Steel Plate Lowest Price for Astm A36 carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of steel plate:

Our products into high-strength low-alloy steel plate, carbon structural steel plate, alloy structural steel plate, boiler and pressure vessel steel plate, bridge steel plate, structural steel plate, shipbuilding steel plate and marine oil platform steel plate, pipe steel plate, high strength and high toughness steel plate, mold plate, corrosion-resistant plate, Wear-resistand steel plate, composite plate with 12 major series.

2.Size range: Steel Plate width 300-5000mm, thickness 5-600mm, length 1000-18000mm.

Usage: (1).used for metallurgical, mechanical, electrical construction field

(2).used for ships, military (armored) Construction

(3).used for outside engineering, machine tool base, automobile rear of products

3.Standard: According to user requirements, can be delivered the following criteria: National standards, the metallurgical industry, the American ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board.

4.Inspection Standard: In accordance with China (JB4730, GB/T2970), United States (A435, A577, A588), Japan (JISG0801, JISG0901), Germany (SEL072), British (BS5996), France (NFS04-305) and other domestic and international testing standard production test.

5.Data of steel sheet:

Chemical Requirements

| N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5-6.75 | 3.5-4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2-4.0 | 0.6-0.9 | bal |

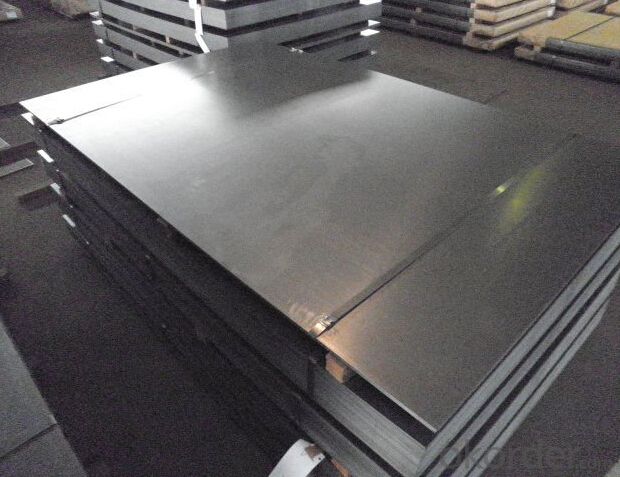

6.Image of steel sheet:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel sheets protected during cutting and fabrication?

- To ensure the quality and prevent damage, various methods are employed to protect steel sheets during cutting and fabrication. One widely used approach is galvanizing, which entails applying a zinc coating to the surface of the steel sheet. This zinc coating acts as a barrier against corrosion and other forms of harm, making it particularly effective in outdoor settings where steel sheets are exposed to moisture and harsh elements. Another technique for safeguarding steel sheets during cutting and fabrication involves the use of lubricants or coolants. These substances are applied to both the cutting tools and the steel sheet itself to reduce friction and minimize heat generation. By doing so, lubricants and coolants help prevent warping and distortion of the steel sheet during the cutting and fabrication process. Moreover, protective films or tapes are often utilized during the fabrication of steel sheets. These films or tapes shield the sheets from scratches, abrasions, and other physical damage that may occur during handling or transportation. In addition to these methods, proper handling and storage practices play a crucial role in protecting steel sheets during cutting and fabrication. It is essential to store the sheets in a controlled environment to prevent exposure to damaging elements such as moisture and extreme temperatures. Additionally, they should be handled with care to avoid impacts or bending that could compromise their structural integrity. In summary, steel sheets are protected during cutting and fabrication through the combined use of surface coatings, lubricants or coolants, protective films or tapes, and proper handling and storage practices. These measures ensure the quality and durability of the sheets, allowing them to maintain their integrity throughout the fabrication process and beyond.

- Q: Can the steel sheets withstand extreme temperatures?

- Steel sheets are known for their high durability and strength, making them suitable for various applications. When it comes to extreme temperatures, steel sheets generally have a high melting point and can withstand high temperatures without losing their structural integrity. However, it is important to note that the exact temperature limit depends on the specific type and grade of steel being used. For example, stainless steel sheets have a higher resistance to heat compared to carbon steel sheets. Additionally, factors such as the duration of exposure to extreme temperatures and the presence of other environmental factors may also influence the steel sheets' performance. Therefore, it is crucial to consider these factors and consult with experts or refer to specific product specifications to determine if a particular steel sheet is suitable for a specific extreme temperature application.

- Q: Are steel sheets suitable for exterior facade systems?

- Yes, steel sheets are suitable for exterior facade systems. Steel is a durable and versatile material that provides strength and stability to the facade. It offers excellent resistance to harsh weather conditions and requires minimal maintenance. Additionally, steel sheets can be customized in various shapes, sizes, and finishes, allowing for endless design possibilities and architectural creativity.

- Q: What are the insulation properties of steel sheets?

- Compared to other commonly used insulation materials like fiberglass or foam, steel sheets have relatively poor insulation properties. This is because steel is an excellent conductor of heat and electricity, possessing high thermal conductivity. Consequently, steel sheets are ineffective in preventing heat transfer and are not typically used as standalone insulation materials. Nonetheless, steel sheets can still offer some insulation benefits when utilized alongside other insulating materials. For example, they can serve as a protective layer or cladding, enhancing the durability and fire resistance of insulation systems. Additionally, they can function as a radiant barrier, redirecting heat away from buildings and reducing heat gain in warm climates. To summarize, although steel sheets themselves do not possess exceptional insulation properties, they can contribute to improving overall insulation performance when combined with other insulating materials or applied in specific scenarios such as radiant barriers.

- Q: How do steel sheets perform in terms of weathering?

- Steel sheets perform well in terms of weathering due to their inherent strength and durability. They are highly resistant to corrosion and can withstand harsh weather conditions such as rain, snow, and extreme temperatures. Additionally, steel sheets can be further protected through coatings and treatments, enhancing their ability to resist weathering and prolonging their lifespan.

- Q: What is the process of applying fire-resistant coatings to steel sheets?

- The process of applying fire-resistant coatings to steel sheets involves several steps. First, the surface of the steel sheets needs to be thoroughly cleaned to remove any dirt, grease, or contaminants. This can be done through abrasive blasting, solvent cleaning, or power washing. Once the surface is clean, a primer or base coat is applied to enhance adhesion and provide a smooth surface for the fire-resistant coating. The primer is typically applied using a brush, roller, or spray gun. After the primer has dried, the fire-resistant coating is applied. This coating is specifically designed to withstand high temperatures and provide protection against fire. It is usually applied in multiple layers for optimal effectiveness. The coating can be sprayed, rolled, or brushed onto the steel sheets. Once the fire-resistant coating is applied, it needs to cure or dry according to the manufacturer's instructions. This curing process ensures that the coating forms a strong bond with the steel surface and achieves its maximum fire-resistant properties. Overall, the process of applying fire-resistant coatings to steel sheets involves surface preparation, primer application, fire-resistant coating application, and curing. It is crucial to follow proper application techniques and adhere to manufacturer guidelines to ensure a durable and effective fire-resistant finish.

- Q: Are steel sheets resistant to water or moisture damage?

- Yes, steel sheets are generally resistant to water or moisture damage due to their non-porous nature. However, prolonged exposure to water or moisture can lead to corrosion over time if the steel is not properly protected or coated.

- Q: Can steel sheets be used for water treatment facilities?

- Yes, steel sheets can be used for water treatment facilities. Steel is a commonly used material in these facilities due to its durability, resistance to corrosion, and ability to withstand high pressure and temperature. Additionally, steel sheets can be easily fabricated and installed, making them suitable for various applications within water treatment facilities such as tanks, pipes, and equipment.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are designed to perform exceptionally well under heavy loads or pressure. Due to their high tensile strength and durability, steel sheets can withstand significant amounts of weight without bending or breaking. They offer excellent resistance to deformation and can maintain their structural integrity even when subjected to intense pressure. Hence, steel sheets are widely used in various industries for applications that require robust materials capable of bearing heavy loads or pressure.

- Q: Are steel sheets suitable for marine applications?

- Yes, steel sheets are suitable for marine applications. Steel is known for its high strength, durability, and corrosion resistance, making it an ideal material for various marine structures, such as ship hulls, offshore platforms, and marine equipment. Additionally, steel sheets can be easily fabricated and welded, providing versatility in design and construction.

Send your message to us

Steel Plate Lowest Price for Astm A36 carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords