Steel Formwork for Living Room with reliable quality and long using time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

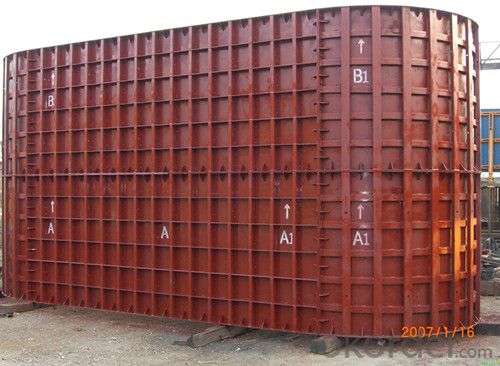

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

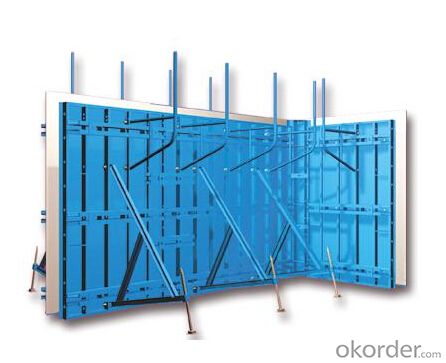

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: Can steel formwork be used for both straight and curved structures?

- Yes, steel formwork can be used for both straight and curved structures. Steel formwork is versatile and can be easily shaped and adjusted to create various geometric shapes, including straight walls and columns as well as curved structures such as arches and curved walls. This flexibility allows for the creation of unique architectural designs and structures. Additionally, steel formwork has high strength and durability, making it suitable for use in both straight and curved structures.

- Q: What are the typical safety precautions when working with steel formwork?

- When working with steel formwork, some typical safety precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. Additionally, workers should receive proper training on the proper handling and installation techniques of steel formwork systems. It is essential to ensure that the formwork is securely supported and adequately braced to prevent collapse or accidents. Regular inspection of the formwork for any damages or defects is also crucial to maintain a safe working environment.

- Q: Are all steel plates used for beam slab prefabrication

- Should be determined according to the shape of the prefabricated components, specifications, to facilitate construction, cost savings, to ensure the quality of the premise.

- Q: What are the considerations when designing steel formwork for high-rise buildings?

- When designing steel formwork for high-rise buildings, it is important to consider several key factors: 1. Load-bearing capacity: High-rise buildings experience significant vertical and lateral loads. Therefore, the steel formwork must be able to support the weight of the concrete and any additional loads, such as equipment or workers. 2. Structural stability: The design of the steel formwork should ensure structural stability during the construction process. This involves considering factors like building height, wind loads, and the possibility of earthquakes. Proper bracing and reinforcement are necessary to maintain formwork stability. 3. Durability: High-rise buildings often have longer construction periods, so the formwork must be able to withstand prolonged exposure to concrete, weather conditions, and repetitive use. To enhance durability, the steel formwork should be designed with corrosion-resistant materials and protective coatings. 4. Flexibility and adaptability: High-rise buildings often have complex architectural designs and irregular shapes. Therefore, the formwork system should be flexible and adaptable to accommodate variations in geometry. This allows for efficient construction and minimizes the need for custom-made components. 5. Safety: Safety is of utmost importance when designing steel formwork for high-rise buildings. The formwork should be designed to prevent accidents and ensure the well-being of workers. Safety features such as guardrails, toe boards, and safe access points should be incorporated. 6. Ease of assembly and disassembly: Assembling and disassembling formwork for high-rise buildings can be labor-intensive and time-consuming. To streamline the construction process, the formwork system should have easy-to-use connections, standardized components, and clear assembly instructions. 7. Cost-effectiveness: High-rise construction projects often have limited budgets. Therefore, the design of the steel formwork should take into account its cost-effectiveness. This includes considering the potential for formwork reuse, minimizing the need for additional support structures, and optimizing the use of materials. By carefully considering these factors, designers can ensure that the steel formwork for high-rise buildings is strong, safe, durable, and cost-effective, enabling the successful construction of these complex structures.

- Q: How does steel formwork affect the overall energy efficiency of the structure?

- Steel formwork can positively impact the overall energy efficiency of a structure in several ways. Firstly, steel formwork provides a durable and robust framework, ensuring precise construction and reducing the need for additional materials. This results in a more tightly sealed structure, minimizing air infiltration and heat loss. Additionally, steel formwork allows for the efficient installation of insulation materials, improving thermal performance and reducing energy consumption for heating and cooling. Moreover, the reusable nature of steel formwork reduces waste and promotes sustainability, which further enhances the overall energy efficiency of the structure.

- Q: What is the expected lifespan of steel formwork ties?

- Several factors, including the quality of the steel, usage conditions, and maintenance, can influence the lifespan of steel formwork ties. Generally, these ties are designed to have a long lifespan and can be reused multiple times. When high-quality steel formwork ties are used in appropriate conditions and properly maintained, they can endure for several years. By regularly cleaning, inspecting, and maintaining them, they can be reused for multiple construction projects, thereby reducing costs and waste. It is essential to note that steel formwork ties may deteriorate over time, especially when exposed to harsh environmental conditions or corrosive substances. Therefore, it is crucial to regularly inspect the ties for any signs of damage or corrosion and replace them if necessary. Additionally, proper storage and handling of the ties when not in use can also contribute to extending their lifespan. In conclusion, the lifespan of steel formwork ties is not fixed, but with proper maintenance and care, they can last for several years and be reused multiple times. This makes them a cost-effective and sustainable choice for construction projects.

- Q: What are the advantages of using modular steel formwork systems?

- Using modular steel formwork systems in construction projects offers several advantages. Firstly, these systems provide a high level of accuracy and precision. Designed with pre-fabricated panels and components that seamlessly fit together, they ensure precise alignment and consistent results. This accuracy leads to a high-quality finish and reduces the need for rework or corrections. Secondly, modular steel formwork systems are highly versatile and adaptable. They can be easily adjusted and customized to meet the specific requirements of different projects, including various shapes, sizes, and configurations. This flexibility allows for efficient construction of complex structures and optimizes the use of materials. Additionally, modular steel formwork systems are incredibly durable and long-lasting. Steel is a strong and robust material that can withstand heavy loads and extreme weather conditions, making it ideal for construction purposes. This durability ensures that the formwork system can be used repeatedly, reducing the need for frequent replacements and saving costs in the long run. Moreover, modular steel formwork systems offer significant time savings during the construction process. They can be quickly assembled and dismantled, allowing for faster construction cycles and improved project timelines. The ease of use and efficient installation of these systems help in reducing labor requirements and increasing productivity on-site. Lastly, modular steel formwork systems promote sustainability in construction. Steel is a recyclable material, and using modular systems reduces the amount of waste generated during the construction process. Additionally, the reusability of the formwork system reduces the consumption of timber, which is often used in traditional formwork methods. In conclusion, the advantages of using modular steel formwork systems include high accuracy, versatility, durability, time savings, and sustainability. These systems provide construction projects with efficient and cost-effective solutions, ensuring high-quality results and long-term benefits.

- Q: Can steel formwork be used for both vertical and horizontal structures?

- Yes, steel formwork can be used for both vertical and horizontal structures. Steel formwork is a versatile and durable construction material that can be molded and shaped to meet the requirements of various structural elements. It can be used for constructing walls, columns, beams, slabs, and other structural elements in both vertical and horizontal orientations. The strength and rigidity of steel make it suitable for withstanding the pressure exerted by concrete during the casting process, ensuring that the formwork maintains its shape and stability. Additionally, steel formwork is reusable and can be easily dismantled and reassembled, making it a cost-effective and efficient choice for construction projects involving both vertical and horizontal structures.

- Q: How does steel formwork affect the overall carbon footprint of the project?

- Steel formwork can significantly reduce the overall carbon footprint of a project due to its durability and reusability. As compared to traditional timber formwork, steel formwork can be used multiple times, thereby reducing the need for frequent replacements and lowering the amount of waste generated. Additionally, steel production emits less carbon dioxide than timber production, making steel formwork a more sustainable choice.

- Q: What are the common challenges faced during steel formwork removal?

- One of the common challenges faced during steel formwork removal is the difficulty in disassembling the formwork due to the tight connections and fasteners used in its construction. Steel formwork is designed to provide a rigid structure, and as a result, it can be challenging to remove without the proper tools and techniques. Another challenge is the weight of the steel formwork. Steel is a heavy material, and when used in formwork, it can make the removal process physically demanding. Proper lifting equipment and techniques are required to safely remove the formwork without causing any injuries to the workers. Corrosion can also be a challenge during steel formwork removal. Over time, steel formwork can be exposed to moisture, which can lead to rust and corrosion. This can make the formwork more difficult to dismantle, as the rusted parts may be stuck together or weakened. Proper maintenance and regular inspections can help prevent or identify corrosion early on, reducing the challenges during removal. Additionally, the presence of concrete residue can pose challenges during steel formwork removal. Concrete can adhere to the formwork, making it difficult to separate the two. This can be time-consuming and may require additional tools or methods, such as chipping or using release agents, to facilitate the removal process. Lastly, the coordination and timing of the formwork removal can be a challenge. Removing the formwork too early can result in structural instability, while removing it too late can cause delays in subsequent construction activities. Proper planning and communication between the construction team are crucial to ensure the formwork removal is done at the right time and in the correct sequence. In conclusion, the common challenges faced during steel formwork removal include tight connections and fasteners, the weight of the formwork, corrosion, concrete residue, and coordination and timing. Overcoming these challenges requires proper tools, techniques, maintenance, and effective communication among the construction team.

Send your message to us

Steel Formwork for Living Room with reliable quality and long using time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches