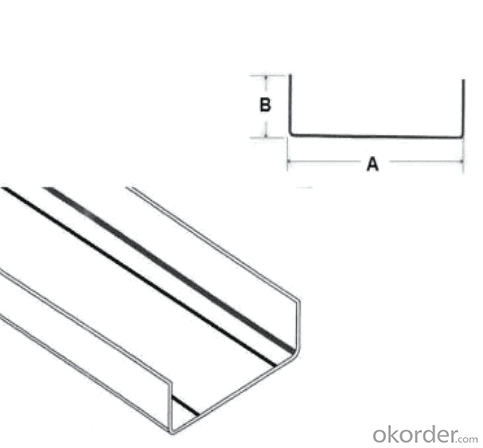

Ceiling Profile - Decorative Ceiling System Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

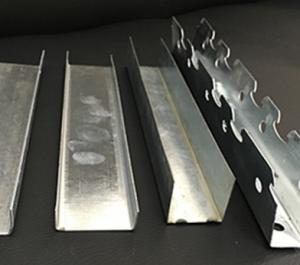

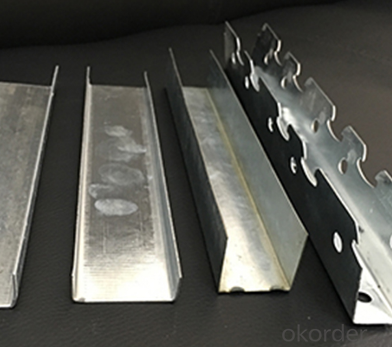

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

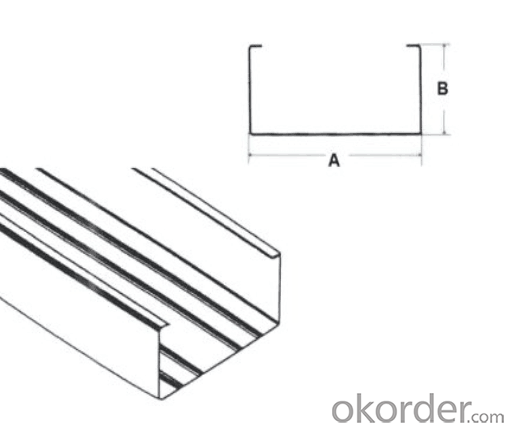

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

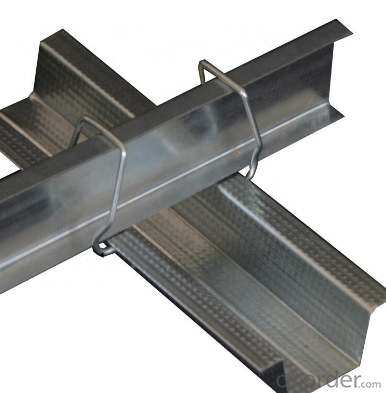

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

- Q: Light steel keel ceiling how to read complex drawings

- Do the work of the words do not matter how the light steel keel ceiling how to do a project to do in-depth understanding of the project because there are many national norms limit, how to understand the drawings, you need to have some theoretical knowledge, plus more to the site to see how workers Construction, ie theory + reality

- Q: Do not know the price of light steel keel home improvement, it is best to use the North New Building materials dragon card. Have to know the friend thread, thank you!

- For people to help done! The specific price forgotten! For the time to do with the cut off with!

- Q: What is a man ceiling, what is not a man ceiling?

- My idea is that the master name suggests, you can master, ask the high point of the tune, the keel to meet the requirements of the Master, and now sell the keel is not on the Master and Master, keel easy to repair, Learn from everyone

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 1-1.2mm thick

- Q: Tectonic levels and practices of light steel keel

- First find the ceiling of the horizontal line, and then installed in the roof on the big expansion screws. Under the boom, the distance from the boom do not exceed 80mm installation hook, and then on the 38 keel hanging with the installation of the vice keel we generally do 40mm grid, gypsum board specifications are 120mm / 3000mm. Gypsum board installation to stay, 5mm gap. Then there is adhesive powder leveling. And then stick to the bandage, in the putty putty, brush paint.

- Q: Light steel keel ceiling cad chart

- There is a special light steel keel construction of the chart to sell, you can buy a set, only tens of dollars, inside the various forms of light steel keel ceiling, partitions have detailed construction techniques and regulatory requirements

- Q: Light steel keel ceiling is not what is the price plate

- But also depends on the quality of the keel! More than 50 yuan

- Q: Light steel keel gypsum board ceiling technology

- This is based on the price, the shape of the more complex ceiling, depending on the specific circumstances to determine.

- Q: Light steel keel and wood keel ceiling unit area of the amount of material how to calculate?

- According to the ceiling area of 3 times the calculation, such as the ceiling area of 100 square meters, 300 meters keel.

Send your message to us

Ceiling Profile - Decorative Ceiling System Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords