, the boom without the end of the screw thread and the floor embedded rib Connection is fixed.

- Q: Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Light steel keel manuscript board ceiling and the need to stay between the wall, leaving 5MM is enough

Send your message to us

Ceiling Profile Steel Profile - Good Construction Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches