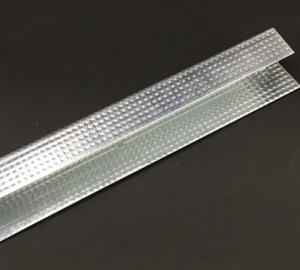

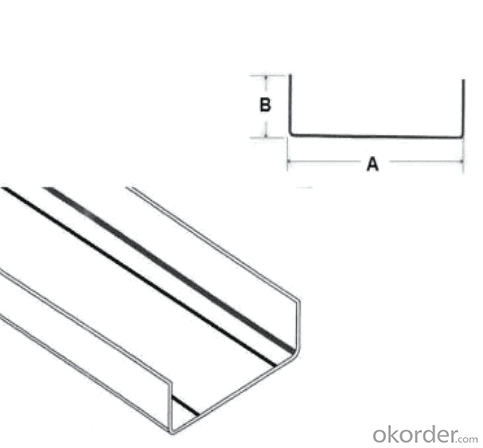

Ceiling Profile Steel Profiles for Ceiling and Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

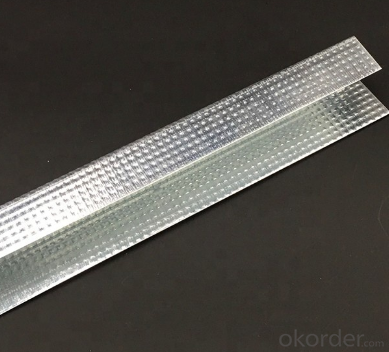

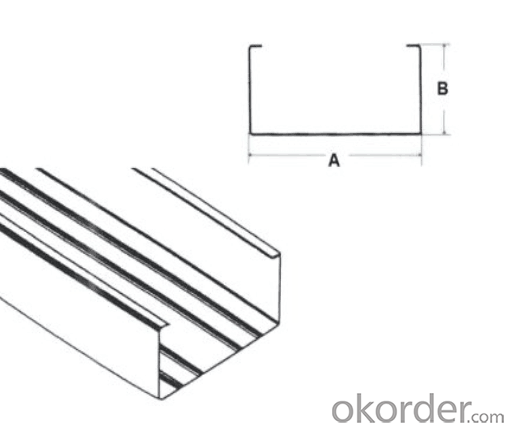

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

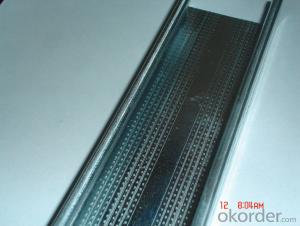

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: Light steel keel gypsum board ceiling need floor?

- Modeling more complex when the bottom of a good job, Moreover, plus the bottom plate can be more money ah. As far as possible Huayu customer plus such a greater profit it

- Q: Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Light steel keel ceiling screw must be installed vertically? There are pictures.

- So that the vertical is the most easy to pull out, you pull things are subconsciously vertical pull, the most effort. So oblique, pull even more ~

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: Light steel keel ceiling price 60 level probably need much money

- A square about a hundred or so package materials

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Plastic buckle, it should be wooden keel, is the wooden side. If it is aluminum buckle, it should be light steel keel.

- Q: Light steel keel second ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling.

- Q: Light steel keel good or fir Fang Fang dragon skeleton good

- Light steel keel is good, will not be damp, will not be deformed, but not easy to do modeling, so there are a lot of home improvement with wood keel, because it is easy to do a variety of shapes, but to brush on the moisture and fire paint. 1, according to the order of operation. 2, wood keel no knots, wood keel then long to link firmly, boom and wood keel, floor link firmly. 3, keel should be painted fire anticorrosive coating. 4, suspended keel to consider the future sagging, so after installation, the center should be short side of the arch from 1/200. 5, where a lampshade, curtain box and other positions should increase the keel, ceiling fan shall not be in the dragon on the skeleton. 6, cover the panel should be flat, no Qiaojiao, from the skin, degumming and other phenomena, if the parquet, the design should be the design requirements. Slats, steel mesh plaster top 1, wood keel grid with the wooden ceiling. 2, lath joints must be staggered, the board should not be too light, slats and steel mesh are nailed. 3, lime paste must be fully mature, do not allow lime fixed particles, so as not to plaster from the bubble after the bubble. 4, slag dry, easy to water swelling, after the plaster dry and easy to crack, so the end of the ash should be sprayed with water after wetting, and then wipe the leveling layer to combine with each other. Light steel keel ceiling 1, the selection of light steel keel should meet the design requirements to ensure quality. 2, all in the ceiling of spare parts, keel should be galvanized pieces. 3, keel, boom, connectors should be the right position, the material formation, straight, connected firmly, no loosening.

- Q: Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Landlord or light steel bar! One word: province.

- Q: Light steel keel paper gypsum board ceiling construction process

- Material purchase requirements 1. Light steel skeleton sub-U-shaped skeleton and T-skeleton two, according to the load and not on the master. 2. Light steel skeleton main pieces for large, medium and small keel; accessories hanging pendant, connectors, hanging plug. 3. Spare parts: a boom. Flower blue screws. Nail. Self-tapping screws. 4. According to the design can choose a variety of cover panels. Aluminum pressure or plastic pressure every bar, the material varieties. Specifications. Quality should meet the design requirements. 5. Binder: should be selected according to the performance of the main material, before use for bonding test.

Send your message to us

Ceiling Profile Steel Profiles for Ceiling and Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords