Steel Cuplock Scaffolding System Factory Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Steel Cuplock Scaffolding System Factory Supply

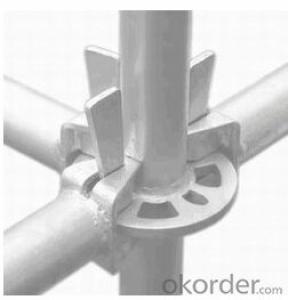

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

Descriptions of Steel Cuplock Scaffolding System Factory Supply

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System Factory Supply

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Steel Cuplock Scaffolding System Factory Supply

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Room 29 meters outside the wall of the two rows of steel pipe scaffolding installation, demolition, joint protection measures in Wuhan, the price per square is how much money? A friend to help refer to Kazakhstan

- With regard to the design and construction of floor type (double pole type) single and double row steel pipe scaffold for industrial and civil construction, and the design and construction of formwork support in the construction of horizontal concrete structure. National compulsory technical norms, because of its complexity, and you proposed "one square meter standard steel scaffolding the number of meters" is a vague and unclear description of the problem, considering the matter of security,

- Q: Should the WWE put John Cena in a triple threat thumbtack scaffold cage of death with New Jack & Necro Butcher?

- They should do that to you, hypocritical bastard . Get a life . Edit: It isn't hypocritical to hate John Cena, it's hypocritical to want to put him in that type of situation . He could most definitely die from that .

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: I couldn't believe it, but yes it happened...

- yea I can believe that. There have been people who have survived jumping out of planes at ten thousand feet. One guy landed in a snow bank and I think another hit a tree and I guess it was some kind of pine and the branches slowed him down.

- Q: opinions on scaffolding piercing and how to hide it from school :)?

- Why do you have to hide it? It's an ear piercing. And to hide it, just cover it with your hair.

- Q: Construction scaffolding right angle fastener, rotary fastener, butt fastener weight? There are more than one meter steel pipe?Thank you!!!

- Weight: 48kg above 3, single piece weight in 20Kg or so, easy to carry and construction operation. 4, the installation and removal of only bare handed, greatly improved the efficiency of the door scaffolding installed than the fastener steel tube fast 1/2 time, faster than bamboo scaffolding 2/3 time. 2 the maximum weight of a single piece is not more than 20 kg, so lifting, assembling and disassembling and transportation are convenient

- Q: also apprx. what chapters is it in?

- The Democrats took decrease back a majority particularly through attacking Republicans on the unpopularity of the conflict and Bush's adverse approval rankings. there have been additionally various ethics scandals concerning republicans that twelve months that led to various of them resigning their seats and a regular loss of self belief that strengthened Democrat momentum. Tom postpone resigned after being charged with marketing campaign finance violations. He substitute into never convicted. Mark Foley sexually under pressure an underage male congressional website. The Abramoff indictment solid suspicion on all and sundry in Washington, extraordinarily those in ability. Scooter Libby substitute into Indicted. It substitute into basically a nasty twelve months to be a republican. a brilliant number of the scandals disappeared after the elections and became out to be not something. some indictments caught, and extremely, in basic terms as many democrats have been grimy as republicans. yet comparable to a corrupt regime helped positioned the democrats on top of issues. Then all their can provide to question Bush and end the conflict dwindled into not something as they took over the political equipment and grew to alter into as corrupt as a results of fact those they replaced.

- Q: What are the common rules for calculating the amount of scaffolding works

- General rules for the calculation of scaffolding:Masonry works (including building blocks) are higher than 1m when calculated by external scaffolding. Independent column height of less than 3.6m according to the core of the core of the circumference of the height of the calculation of the height of the project; the height of more than 3.6m of the column core circumference plus 3.6m multiplied by the actual height of the project to calculate the amount of masonry.

- Q: How to remove the disc scaffolding ah, do not know how to get through the decoration

- Second, the demolition of disc type scaffolding parts down to classify storage and management, in order to transport, but also a process of removing parts check the parts, to separate the deformation, the rusty parts, don't put the next time in construction.

- Q: The basic form of external scaffolding

- Basic structureA bowl type steel tube scaffold is a multifunctional scaffold in our country with reference to foreign experience developed, its member nodes connected with bowl, because the bowl is fixed on the steel pipe, all components of the axial connection, good mechanical properties, which is reliable, consisting of the scaffold with good integrity, there is no fastener lost problem.

Send your message to us

Steel Cuplock Scaffolding System Factory Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords