Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Steel Cuplock Scaffolding System for Concrete Building Construction

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

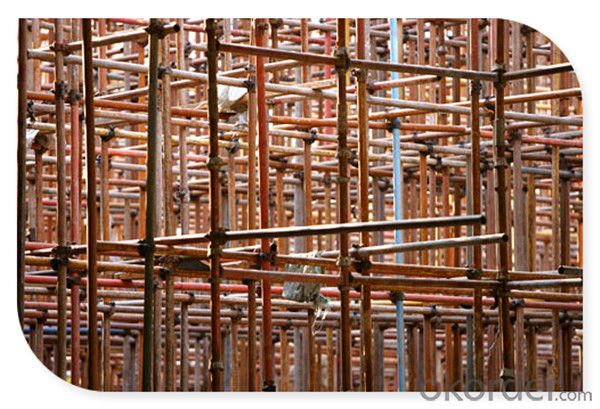

Descriptions of Steel Cuplock Scaffolding System for Concrete Building Construction

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System for Concrete Building Construction

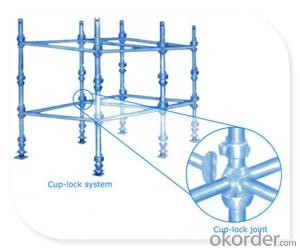

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Steel Cuplock Scaffolding System for Concrete Building Construction

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- Cross barName specification A (mm) B (mm) theoretical weight (kg)

- Q: What's an antonym for the word scaffold?

- Since a scaffold is a bridge/ladder/support used to allow you to span the gap between you and and object you wish to reach, I'd go with barrier.

- Q: The role of the external scaffolding and the relevant provisions?

- These two functions are often concurrent. With the protection of the role of security, in order to play the role of height operation; can not guarantee the safety of the role, the construction personnel can not operate on the above. These two functions, the protection of human safety is the first. Construction workers in the scaffolding on the construction work, there is a sense of security, construction progress, the quality of the project is sufficient protection, in order to create good economic benefits. Otherwise, once the danger of scaffolding, will cause many casualties, causing significant losses. Therefore, in the development of scaffolding support programs and scaffolding erection, we must firmly grasp the quality.

- Q: hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- carefully clean the fresh blood off then leave it alone after that - dont keep removing the dry blood - then clean it with saline solution/salt water and antibacterial stuff

- Q: What are the dangers of scaffolding

- The scaffold and bar for use of instability, binding is not strong or break and fall; the improper operation of the impact and accident etc.;Improper operation generally have the following situations:A. overexert, causing physical instability;B. in the frame and pull the car back walking;C. crowded collision;D. many people handling or installation of heavier components;Ice and snow on the E. frame is not clear, causing the slide.

- Q: Do the external wall decoration (from the top down to do) scaffolding is to wait until after the completion of the indoor and outdoor decoration before the demolition?If the first interior decoration, can make a layer of a layer of it is to remove all the work finished I mean I finished all the interior decoration, wall decoration only, then I do a wall decoration on the demolition of a layer of scaffolding, this site useful no

- Two, removal of scaffolding, should meet the following requirements:1, the demolition work must be from top to bottom layer by layer, prohibited from top to bottom operation at the same time;2, even the wall must be removed with the scaffolding layer by layer, is strictly prohibited even after the first wall or a few layers of the demolition of the demolition of the scaffolding; demolition of the height difference should not be greater than 2 steps, such as the height difference is greater than the step, should be added to strengthen the wall;3, when the scaffolding down to the bottom of a long rod height (about 6.5m), should be in the appropriate position to set up temporary support reinforcement, and then dismantle the wall;4, when the scaffolding to take the sub section, the demolition of the sub elevation, the demolition of the scaffold should not be removed at both ends, should be added to the wall and lateral oblique reinforcement.

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: Scaffolding scaffolding erection norms which requirements, who can say?

- The construction load on the frame must be in accordance with the design requirementsAfter the first erection of the body, must be approved by the company's safety and technical departments, and the company's project safety officer after the visa can continueIn case of suspension frame, use more than one month, such as re started, the frame must pass the reinforcement, rod must be re tighten oil, can be usedBefore the building should be approved with the consent of the special construction plan, should be in accordance with the scheme requirements of embedded embedded parts of the main structure of the construction processFeet should be laid flat tile, and tied with wire fixed on the lower supporting steel pipe. Scaffold of the butt joint between the tile, the rest of the bearing rail spacing shall not be greater than 400~700 mm

- Q: Where can I source scaffolding steel/aluminium planks with rubber end caps?I am having much difficultly finding anything, can you assist?Thank you in advance.

- Maybe something like a window washers scafolding planks...?

- Q: Im a wimp for pain and im looking to get my scaffolding done. i want to know how painful it isI already have both lobs pierced and stretched to an 8mm, will the pain be similar to that?

- Depends on your pain tolerance, it's different for everyone. But generally cartilage piercings feel nothing like getting piercings stretched.

Send your message to us

Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords