Stainless Steel Sheet/Plate 304 with Low Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 304 with Low Pricing

Description of Stainless Steel Sheet/Plate 304 with Low Pricing:

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Main Features of Stainless Steel Sheet/Plate 304 with Low Pricing:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 304 with Low Pricing:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 304 with Low Pricing:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

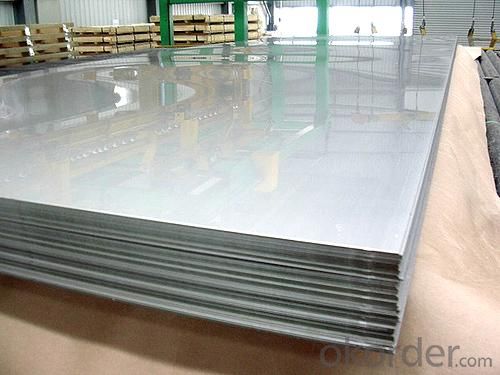

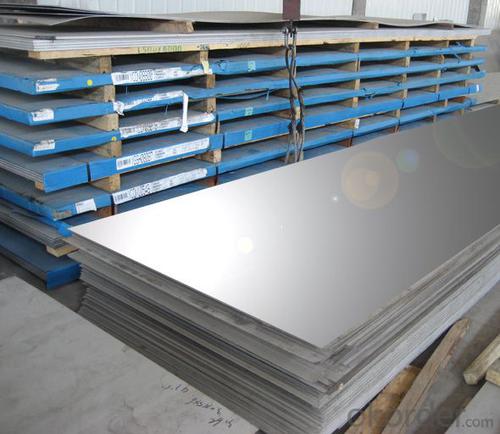

Images of Stainless Steel Sheet/Plate 304 with Low Pricing:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 304 with Low Pricing:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the different welding techniques used for stainless steel sheets?

- Various welding techniques are commonly employed for stainless steel sheets, each offering distinct advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding, a versatile and precise method, proves suitable for thin stainless steel sheets. It involves using a non-consumable tungsten electrode to generate an electric arc that melts and fuses the metals. High-quality welds with minimal heat distortion and excellent aesthetic appearance are ensured. 2. MIG Welding (Gas Metal Arc Welding): MIG welding, known for its efficiency and user-friendliness, is a popular choice for stainless steel sheets. It employs a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding exhibits faster speed than TIG welding and performs well on thicker stainless steel sheets. 3. Spot Welding: Joining two stainless steel sheets together, spot welding applies pressure and heat using electrodes. This technique finds common use in applications where a continuous seam is unnecessary, such as in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Similar to TIG welding, plasma arc welding employs a more concentrated arc produced by a constricted nozzle. This technique allows for deeper penetration on stainless steel sheets, making it suitable for thicker materials or specialized applications. 5. Laser Welding: Laser welding, a precise and rapid technique, employs a high-powered laser beam to melt and join stainless steel sheets. It offers exceptional control over the welding process and proves suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. The choice of welding technique depends on various factors, including the thickness of the stainless steel sheets, desired weld quality, production speed, and equipment availability. Each technique possesses its own advantages and limitations.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets are utilized in numerous industries and applications due to their wide range of standard sizes and thicknesses. Typically, the standard sizes vary from 4 feet by 8 feet to 5 feet by 10 feet, but customized sizes can also be obtained based on specific needs. In terms of thickness, stainless steel sheets are offered in various standard options. These include 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). It is important to note that these thicknesses indicate the nominal thickness, and the actual thickness may have slight variations. Additionally, it is worth noting that stainless steel sheets are also available in metric sizes. Common thicknesses in metric sizes range from 0.5 mm to 3 mm. This provides flexibility and compatibility with international standards and specifications. In summary, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements. This ensures their widespread availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: Can stainless steel sheets be used for conveyor systems?

- Yes, stainless steel sheets can be used for conveyor systems. Stainless steel is a durable and robust material that is resistant to corrosion, making it ideal for conveyor systems that may be exposed to moisture or harsh chemicals. Additionally, stainless steel is easy to clean and maintain, which is important for ensuring the hygiene and longevity of conveyor systems in industries such as food processing or pharmaceuticals. The smooth surface of stainless steel sheets also facilitates the movement of materials along the conveyor, reducing friction and improving efficiency. Overall, stainless steel sheets are a popular choice for conveyor systems due to their strength, corrosion resistance, and ease of maintenance.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Certainly! Outdoor signage or billboards can indeed utilize stainless steel sheets. Stainless steel possesses exceptional durability, effectively combating corrosion, rust, and fading. Consequently, it proves ideal for outdoor applications. It exhibits remarkable resilience against inclement weather conditions, such as rain, snow, and harmful UV rays, without compromising its integrity. Moreover, stainless steel sheets provide a sleek and contemporary aesthetic, elevating the visual allure of outdoor signage or billboards. Furthermore, stainless steel can be easily manipulated and fashioned into various shapes and sizes, empowering designers with endless possibilities for customization and innovation. In conclusion, stainless steel sheets offer a dependable and enduring choice for outdoor signage or billboards.

- Q: Can stainless steel sheets be used for elevator shafts?

- Yes, stainless steel sheets can be used for elevator shafts. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for its strength and aesthetic appeal. Elevator shafts require materials that can withstand constant use and exposure to various elements, making stainless steel an ideal choice.

- Q: What is the thermal expansion rate of stainless steel sheets?

- The thermal expansion rate of stainless steel sheets varies based on the specific grade of stainless steel and the temperature range it is exposed to. Typically, stainless steel has a coefficient of thermal expansion (CTE) of approximately 10-17 x 10^-6 per degree Celsius (µm/m°C). This implies that for each degree Celsius rise in temperature, the stainless steel sheet will expand by 10-17 micrometers per meter of length. It is worth noting that the CTE may slightly differ for various grades of stainless steel, so it is advisable to refer to the manufacturer's specifications or engineering handbooks for more accurate information regarding the thermal expansion rate of a particular stainless steel sheet.

- Q: What are the different grades of stainless steel sheets?

- There are various grades of stainless steel sheets available, each with its own unique properties and characteristics. Some commonly used grades are: - Grade 304 Stainless Steel: This grade is widely used and is known for its excellent corrosion resistance, good formability, and high strength. It finds applications in food processing equipment, kitchen appliances, and chemical containers. - Grade 316 Stainless Steel: This grade offers even better corrosion resistance compared to grade 304 stainless steel. It is often used in marine environments or applications involving exposure to corrosive chemicals. Additionally, it has good welding and forming properties. - Grade 430 Stainless Steel: This is a ferritic grade that finds use in applications requiring good corrosion resistance and moderate strength. It is commonly found in automotive trim, kitchen equipment, and decorative applications. - Grade 410 Stainless Steel: This martensitic grade provides high strength and hardness. It is commonly used in applications where wear and corrosion resistance are crucial, such as cutlery, surgical instruments, and industrial equipment. - Grade 201 Stainless Steel: This low-nickel grade offers good formability and moderate corrosion resistance. It is frequently used in decorative applications like architectural trim, appliances, and furniture. These examples highlight the range of stainless steel sheet grades available. The choice of grade depends on the specific application and desired properties, such as corrosion resistance, strength, formability, and cost.

- Q: What are the different types of stainless steel sheet finishes?

- There are several types of stainless steel sheet finishes, including No. 1, 2B, No. 4, BA, and satin.

- Q: Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a durable and versatile material that offers many advantages for façade applications. It is resistant to corrosion, weathering, and staining, making it an ideal choice for exterior use. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for a wide range of design options. Additionally, stainless steel can be finished in different ways, such as brushed, polished, or colored, providing further aesthetic possibilities. Its strength and rigidity also make it suitable for large-scale installations. Overall, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a popular choice for architectural façades.

- Q: Can stainless steel sheets be custom-cut?

- Yes, stainless steel sheets can be custom-cut to fit specific sizes and dimensions. Stainless steel is a highly versatile material that can be easily manipulated and shaped according to individual requirements. Custom-cutting stainless steel sheets is a common practice in various industries, such as construction, manufacturing, and fabrication. This process ensures that the stainless steel sheets perfectly fit the intended application, whether it is for architectural purposes, machinery parts, or kitchen appliances. Professional metal fabricators or specialized service providers typically use advanced cutting techniques, such as laser cutting, waterjet cutting, or shearing, to accurately customize stainless steel sheets to the desired specifications.

Send your message to us

Stainless Steel Sheet/Plate 304 with Low Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords