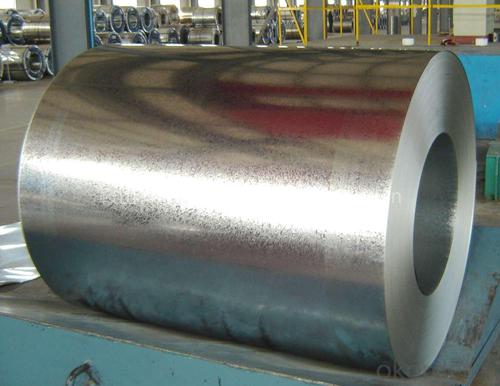

Steel Coil Galvanized Zinc Coating Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Coil Galvanized Zinc Coating Surface

Main Structure of Steel Coil Galvanized :

1.Thickness:0.14-2.5mm

2.Width:600-1250mm

3.Grade:SGCC,JISG3302,DX51D,Q235

4.Zinc Coating:60-275g/m2

5.Coil ID:508mm/610mm

6.Coil weight:3-8ton

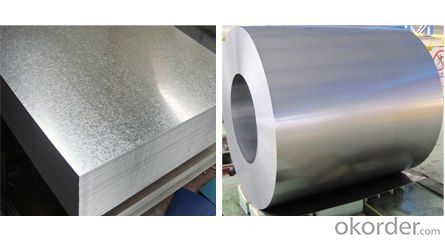

Specification of Steel Coil Galvanized:

| Commodity | Steel coil galvanized Zinc coating |

Tech Standard | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-2.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20'containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| Payment terms | T/T OR L/C |

| delivery time | 25 days after recepit of deposit |

FAQ

Q: Why should you choose us:

A: 1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Pictures

- Q: How do steel coils contribute to the strength and durability of structures?

- Steel coils contribute to the strength and durability of structures by providing a high tensile strength and resistance to deformation. The coils are typically made from high-quality steel, which has excellent structural properties. When used in construction, steel coils can be shaped and formed into various structural components, such as beams, columns, and trusses. These components add strength and stability to the structure, making it more resistant to external forces, such as wind, earthquakes, and heavy loads. Additionally, steel coils are highly durable and can withstand harsh environmental conditions, including corrosion and extreme temperatures, ensuring the long-term integrity of the structure.

- Q: How are steel coils used in the manufacturing of industrial boilers?

- Steel coils are used in the manufacturing of industrial boilers as they are shaped and welded to form the boiler shell. The coils provide the necessary strength and durability to withstand high pressure and temperature conditions in the boiler. Additionally, the coils are often used to create the tubes and pipes that circulate the hot gases and water within the boiler, facilitating efficient heat transfer and steam generation.

- Q: How do steel coils contribute to the HVACR equipment industry?

- Steel coils are an essential component in the HVACR equipment industry as they are used in various applications such as heat exchangers, condenser coils, and evaporator coils. These coils provide a durable and efficient solution for transferring heat, ensuring optimal performance and energy efficiency of HVACR systems. Additionally, steel coils offer excellent corrosion resistance, allowing them to withstand harsh environmental conditions and extend the lifespan of the equipment. Overall, steel coils play a crucial role in enhancing the functionality and longevity of HVACR equipment.

- Q: What are the properties of high-strength steel coils?

- High-strength steel coils possess a range of unique characteristics that make them highly sought-after in diverse industrial applications. Firstly, these coils demonstrate extraordinary strength, enabling them to withstand substantial force or weight without deformation or breakage. This quality renders them suitable for demanding environments and heavy-duty purposes. Another noteworthy property of high-strength steel coils is their exceptional resistance to wear and tear. They exhibit a high level of hardness, allowing them to endure abrasion, impact, and other forms of mechanical stress. Consequently, they prove ideal for applications where durability and longevity are paramount, such as construction, automotive manufacturing, and machinery production. Furthermore, high-strength steel coils frequently exhibit remarkable corrosion resistance. They are typically coated or treated with protective materials to prevent rust or other types of deterioration caused by exposure to moisture, chemicals, or harsh environmental conditions. This corrosion resistance ensures the durability and reliability of the coils, making them well-suited for use in marine environments or outdoor structures. Additionally, high-strength steel coils offer excellent formability, meaning they can be easily shaped or bent without compromising their strength or integrity. This characteristic empowers manufacturers to create intricate or customized shapes for specific applications, enhancing the versatility and adaptability of the coils. Lastly, high-strength steel coils are renowned for their lightweight nature compared to other materials possessing similar strength properties. This low weight-to-strength ratio positions them as the preferred choice in industries that prioritize weight reduction, such as aerospace or automotive manufacturing. It facilitates improved fuel efficiency, increased payload capacity, and overall cost savings. In conclusion, high-strength steel coils possess exceptional strength, resistance to wear and tear, corrosion resistance, formability, and lightweight characteristics, rendering them invaluable and versatile materials in a wide array of industries.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: How are steel coils inspected for defects?

- To ensure the quality of steel coils meets required standards, various methods are used to inspect them for defects. Visual inspection is a common method, where trained inspectors examine the coil's surface for visible defects like cracks, scratches, or dents. This can be done through direct observation or with the help of magnifying tools. Another method is magnetic particle inspection, which detects surface and near-surface defects like cracks or voids. Here, a magnetic field is applied to the coil, and magnetic powder is spread on the surface. If any defects are present, the powder will be drawn to them, making them visible to the inspector. Ultrasonic testing is also commonly employed to inspect steel coils for defects. It involves transmitting high-frequency sound waves into the coil and analyzing the reflected waves. Any deviations in the sound waves can indicate the presence of defects like cracks or voids within the coil. Eddy current testing is another method used to detect defects in steel coils. It works by using electromagnetic induction to generate eddy currents within the coil. Any changes in these currents caused by defects in the material are detected and analyzed by the inspector. Finally, in some cases, destructive testing is performed on steel coils. This involves taking a sample from the coil and subjecting it to tests such as tension or bend testing. These tests evaluate the mechanical properties of the steel and indirectly indicate the presence of defects. Overall, a combination of visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and potentially destructive testing is used to inspect steel coils for defects. These methods ensure that any defects are identified and addressed, guaranteeing the delivery of high-quality steel coils to customers.

- Q: How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they are cut and shaped into various components, such as frame rails and crossmembers, which form the structural foundation of the vehicle. The high strength and durability of steel make it an ideal material for chassis construction, providing stability and safety to the overall vehicle structure.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- if you can get a good picture of the bridge i can tell for sure i thing steel

- Q: How are steel coils used in the production of metal roofing panels?

- Steel coils are a critical component in the production of metal roofing panels. These coils, which are rolled sheets of steel, play a crucial role in shaping and forming the panels. To start with, the steel coils are unwound and fed into a machine called a roll former. This machine uses a series of rollers and dies to gradually shape and bend the steel into the desired profile of the metal roofing panel. The coils pass through these rollers, which apply pressure and force to mold the steel into the required shape and size. Once the metal has been formed into panels, it may undergo additional processes to enhance its durability and appearance. This can include galvanizing or coating the panels with various protective layers to prevent corrosion and improve weather resistance. These additional steps help to ensure that the metal roofing panels are able to withstand harsh environmental conditions and provide long-lasting performance. Steel coils are preferred in the production of metal roofing panels due to their strength and durability. Steel is known for its exceptional strength-to-weight ratio, making it a suitable material for roofing applications. Additionally, steel is highly resistant to various weather conditions, including high winds, heavy rains, and extreme temperatures. This makes it an ideal choice for roofing panels that need to withstand the elements and provide reliable protection for buildings. Overall, steel coils are an essential component in the manufacturing process of metal roofing panels. They are used to shape and form the panels, which are then further processed to enhance their durability. The use of steel in these panels ensures that they can withstand harsh weather conditions and provide long-lasting performance for residential, commercial, and industrial buildings.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

Send your message to us

Steel Coil Galvanized Zinc Coating Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords