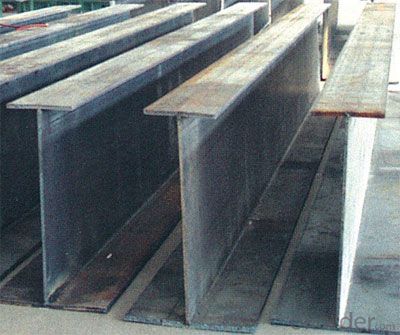

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

OKorder is offering Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

H beam is widely used in various building structure and engineering structure:

a).used for the plant, high-rise building construction

b).used for the bridge, shipment building

c).used for lifting and transportation machinery, equipment manufacturing base building

d).used for the support, foundation pile manufacturing

Main Product Features of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

1. Standard: JIS G3192 OR GB/T11263-2005

2. Grade: Q235/SS400/S235JR

3. Length: 6m-12m

4. Packing:standard export packagin

| STANDARD: JIS G3192 OR GB/T11263-2005 | |||

| H beam Section sizenma(mm) | Weight (kg/m) | ||

| Height×Breadth | Web thichness | Flange thichness | |

| 100×100 | 6 | 8 | 16.9 |

| 125×125 | 6.5 | 9 | 23.6 |

| 150×150 | 7 | 10 | 31.1 |

| 175×175 | 7.5 | 11 | 40.4 |

| 200×200 | 8 | 12 | 49.9 |

| 250×250 | 9 | 14 | 71.8 |

| 300×300 | 10 | 15 | 93.0 |

| 300×300 | 15 | 15 | 105.0 |

| 350×350 | 12 | 19 | 134.9 |

| 400×400 | 13 | 21 | 171.7 |

| 148×100 | 6 | 9 | 20.7 |

| 194×150 | 6 | 9 | 29.9 |

| 244×175 | 7 | 11 | 43.6 |

| 294×200 | 8 | 12 | 55.8 |

| 340×250 | 9 | 14 | 78.1 |

| 390×300 | 10 | 16 | 104.6 |

| 440×300 | 11 | 18 | 120.8 |

| 482×300 | 11 | 15 | 110.8 |

| 488×300 | 11 | 18 | 124.9 |

| 582×300 | 12 | 17 | 132.8 |

| 588×300 | 12 | 20 | 147.0 |

| 100×50 | 5 | 7 | 9.3 |

| 125×60 | 6 | 8 | 13.1 |

| 150×75 | 5 | 7 | 14.0 |

| 175×90 | 5 | 8 | 18.0 |

| 198×99 | 4.5 | 7 | 17.8 |

| 200×100 | 5.5 | 8 | 20.9 |

| 248×124 | 5 | 8 | 25.1 |

| 250×125 | 6 | 9 | 29.0 |

| 298×149 | 5.5 | 8 | 32.0 |

| 300×150 | 6.5 | 9 | 36.7 |

| 346×174 | 6 | 9 | 41.2 |

| 350×175 | 7 | 11 | 49.4 |

| 396×199 | 7 | 11 | 56.1 |

| 400×200 | 8 | 13 | 65.4 |

| 446×199 | 8 | 12 | 65.1 |

| 450×200 | 9 | 14 | 74.9 |

| 496×199 | 9 | 14 | 77.9 |

| 500×200 | 10 | 16 | 88.1 |

| 596×199 | 10 | 15 | 92.4 |

| 600×200 | 11 | 17 | 103.4 |

| 700×300 | 13 | 24 | 181.8 |

| 800×300 | 14 | 26 | 206.8 |

| 900×300 | 16 | 28 | 240.1 |

- Q: Are steel H-beams resistant to seismic activity?

- Yes, steel H-beams are generally considered to be resistant to seismic activity. Steel is a highly durable and strong material, which makes it well-suited for withstanding the forces generated during seismic events. H-beams, specifically, are designed to distribute the load evenly across their length, providing excellent structural support against both vertical and lateral movements. Moreover, steel H-beams are commonly used in earthquake-prone regions due to their superior seismic resistance. The inherent flexibility and elasticity of steel allow it to absorb and dissipate seismic energy, minimizing the damage caused by ground shaking. Additionally, steel H-beams are often interconnected with other structural elements, such as columns and braces, to form a seismic-resistant system that can effectively absorb and redirect seismic forces. However, it is important to note that the seismic resistance of steel H-beams can vary depending on various factors, such as the design, quality of construction, and adherence to building codes and regulations. Proper engineering and construction practices must be followed to ensure that steel H-beams are appropriately designed and installed to withstand the specific seismic conditions of a given area. Overall, when properly designed and constructed, steel H-beams offer excellent resistance to seismic activity and are widely used in earthquake-resistant building structures.

- Q: What are the factors that affect the cost of steel H-beams?

- There are several factors that affect the cost of steel H-beams. Firstly, the current demand and supply in the market play a significant role. If there is high demand and limited supply, the cost is likely to increase. Additionally, the cost of raw materials, such as iron ore and coal, which are used in the production of steel, can impact the price of H-beams. Other factors include manufacturing and transportation costs, tariffs and taxes, currency exchange rates, and any additional specifications or customization required by the customer.

- Q: Are steel H-beams suitable for long-span structures?

- Steel H-beams are indeed appropriate for long-span structures. Renowned for their high strength-to-weight ratio, they serve as an optimal option for such projects. Their ability to endure heavy loads and offer exceptional structural support across vast distances is well-known. The H-shaped design of these beams ensures superior weight distribution, thereby guaranteeing stability and minimizing deflection. Moreover, steel H-beams possess versatility, as they can be readily fabricated and tailored to meet precise project needs. Thanks to their reliability and efficiency, steel H-beams have established themselves as a dependable solution for a range of long-span structures, be it bridges, industrial buildings, or any other construction.

- Q: What are the considerations for designing with steel H-beams?

- When it comes to designing with steel H-beams, there are several important factors that must be kept in mind. Firstly, it is crucial to have a clear understanding of the load-bearing capacity of the H-beams. This involves determining the maximum weight that the beams can support and making sure that the design takes into account any potential dynamic or live loads that may be applied. The required strength of the beams can be calculated through structural analysis and design calculations, considering factors such as the span length, beam size, and material properties. Another factor to consider is the overall structural stability and rigidity of the H-beam design. While H-beams are known for their high strength-to-weight ratio, they can be vulnerable to lateral torsional buckling under certain conditions. Analyzing and designing for these potential stability issues is important to ensure the safety and integrity of the structure. This may involve adding additional bracing or stiffeners to the H-beams to enhance their stability. Proper connection detailing is also a crucial aspect of designing with steel H-beams. The connections between the H-beams and other structural members, such as columns or beams, need to be carefully designed to ensure that loads are transferred correctly and that there is structural continuity. The type of connection, whether it is bolted, welded, or a combination of both, should be chosen based on factors such as expected loads, construction constraints, and desired structural flexibility. Fire resistance is another consideration when working with steel H-beams. While steel is inherently fire-resistant, it can lose its strength and stiffness when exposed to high temperatures for extended periods. Therefore, it is important to think about fire protection measures, such as fireproof coatings or the use of fire-resistant materials, to ensure that the H-beams maintain their structural integrity in the event of a fire. Lastly, the cost and availability of steel H-beams should be taken into account during the design process. The size, grade, and quantity of H-beams needed for the project can impact the overall cost and feasibility of the design. It is also important to consider the availability of the required H-beams in the market to avoid potential delays or cost overruns. In conclusion, designing with steel H-beams requires careful consideration of load-bearing capacity, structural stability, connection detailing, fire resistance, and cost factors. By addressing these factors, a well-designed H-beam structure can be achieved that meets the necessary performance criteria and ensures the safety and durability of the project.

- Q: Can steel H-beams be used in residential construction?

- Yes, steel H-beams can be used in residential construction. H-beams, also known as I-beams, are commonly used structural components in construction projects, including residential buildings. They are designed to provide strength and support, making them suitable for various applications such as load-bearing walls, floor joists, and roof supports. Steel H-beams offer several advantages in residential construction, including high strength-to-weight ratio, durability, and resistance to fire, pests, and rot. Additionally, their uniform shape and size allow for easy installation and integration into the overall structural system. Overall, steel H-beams are a popular choice in residential construction due to their versatility and reliability.

- Q: How do you calculate the moment of resistance for steel H-beams?

- One can calculate the moment of resistance for steel H-beams by utilizing the given formula: M = fy * Z. In this equation, M represents the moment of resistance, fy denotes the yield strength of the steel, and Z signifies the plastic section modulus of the H-beam. To ascertain the plastic section modulus, it is necessary to ascertain the extreme fiber distances from the neutral axis of the H-beam. These measurements can be obtained either from the manufacturer's specifications or by measuring the beam's dimensions. Once the extreme fiber distances have been determined, the plastic section modulus can be calculated using the subsequent formula: Z = (b1 * h1^2 / 6) + (b2 * h2^2 / 6) + (b3 * h3^2 / 6). In this equation, b1, b2, and b3 represent the widths of the various sections of the H-beam, while h1, h2, and h3 correspond to the heights of the different sections. After calculating the plastic section modulus, it can subsequently be multiplied by the yield strength of the steel to establish the moment of resistance. It is imperative to note that this calculation assumes that the steel H-beam behaves in an elastic-perfectly plastic manner and that the material does not exceed its yield strength.

- Q: Are steel H-beams resistant to termites or pests?

- Yes, steel H-beams are resistant to termites and pests.

- Q: Can steel H-beams be used in historical or heritage building restoration?

- Yes, steel H-beams can be used in historical or heritage building restoration. In fact, steel H-beams are often preferred in restoration projects due to their strength, durability, and versatility. These beams can provide structural support to weakened or damaged areas of a building, helping to ensure its stability and longevity. Additionally, steel H-beams can be customized and fabricated to match the original architectural features of the building, allowing for a seamless integration with the existing structure. Despite being a modern material, steel H-beams can be designed to mimic traditional construction methods, preserving the historical integrity of the building while providing the necessary reinforcement. Therefore, steel H-beams are a viable option for restoring historical or heritage buildings.

- Q: How do steel H-beams contribute to sustainable building certifications?

- Steel H-beams contribute to sustainable building certifications in several ways. First, they are made from recycled materials, reducing the demand for new resources and minimizing the environmental impact of the construction process. Additionally, steel H-beams are highly durable and have a long lifespan, reducing the need for frequent replacements and conserving materials over time. Their structural efficiency also allows for lighter building designs, reducing overall energy consumption and minimizing carbon emissions. Moreover, steel H-beams are often fabricated off-site, reducing construction waste and improving the efficiency of the building process. Overall, the use of steel H-beams in construction can help achieve sustainable building certifications by promoting resource efficiency, durability, and reduced environmental impact.

- Q: Can steel H-beams be used in commercial building facades?

- Yes, steel H-beams can be used in commercial building facades. Steel H-beams are strong and durable structural components that are commonly used in both industrial and commercial construction projects. They provide excellent load-bearing capabilities and can withstand heavy loads and forces, making them suitable for supporting the weight of a building's façade. Additionally, steel H-beams offer design flexibility as they can be fabricated in various sizes and shapes to meet the specific requirements and architectural aesthetics of a commercial building. They are also resistant to weathering, corrosion, and fire, which makes them a reliable choice for commercial building facades. Overall, steel H-beams are a popular and widely-used material in the construction industry and can be effectively utilized in commercial building facades.

Send your message to us

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords