Steel Coil or Sheet Cold Rolled of JIS G3141-1996, EN 10131-2006, DIN EN 1002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Refrigerators, cabinets, power distribution baords and drums.

Automobile floor and roof panels.

Description

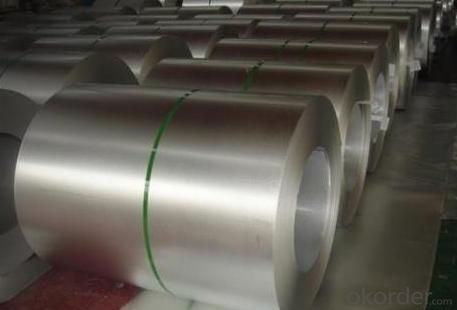

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Thickness: 0.16mm-1.0mm

3) Width:30mm-1250mm

4) Length: As requested

5) Width tolerance: different as per different width

6) Thickness tolerance: different as per different thickness

7) Weight: According to the different requirement

8) Packing: Mill standard export packing in bundles

9) Country of Origin : China

10)Standard: AISI, ASTM29, DIN16723, EN10130, JIS, GB

11)Grade: SPCC, SPCD, SPCE, SPCH, ST12-15, DC01-06, Q195A-Q235A

12)Width: 30-1250mm (general width: 100mm, 610mm, 1200mm)

Application:

1.For the further producing of hot dip galvanized steel products

2.Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

Others

1.Packing: Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from

2. Payment term: L/C, T/T

3. Delivery date: 15-30 days

- Q: I'm looking for a good source as to the 'structural formula' of steel. I'm not quite sure if that's what it's actually called, but here's a link to what I'm looking for.

- structural formula only apply to a chemical compound, and steel is not that. It is a MIXTURE, an alloy, of iron, carbon, and any of a number of other materials, such as chromium, manganese, etc.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed and formed into various shapes such as beams, columns, and plates. These coils are first uncoiled and then cut into desired lengths before being shaped and welded together to create strong and durable structural components used in buildings, bridges, and other infrastructure projects.

- Q: it has 2 be 20 inches overall, and 2and1/2 inches wide and .25 or more inches thick... im thinking truck steel but im not sure thx

- Well okorder /

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- A nylon string guitar, more properly called a classical guitar, is used almost exclusively for playing classical music. Unless you're interested in classical music you should avoid this guitar. Also, it is only played fingerstyle so you will not be able to learn how to use a pick, which is a valuable, necessary skill. Steel string acoustic guitars are used for a wide variety of music including rock, pop, folk, bluegrass, and more. This is a much more versatile guitar and is the one you probably should have bought.

- Q: is a 1962 steel penny worth anything?

- Is this an american penny? If it is, it is copper. They only made steel pennies in 1943. Someone claims they have seen a rare 1944, but who really knows? A 1962 will be worth a penny unless it is part of a mint or proof set. During WW II, all 1943 U.S. cents were struck in zinc-finished steel instead of copper. The copper saved from this one-year issue was used in the war effort, mainly in the manufacture of shell casings. Most of the so calledsteelies were minted in Philadelphia, but some steel pennies were struck in Denver, and San Francisco. Edit Brandi: If it is steel it will stick to a magnet. It truly sounds like you have a discolored penny. This can happen with exposure to different chemicals and even machine washing. The D means that it was minted in Denver You can view a lot of different coin collection samples on OKorder. The values are consistent with expert numismatic pricing. I strongly feel you have a 1962 copper penny.

- Q: How are steel coils used in the manufacturing of cables?

- Steel coils are commonly used in the manufacturing of cables to provide strength and support. The steel coils are typically wrapped around the cable core to enhance its structural integrity, increase tensile strength, and protect against external forces. This reinforcement allows the cables to withstand tension and bending, ensuring their durability and reliability in various applications such as power transmission, telecommunications, and construction.

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: How do steel coils contribute to the water and wastewater industry?

- The water and wastewater industry heavily relies on steel coils as a crucial component for constructing and maintaining its infrastructure. These coils, made from high-quality steel, offer numerous advantages for the industry. To begin with, steel coils are essential in the production of pipes and tubes used primarily for transporting water and wastewater. Steel pipes are renowned for their exceptional strength and durability, enabling them to withstand high pressure and heavy loads. This makes them ideal for water distribution systems, sewage networks, and treatment plants. Steel coils provide the necessary material to manufacture these pipes, ensuring reliable and long-lasting infrastructure. Furthermore, steel coils are also utilized in constructing storage tanks and reservoirs. These tanks are vital for water treatment plants, serving as storage for large volumes of water or wastewater during the treatment process. Steel coils provide the required material for fabricating these tanks, guaranteeing their structural integrity and preventing leaks or contamination. Moreover, steel coils are used in manufacturing various equipment and components indispensable in the water and wastewater industry. For instance, steel coils are employed to produce pumps, valves, and control systems, which are crucial for the efficient operation of water treatment plants, pumping stations, and sewage networks. Steel's strength and corrosion resistance make it an ideal material for these applications, ensuring reliable and long-lasting equipment. Additionally, steel coils are also employed in constructing wastewater treatment plants and facilities. These plants employ various processes to eliminate contaminants from wastewater before discharging it into the environment. Steel coils provide the necessary material for constructing these facilities, including structural supports, tanks, and other components. The durability and resilience of steel ensure the longevity and efficiency of these treatment plants. In conclusion, steel coils play an integral role in the water and wastewater industry by contributing to the construction and maintenance of critical infrastructure. They are used in manufacturing pipes, tanks, equipment, and facilities, guaranteeing the strength, reliability, and durability required for the efficient operation of water and wastewater systems.

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers typically handle international shipping requirements by following a well-defined process. First, they ensure proper packaging and securing of the coils to prevent damage during transportation. This may involve using specialized equipment, such as coil racks or crates. Next, they comply with international shipping regulations and obtain necessary documentation, such as bills of lading and customs clearance forms. They coordinate with freight forwarders or shipping agents to arrange transportation and select the most suitable shipping method, whether it's by sea, air, or land. Throughout the process, manufacturers closely track shipments and communicate with customers to ensure smooth delivery and address any issues that may arise.

- Q: Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- There is a chemical that is used presently that is sprayed onto steel beams called Monocoat. Its a form of insulation that gives steel protection for up to 2 hours I think. Hope that helps!

Send your message to us

Steel Coil or Sheet Cold Rolled of JIS G3141-1996, EN 10131-2006, DIN EN 1002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords