Stainless Steel Pipe Stainless Steel Tube 304/316L

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

WELCOME to visit our products here(^_^)

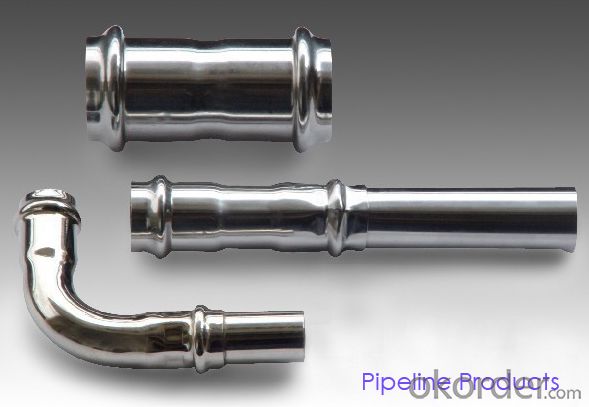

Press fitting system joins pipe without welding or bolting. The components fit by crimping through the use of a special pressing tool. An O-ring that is inserted in the fitting ends of the pipe ensures a leak-proof connection. Press fitting system is the trend of pipeline industry. It is widely used in cold and hot water supply, heating supply, fire protection, medicinal gas, industrial petroleum pipeline system etc.

For the size, now we have 3 series:

1. Out diameters: 16.0, 20.0, 25.4, 32.0, 40.0, 50.8, 63.5, 76.1, 88.9, 108.0 (GB/T 19228.2-2011)

2. Out diameters: 15.88, 22.22, 28.58, 34.0, 42.7, 48.6, 76.1, 88.9, 101.6 (JIS G3448-1980)

3. Out diameters: 15, 18, 22, 28, 35, 42, 54, 76.1, 88.9, 108 (EN 10312:2002)

Technical information:

-- Material: Stainless steel 304 and 316L available.

-- Max working pressure 1.6MPa (equal to 232 psi), testing water pressure: 2.5MPa (equal to 362.5psi).

-- Working temperature from -20 to 110 degree centigrade (with Chlorinated butyl rubber O ring),

-- Suit medium: Cold water, hot water, compressed air, gas, oil etc

The product features as below:

1, thin wall stainless steel pipe could last for 70 years, it is the same life time with normal buildings.

2, no smell, no rusty.

3, recycle material

4, avoid welding, avoid fire dangerous.

Contact us for more details!

- Q: Can stainless steel pipes be used for refrigeration systems?

- Indeed, refrigeration systems can utilize stainless steel pipes. Stainless steel, being an exceedingly robust material, exhibits exceptional resistance against corrosion, rendering it perfectly suitable for deployment in refrigeration systems where both moisture and low temperatures are prevalent. Moreover, stainless steel pipes boast remarkable thermal conductivity, facilitating efficient and effective heat transfer throughout the entire system. Furthermore, stainless steel pipes are effortlessly cleanable and maintainable, while also demonstrating the capacity to withstand significant pressure, thereby making them highly appropriate for deployment in refrigeration systems necessitating unwavering and enduring performance.

- Q: Are stainless steel pipes suitable for fire protection systems?

- Yes, stainless steel pipes are suitable for fire protection systems. Stainless steel has excellent fire resistance properties, including high melting point and resistance to corrosion and oxidation. These pipes are highly durable and can withstand extreme temperatures and pressure, making them ideal for fire protection systems that require reliable and long-lasting performance. Additionally, stainless steel pipes have low thermal conductivity, which helps to minimize heat loss during a fire event.

- Q: Does stainless steel pipe belong to hardware?

- Belong to. Hardware: refers to gold, silver, copper, iron, tin, five metal materials called. Stainless steel pipe is a kind of hollow long strip round steel.

- Q: What is the difference between Type 304L and Type 316L stainless steel pipes?

- Type 304L and Type 316L stainless steel pipes are both popular choices for various applications due to their corrosion-resistant properties. However, they differ in their composition and performance in specific environments. The main difference lies in their alloy content. Type 304L stainless steel contains 18-20% chromium and 8-12% nickel, while Type 316L stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum in Type 316L enhances its resistance to corrosion, particularly in chloride-rich environments. This makes Type 316L more suitable for applications where the pipes will be exposed to seawater, brine, or other aggressive chemicals. Another distinguishing factor is their mechanical properties. Type 316L stainless steel has slightly higher tensile strength and yield strength compared to Type 304L. It also exhibits better creep and stress rupture properties, making it more suitable for high-temperature applications. However, Type 304L is still a good choice for most general-purpose applications and offers excellent durability and longevity. In terms of cost, Type 316L stainless steel pipes are generally more expensive than Type 304L due to the added alloying elements. Therefore, the choice between the two will depend on the specific requirements of the application, considering factors such as the corrosive environment, temperature, and budget. Overall, while both Type 304L and Type 316L stainless steel pipes offer excellent corrosion resistance, Type 316L provides superior performance in more aggressive environments and higher temperatures. It is important to consult with a materials expert or engineer to determine the most suitable stainless steel pipe for a specific application.

- Q: Is stainless steel flexible enough for plumbing applications?

- Yes, stainless steel is flexible enough for plumbing applications. Stainless steel pipes and fittings are known for their durability and strength, but they also offer a certain degree of flexibility. This flexibility allows for easier installation in various plumbing systems, including those with complex layouts or tight spaces. Stainless steel pipes can be bent and shaped without compromising their structural integrity, making them suitable for both residential and commercial plumbing projects. Additionally, stainless steel is highly resistant to corrosion, which is crucial for plumbing applications where exposure to water and other corrosive substances is common. Overall, stainless steel's combination of strength, durability, and flexibility makes it an excellent choice for plumbing applications.

- Q: What is the difference between martensitic and precipitation-hardening stainless steel pipes?

- Martensitic and precipitation-hardening stainless steel pipes are two different types of stainless steel alloys that offer distinct characteristics and properties. Martensitic stainless steel pipes are known for their high strength and hardness. They are formed by quenching and tempering, a process that involves rapid cooling followed by reheating to achieve the desired properties. This type of stainless steel is magnetic and can be heat-treated to further enhance its strength. Martensitic stainless steel pipes are commonly used in applications where high mechanical strength, such as in automotive parts or cutlery, is required. On the other hand, precipitation-hardening stainless steel pipes are alloyed with elements like copper, aluminum, or titanium. The addition of these elements allows for the formation of precipitates during heat treatment, resulting in increased strength and corrosion resistance. Precipitation-hardening stainless steel pipes also offer good weldability and can be easily machined. They are typically used in industries such as aerospace, oil and gas, and chemical processing, where a combination of strength and corrosion resistance is crucial. In summary, the main difference between martensitic and precipitation-hardening stainless steel pipes lies in their composition and the heat treatment processes involved. Martensitic stainless steel pipes are hardened through quenching and tempering, offering high strength and hardness, while precipitation-hardening stainless steel pipes are strengthened through the formation of precipitates during heat treatment, providing a balance of strength and corrosion resistance.

- Q: Stainless steel pipe 301 material and 304 material what is the difference?

- 304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability)

- Q: Are stainless steel pipes suitable for underground sewage systems?

- Certainly, underground sewage systems benefit greatly from the use of stainless steel pipes. Renowned for their resilience, robustness, and resistance to corrosion, stainless steel pipes prove to be an optimal selection for subterranean applications. With an extended lifespan, they can endure the demanding circumstances commonly encountered in sewage systems, such as exposure to moisture, chemicals, and fluctuating temperatures. Furthermore, the smooth interior surface of stainless steel pipes serves to prevent the accumulation of debris or waste, effectively decreasing the likelihood of clogs or obstructions. In summary, stainless steel pipes present a dependable and enduring solution for underground sewage systems.

- Q: Can stainless steel pipes be insulated with polyethylene naphthalate?

- Indeed, polyethylene naphthalate (PEN) is a viable option for insulating stainless steel pipes. PEN, a top-notch thermoplastic material, boasts impressive insulation capabilities. Its low thermal conductivity qualifies it to effectively insulate pipes, guarding against heat loss or gain. Moreover, PEN exhibits commendable resistance to chemicals, moisture, and UV radiation, making it a robust choice for pipe insulation. Nevertheless, it is crucial to verify the compatibility of the chosen insulation material with the unique application and operating conditions to guarantee optimal performance and durability.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- The method of non direct fusion is adopted, such as blue, silk head and movable joint.

Send your message to us

Stainless Steel Pipe Stainless Steel Tube 304/316L

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords